Introduction

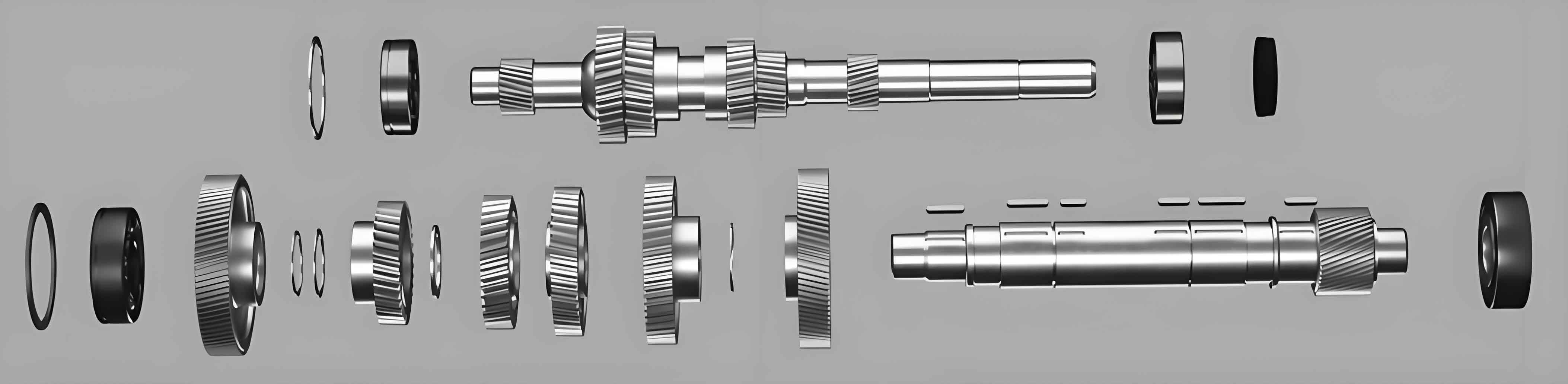

Gear Shaft is integral components in high-performance transmission systems. These shaft is responsible for transmitting torque and rotational power between different gears, ensuring the smooth operation of the transmission system. The performance, durability, and efficiency of high-performance transmission systems heavily rely on the quality and design of the Gear Shaft. This article explores the critical role Gear Shaft play in high-performance transmission systems, including their functions, materials used, design considerations, and common challenges.

Functions of Gear Shaft in High-Performance Transmission Systems

- Torque Transmission: Gear Shaft transfer torque from one gear to another, enabling the transmission of power within the system.

- Rotational Motion Transfer: Gear Shaft facilitate the transfer of rotational motion between gears, ensuring synchronized movement.

- Support and Alignment: Gear Shaft provide support to the gears and maintain their alignment, which is crucial for the smooth operation of the transmission system.

- Load Bearing: Gear Shaft bear the loads applied to the gears during operation, ensuring stability and reliability.

Key Requirements for Gear Shaft in High-Performance Transmission Systems

- High Strength: Gear Shaft must possess high tensile and shear strength to withstand the loads and stresses encountered during operation.

- Durability: Gear Shaft should be durable enough to resist wear and fatigue over prolonged periods of use.

- Precision: Manufacturing precision is essential to ensure the proper alignment and smooth operation of the transmission system.

- Heat Resistance: High-performance transmission systems generate significant heat; thus, Gear Shaft must maintain their integrity under high temperatures.

Common Materials Used for Gear Shaft

1. High-Strength Steels

High-strength steels are widely used for Gear Shaft due to their excellent mechanical properties.

Characteristics:

- High tensile and shear strength.

- Good wear resistance.

- Moderate cost and good machinability.

Applications:

- Automotive transmission systems.

- Heavy machinery.

Properties:

| Property | Value |

|---|---|

| Tensile Strength | 600-900 MPa |

| Hardness (HRC) | 30-50 |

| Wear Resistance | High |

| Fatigue Resistance | High |

2. Alloy Steels

Alloy steels, containing elements like chromium, molybdenum, and nickel, offer enhanced properties.

Characteristics:

- High strength and toughness.

- Excellent fatigue and wear resistance.

- Higher cost compared to standard steels.

Applications:

- High-stress applications in automotive and industrial sectors.

Properties:

| Property | Value |

|---|---|

| Tensile Strength | 700-1000 MPa |

| Hardness (HRC) | 35-55 |

| Wear Resistance | Very High |

| Fatigue Resistance | Very High |

3. Titanium Alloys

Titanium alloys are used in applications where weight reduction is crucial without compromising strength.

Characteristics:

- High strength-to-weight ratio.

- Excellent corrosion resistance.

- Expensive and difficult to machine.

Applications:

- Aerospace and high-performance automotive systems.

Properties:

| Property | Value |

|---|---|

| Tensile Strength | 800-1100 MPa |

| Hardness (HRC) | 30-40 |

| Wear Resistance | Moderate |

| Fatigue Resistance | High |

Design Considerations for Gear Shaft

- Load Analysis: Understanding the types and magnitudes of loads the Gear Shaft will encounter is critical for design.

- Material Selection: Choosing the right material based on strength, durability, and application-specific requirements.

- Heat Treatment: Implementing appropriate heat treatment processes to enhance the mechanical properties of the Gear Shaft.

- Surface Finishing: Applying surface finishing techniques to improve wear resistance and reduce friction.

- Precision Manufacturing: Ensuring high precision in the manufacturing process to maintain tight tolerances and proper alignment.

Common Challenges in Gear Shaft Design and Operation

- Fatigue Failure: Repeated loading cycles can lead to fatigue failure, which must be mitigated through proper material selection and heat treatment.

- Wear and Tear: Continuous contact and friction can cause wear, necessitating the use of wear-resistant materials and coatings.

- Misalignment: Any misalignment in the Gear Shaft can lead to inefficient power transmission and increased wear.

- Thermal Stress: High temperatures generated during operation can cause thermal stress, requiring materials that maintain integrity under heat.

Enhancing Gear Shaft Performance

1. Advanced Materials

Using advanced materials like high-strength alloys and composites can significantly enhance the performance of Gear Shaft.

2. Heat Treatment Processes

Heat treatment processes such as carburizing, nitriding, and induction hardening can improve the surface hardness and overall strength of Gear Shaft.

3. Surface Coatings

Applying surface coatings like titanium nitride or diamond-like carbon can reduce friction and wear, extending the Gear Shaft’s lifespan.

4. Precision Manufacturing Techniques

Employing precision manufacturing techniques such as CNC machining ensures high accuracy and consistency in Gear Shaft production.

Comparative Analysis of Gear Shaft Materials

| Property | High-Strength Steels | Alloy Steels | Titanium Alloys |

|---|---|---|---|

| Tensile Strength | 600-900 MPa | 700-1000 MPa | 800-1100 MPa |

| Hardness (HRC) | 30-50 | 35-55 | 30-40 |

| Wear Resistance | High | Very High | Moderate |

| Fatigue Resistance | High | Very High | High |

| Corrosion Resistance | Moderate | High | Excellent |

| Cost | Moderate | High | Very High |

| Machinability | Good | Moderate | Challenging |

Conclusion

Gear Shaft is pivotal components in high-performance transmission systems, impacting their efficiency, reliability, and longevity. The choice of materials, precision in design, and advanced manufacturing techniques all play critical roles in enhancing the performance of Gear Shaft. By understanding the specific requirements and challenges associated with high-performance transmission systems, engineers can make informed decisions to optimize Gear Shaft performance, ensuring smooth and efficient power transmission across various applications.