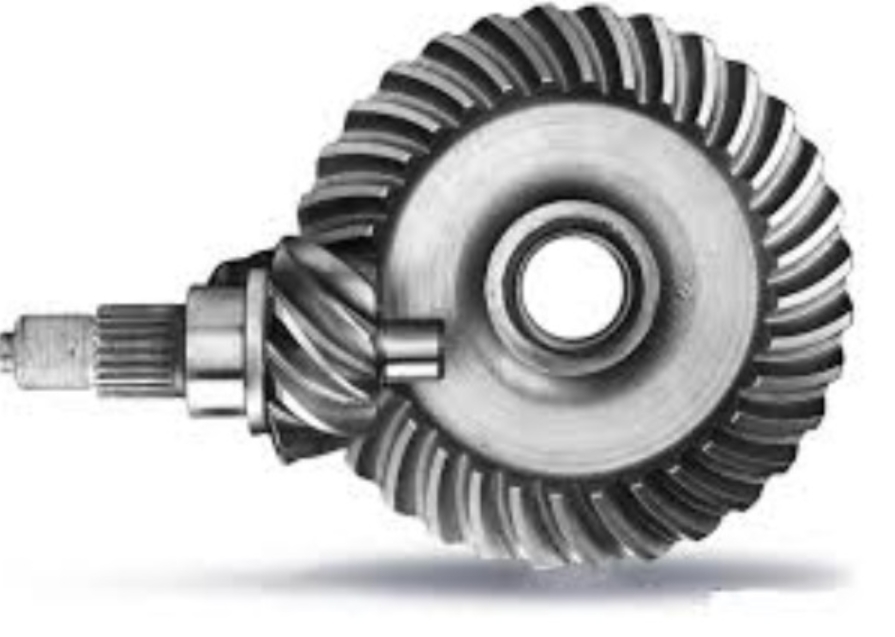

Advancements in hypoid gear manufacturing have primarily focused on improving precision machining processes to enhance the performance, efficiency, and durability of these gears. Hypoid gear is commonly used in automotive and industrial applications where high torque transmission is required at non-intersecting and non-parallel axes. Here are some innovations in precision machining that have contributed to advancements in hypoid gear manufacturing:

1. Computer-Aided Design (CAD) and Simulation

- Virtual Modeling: CAD software allows for precise design and simulation of hypoid gear, ensuring optimal tooth geometry and contact patterns.

- Finite Element Analysis (FEA): FEA is used to simulate gear meshing and analyze stress distribution, helping optimize gear designs for strength and durability.

2. CNC Machining

- High-Precision Machining: Computer Numerical Control (CNC) machines offer high precision in cutting hypoid gear teeth, ensuring accurate tooth profiles and surface finishes.

- 5-Axis Machining: 5-axis CNC machines enable simultaneous machining of complex gear geometries, reducing production time and improving accuracy.

3. Gear Grinding

- Precision Grinding: Gear grinding processes, such as generating grinding and form grinding, are used to achieve high precision in tooth profiles and surface finishes.

- Continuous Generating Grinding: This method allows for high-speed and high-precision production of hypoid gear with improved surface quality.

4. Advanced Cutting Tools

- Carbide Tools: High-performance carbide cutting tools are used for machining hypoid gear, offering superior wear resistance and cutting performance.

- Coated Tools: Coatings like TiN, TiAlN, and DLC are applied to cutting tools to enhance their wear resistance and tool life.

5. Optical Metrology

- Gear Inspection: Optical metrology systems are used for accurate and non-contact measurement of hypoid gear tooth profiles, ensuring they meet design specifications.

- Surface Inspection: Optical systems are also used to inspect gear surfaces for defects and deviations from the desired finish.

6. Automation and Robotics

- Automated Gear Manufacturing Cells: Integration of robotics and automation in gear manufacturing cells improves process efficiency and consistency.

- Robotic Inspection: Robots are used for automated inspection of hypoid gear tooth profiles and dimensions, ensuring high quality and consistency.

7. Laser Machining

- Laser Cutting: Laser cutting is used for precision cutting of hypoid gear blanks and for creating features like keyways and splines with high accuracy.

- Laser Hardening: Laser hardening is employed to selectively harden gear tooth surfaces, improving wear resistance and durability.

8. Process Simulation and Optimization

- Virtual Prototyping: Simulation software is used to optimize machining processes and tool paths for improved efficiency and reduced production time.

- Process Monitoring: Real-time monitoring of machining processes allows for adjustments to be made to optimize performance and ensure quality.

By leveraging these advancements in precision machining, manufacturers can produce hypoid gear with higher precision, efficiency, and durability, meeting the stringent requirements of modern automotive and industrial applications.