The evolution of spur gear use in the automotive industry is a testament to the ongoing advancements in automotive engineering and manufacturing technologies. Spur gear, with their simple yet robust design, have played a crucial role in the development of automotive mechanisms. Let’s explore the historical progression and how spur gear have adapted to changing industry needs.

Early Beginnings and Adaptation

- Early 20th Century: Initially, spur gear were widely used in the automotive industry due to their simplicity and effectiveness in transmitting power between parallel shafts. They were fundamental in early gearbox designs.

- Design Simplicity: The straightforward design of spur gear made them easy to manufacture with the technology available at the time, facilitating their use in early automobiles.

Mid-20th Century Developments

- Increase in Vehicle Performance Requirements: As automobiles became more common and demands on performance increased, the limitations of spur gear became apparent. Their tendency to generate noise and vibration at high speeds led to the exploration of alternative designs, such as helical gear.

- Continued Use in Low-Speed Applications: Despite these limitations, spur gear continued to be used in areas where noise was not a critical factor, or where the simplicity and cost-efficiency of spur gear were paramount, such as in farm machinery and heavy vehicles.

Late 20th Century Innovations

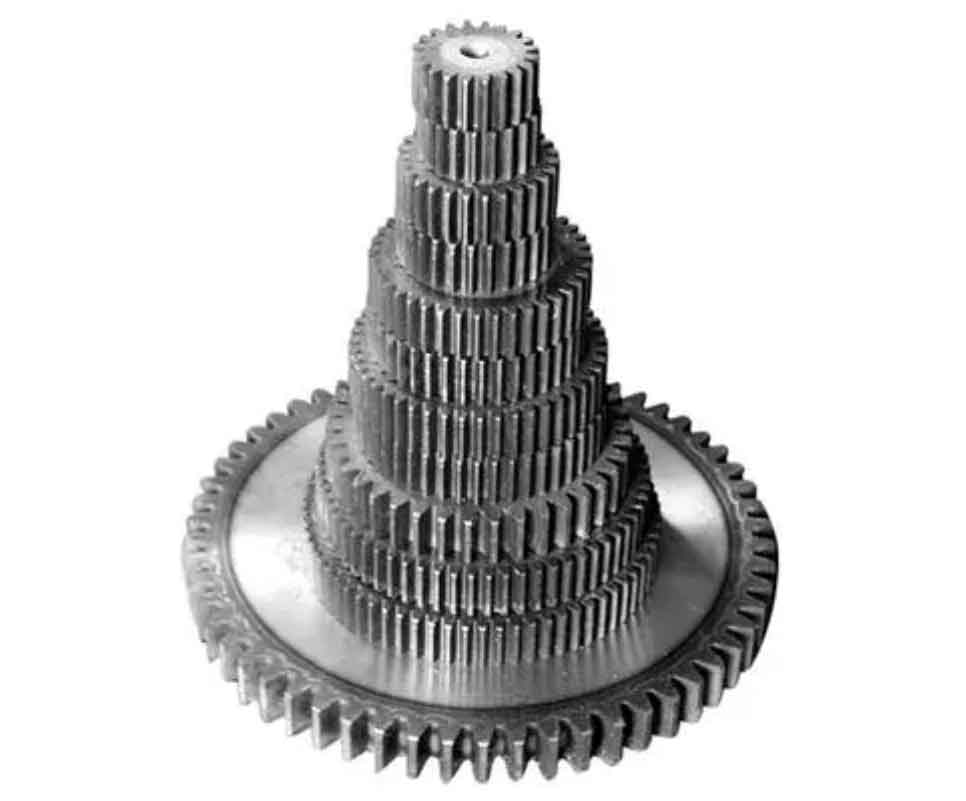

- Material and Manufacturing Advances: Advancements in materials science led to the development of more durable and robust gear. High-strength steel alloys and precision manufacturing techniques improved the load-bearing capacity and life expectancy of spur gear.

- Specialized Applications: Spur gear found their niche in specific automotive applications where high precision and reliability were necessary, such as in oil pumps and other auxiliary systems.

Modern Applications and Technologies

- Precision and Miniaturization: With advancements in CNC technology and materials engineering, modern spur gear is manufactured with much tighter tolerances and can be used in more compact and high-precision applications.

- Hybrid and Electric Vehicles: In hybrid and electric vehicles, spur gear is utilized in differentials and transmissions where their efficiency and durability contribute to better energy management and longevity of the vehicle.

- Noise Reduction Technologies: Innovations such as micro-geometry adjustments and advanced lubrication systems have mitigated the noise issues associated with spur gear, making them more viable at higher speeds.

Future Prospects

- Continued Material Innovations: The development of composite materials and metal matrix composites will likely play a significant role in the future of spur gear in automotive applications, offering reductions in weight and improvements in efficiency.

- Integration with Advanced Systems: As vehicles become more integrated with advanced electronic control systems, spur gear will need to adapt to more precise and variable operating conditions, potentially leading to new designs that incorporate smart materials capable of altering characteristics in response to environmental changes.

Conclusion

The evolution of spur gear in the automotive industry highlights their adaptability and enduring relevance. Despite the advent of more complex gear designs, the simplicity, cost-effectiveness, and reliability of spur gear ensure their continued use in both traditional and innovative automotive applications. As the industry moves towards more sustainable and high-efficiency models, the spur gear will undoubtedly continue to evolve to meet these new challenges.