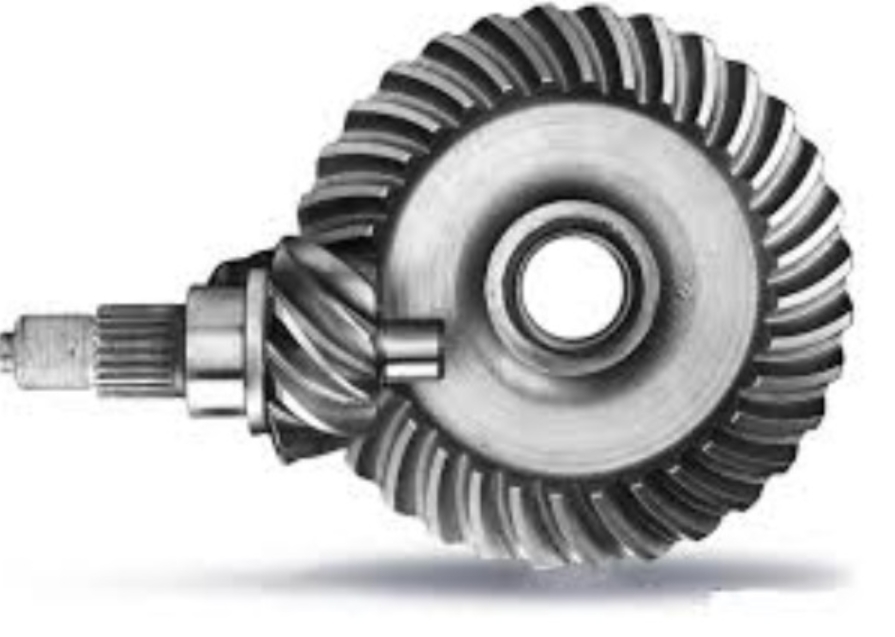

Hypoid gear is type of bevel gear where the axes of the two shafts do not intersect. They are commonly used in automotive differentials and other high-performance applications due to their high efficiency and ability to transmit significant torque. However, the complex geometry and high-contact stresses of hypoid gear pose unique challenges for lubrication. This article explores various innovative lubrication techniques to enhance the performance and longevity of hypoid gear.

Introduction

Lubrication is critical in reducing friction, wear, and heat generation in hypoid gear. Traditional lubrication methods, while effective, may not always provide optimal performance under extreme conditions. Therefore, innovative lubrication techniques are essential for improving the reliability and efficiency of hypoid gear systems.

Types of Lubricants for Hypoid Gear

- Mineral Oils: Widely used due to their availability and cost-effectiveness. They provide adequate lubrication but may require frequent changes under high-stress conditions.

- Synthetic Oils: Offer superior performance, especially at extreme temperatures. They have better oxidation stability and longer service life.

- Bio-based Lubricants: Environmentally friendly alternatives that provide comparable performance to traditional lubricants.

- Additive-Enhanced Lubricants: Contain additives such as anti-wear agents, extreme pressure agents, and friction modifiers to enhance performance.

Innovative Lubrication Techniques

1. Solid Lubricants

Solid lubricants, such as graphite and molybdenum disulfide, can be applied as coatings or incorporated into the lubricant matrix. These materials provide a low-friction surface and can sustain lubrication even under boundary lubrication conditions.

2. Nano-Lubricants

Nano-lubricants incorporate nanoparticles, such as nanodiamonds, fullerenes, or metal oxides, into the lubricant. These particles enhance load-carrying capacity, reduce friction, and improve thermal conductivity, leading to better overall performance.

3. Magnetorheological (MR) Fluids

MR fluids change their viscosity in the presence of a magnetic field. This property can be exploited to create adaptive lubrication systems that adjust the lubricant’s properties in real-time to match the operating conditions of the hypoid gear.

4. Ionic Liquids

Ionic liquids are salts in a liquid state that possess unique properties, such as low volatility and high thermal stability. They can form robust tribofilms on hypoid gear surfaces, significantly reducing wear and friction.

Comparative Analysis of Lubrication Techniques

| Lubrication Technique | Advantages | Disadvantages |

|---|---|---|

| Solid Lubricants | Low friction, effective under high loads | May require frequent reapplication |

| Nano-Lubricants | Enhanced load capacity, thermal stability | High cost, complex formulation |

| Magnetorheological Fluids | Adaptive to conditions, controllable | Requires external magnetic field source |

| Ionic Liquids | High thermal stability, low volatility | Expensive, limited availability |

Factors Affecting Lubrication Performance

- Operating Temperature: Higher temperatures can degrade lubricant properties, making thermal stability a critical factor.

- Load Conditions: Heavy loads increase contact stresses, requiring lubricants with high load-carrying capacity.

- Speed: Higher speeds increase the shear rate, influencing the viscosity and film formation ability of the lubricant.

- Environmental Conditions: Exposure to contaminants and moisture can affect lubricant performance and require specialized formulations.

Future Directions

The future of hypoid gear lubrication lies in the development of smart lubricants and lubrication systems. These systems will be able to monitor operating conditions in real-time and adjust lubrication parameters accordingly. Research into bio-based and environmentally friendly lubricants is also gaining momentum, driven by sustainability goals.

Conclusion

Innovative lubrication techniques are essential for optimizing the performance and durability of hypoid gear. By incorporating advanced materials and smart technologies, it is possible to achieve significant improvements in gear efficiency and lifespan. As research progresses, these techniques will become more accessible and cost-effective, paving the way for their widespread adoption in various industrial applications.