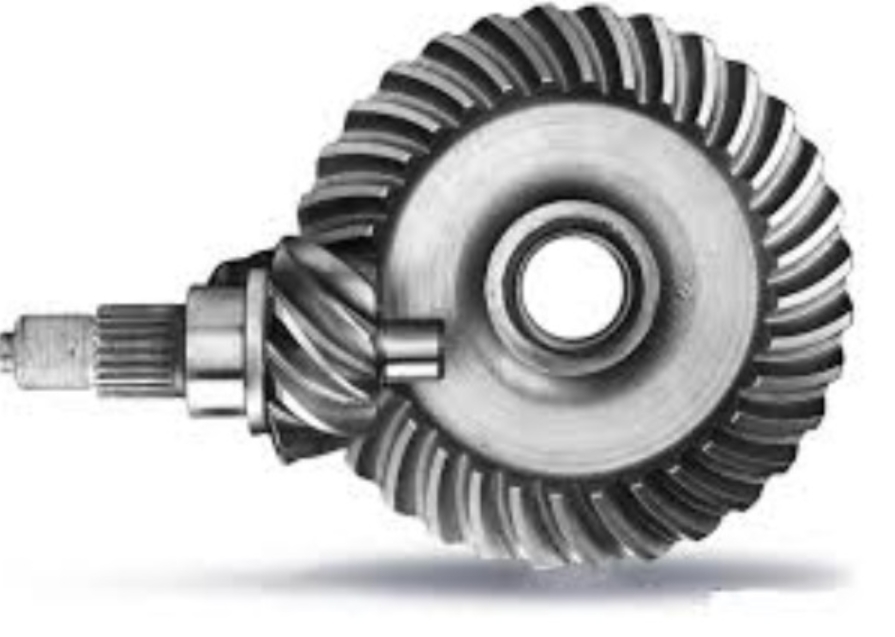

Hypoid gear is type of spiral bevel gear whose axes do not intersect. These gears are commonly used in automotive differentials and heavy machinery due to their ability to transmit power efficiently while reducing noise and vibration. Optimizing the manufacturing processes of hypoid gear is crucial for achieving precision, quality, and cost-effectiveness. This article explores various aspects and strategies for optimizing hypoid gear manufacturing.

Precision in Hypoid Gear Manufacturing

Achieving high precision in hypoid gear manufacturing involves several critical steps:

- Design Optimization: Utilizing advanced CAD/CAM software to design hypoid gear with precise specifications.

- Material Selection: Choosing high-quality materials that exhibit minimal deformation and wear.

- Machining Accuracy: Implementing precise machining techniques such as CNC milling and grinding.

- Heat Treatment: Applying controlled heat treatment processes to enhance material properties and dimensional stability.

Quality Assurance in Hypoid Gear Manufacturing

Maintaining quality throughout the manufacturing process is essential to produce reliable hypoid gear. Key quality assurance measures include:

- Inspection and Testing: Regular inspection of hypoid gear using CMM (Coordinate Measuring Machines) and other advanced metrology tools.

- Surface Finishing: Ensuring smooth surface finishes to reduce friction and wear.

- Assembly Precision: Maintaining tight tolerances during assembly to ensure proper hypoid gear meshing and performance.

- Process Control: Implementing Statistical Process Control (SPC) to monitor and control manufacturing processes.

Cost-Effectiveness in Hypoid Gear Manufacturing

Balancing precision and quality with cost-effectiveness is a critical challenge. Strategies to achieve this balance include:

- Lean Manufacturing: Adopting lean manufacturing principles to minimize waste and enhance efficiency.

- Automation: Utilizing automated machinery and robotics to increase production speed and reduce labor costs.

- Supplier Integration: Collaborating with suppliers for timely and cost-effective procurement of materials and components.

- Continuous Improvement: Implementing continuous improvement practices such as Kaizen to constantly refine and optimize processes.

Table: Key Strategies for Optimizing Hypoid Gear Manufacturing

| Strategy | Description | Benefits |

|---|---|---|

| Design Optimization | Utilizing advanced CAD/CAM software for precise gear design | High precision and accurate gear geometry |

| Material Selection | Choosing high-quality materials | Enhanced durability and reduced wear |

| Machining Accuracy | Implementing precise CNC milling and grinding techniques | Improved gear accuracy and consistency |

| Heat Treatment | Controlled heat treatment processes | Enhanced material properties and stability |

| Inspection and Testing | Regular use of advanced metrology tools | Ensured quality and reliability of gears |

| Surface Finishing | Achieving smooth surface finishes | Reduced friction and extended gear life |

| Assembly Precision | Maintaining tight tolerances during assembly | Proper gear meshing and optimal performance |

| Process Control | Implementing Statistical Process Control (SPC) | Consistent manufacturing quality |

| Lean Manufacturing | Adopting lean principles to minimize waste | Increased efficiency and cost savings |

| Automation | Using automated machinery and robotics | Higher production speed and reduced labor costs |

| Supplier Integration | Collaborating with suppliers for timely material procurement | Cost-effective material and component sourcing |

| Continuous Improvement | Implementing continuous improvement practices like Kaizen | Ongoing process refinement and optimization |

Conclusion

Optimizing hypoid gear manufacturing processes is essential for producing high-quality, precise, and cost-effective gears. By focusing on design optimization, material selection, machining accuracy, heat treatment, quality assurance, and cost-effective manufacturing strategies, manufacturers can enhance the performance and longevity of hypoid gear. Adopting advanced technologies and continuous improvement practices will further drive efficiency and innovation in the manufacturing of hypoid gear.