Introduction

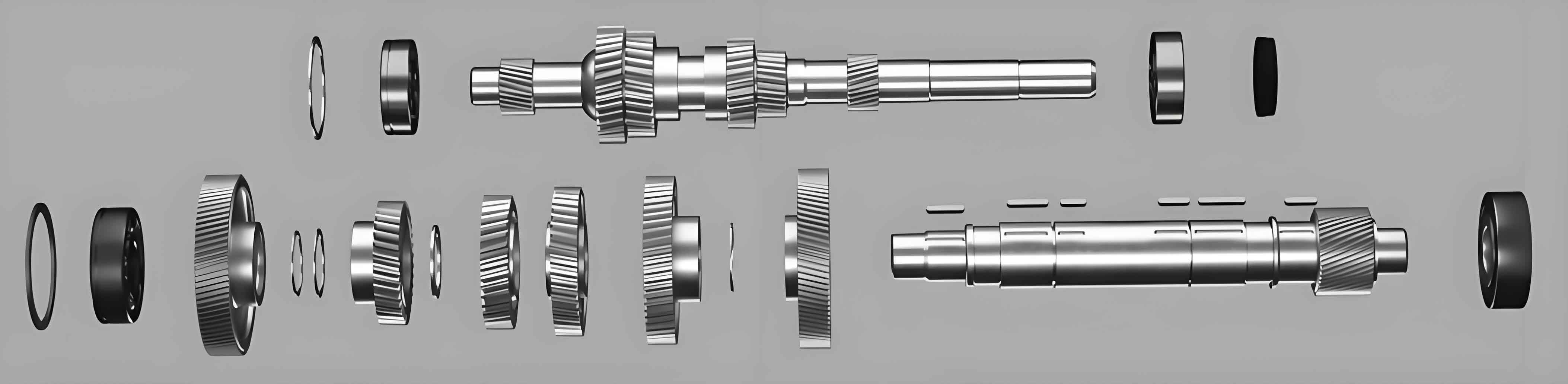

Non-Destructive Testing (NDT) techniques play a crucial role in ensuring the quality and reliability of Gear Shaft. These methods allow for the inspection and evaluation of Gear Shaft without causing any damage, making them indispensable in quality assurance processes. This article explores the various NDT techniques used for Gear Shaft quality assurance, highlighting their importance, methodologies, and the benefits they offer in maintaining high standards in manufacturing and operational integrity.

Importance of Non-Destructive Testing for Gear Shaft

- Ensuring Structural Integrity: NDT techniques help in identifying internal and surface defects that could compromise the structural integrity of Gear Shaft.

- Preventing Failures: Early detection of flaws and irregularities prevents potential failures during operation, enhancing the reliability of the Gear Shaft.

- Cost-Efficiency: By identifying defects early in the manufacturing process, NDT reduces the need for costly repairs and replacements.

- Compliance with Standards: NDT ensures that Gear Shaft meet industry standards and specifications, which is critical for safety and performance.

Key Non-Destructive Testing Techniques for Gear Shaft

1. Ultrasonic Testing (UT)

Methodology:

- High-frequency sound waves are transmitted into the Gear Shaft.

- Reflected waves are analyzed to detect internal defects and discontinuities.

Advantages:

- Detects both surface and subsurface defects.

- Provides precise measurements of defect size and location.

- Suitable for a wide range of materials.

Applications:

- Detecting cracks, voids, and inclusions in Gear Shaft.

Table: Ultrasonic Testing Parameters

| Parameter | Description |

|---|---|

| Frequency Range | 0.5 to 25 MHz |

| Penetration Depth | Up to several meters (depending on material) |

| Sensitivity | High |

| Resolution | High |

2. Magnetic Particle Testing (MPT)

Methodology:

- The Gear Shaft is magnetized, and ferromagnetic particles are applied to the surface.

- Particles gather around surface and near-surface defects, making them visible.

Advantages:

- Quick and relatively easy to perform.

- Effective for detecting surface and slightly subsurface defects.

- Can be used on complex shapes and sizes.

Applications:

- Identifying surface cracks, seams, and inclusions in ferromagnetic Gear Shaft.

Table: Magnetic Particle Testing Parameters

| Parameter | Description |

|---|---|

| Magnetic Field Strength | Variable (depending on material and defect type) |

| Sensitivity | High for surface defects |

| Inspection Time | Short |

| Surface Condition | Clean, free of oil and grease |

3. Dye Penetrant Testing (DPT)

Methodology:

- A dye penetrant is applied to the surface of the Gear Shaft.

- Excess dye is removed, and a developer is applied to draw out the dye from defects.

Advantages:

- Simple and cost-effective.

- Highly sensitive to surface defects.

- Can be used on non-ferrous and ferrous materials.

Applications:

- Detecting surface cracks, porosity, and other surface-breaking defects.

Table: Dye Penetrant Testing Parameters

| Parameter | Description |

|---|---|

| Dye Type | Visible or fluorescent |

| Sensitivity | High for surface defects |

| Inspection Time | Moderate |

| Surface Condition | Clean, smooth |

4. Radiographic Testing (RT)

Methodology:

- X-rays or gamma rays are passed through the Gear Shaft.

- The resulting image is analyzed for internal defects.

Advantages:

- Provides a permanent record of the inspection.

- Can detect both surface and internal defects.

- Suitable for complex and thick sections.

Applications:

- Identifying internal voids, cracks, and inclusions.

Table: Radiographic Testing Parameters

| Parameter | Description |

|---|---|

| Radiation Type | X-rays or gamma rays |

| Penetration Depth | High (depending on material thickness) |

| Sensitivity | High |

| Resolution | High |

5. Eddy Current Testing (ECT)

Methodology:

- Alternating current is passed through a coil, generating an eddy current field in the Gear Shaft.

- Disruptions in the eddy current flow are analyzed to detect defects.

Advantages:

- Suitable for surface and near-surface defect detection.

- High sensitivity and accuracy.

- Can be automated for continuous inspection.

Applications:

- Detecting surface cracks, corrosion, and conductivity variations.

Table: Eddy Current Testing Parameters

| Parameter | Description |

|---|---|

| Frequency Range | 100 Hz to 1 MHz |

| Sensitivity | High for surface defects |

| Penetration Depth | Limited to surface and near-surface |

| Inspection Speed | Fast |

Comparative Analysis of Non-Destructive Testing Techniques

| Technique | Type of Defects Detected | Penetration Depth | Cost | Complexity | Applications |

|---|---|---|---|---|---|

| Ultrasonic Testing | Surface and subsurface | High | Moderate to High | Moderate | Cracks, voids, inclusions |

| Magnetic Particle Testing | Surface and near-surface | Low | Low | Low | Surface cracks, seams, inclusions |

| Dye Penetrant Testing | Surface | Very low | Low | Low | Surface cracks, porosity |

| Radiographic Testing | Surface and internal | High | High | High | Internal voids, cracks, inclusions |

| Eddy Current Testing | Surface and near-surface | Low to Moderate | Moderate | Moderate | Surface cracks, corrosion, conductivity variations |

Benefits of Non-Destructive Testing for Gear Shaft Quality Assurance

- Enhanced Reliability: Early detection of defects ensures that only high-quality Gear Shaft is used in critical applications.

- Extended Service Life: Identifying and addressing defects before they cause failures can significantly extend the service life of Gear Shaft.

- Safety: Ensuring the integrity of Gear Shaft enhances the safety of the overall mechanical system.

- Cost Savings: Preventing failures and reducing the need for repairs and replacements lead to significant cost savings over time.

- Compliance with Standards: Regular NDT inspections ensure that Gear Shaft meet industry standards and regulatory requirements.

Conclusion

Non-Destructive Testing techniques are essential for ensuring the quality and reliability of Gear Shaft. Each technique offers unique advantages and is suited for detecting specific types of defects. By employing a combination of NDT methods, manufacturers can achieve comprehensive quality assurance, ensuring that Gear Shaft meet the highest standards of performance and safety. Through regular and thorough NDT inspections, the lifespan of Gear Shaft can be extended, operational reliability can be enhanced, and significant cost savings can be realized.