Abstract

This paper proposes an intelligent fault diagnosis method for spiral bevel gearboxes based on Gramian Angular Difference Field (GADF) and Hybrid Whale-Particle Swarm Optimization Algorithm (HWP) with Convolutional Block Attention Module-ResNet (CBAM-ResNet). The method addresses the low accuracy of ResNet in complex noise and the limitations of traditional optimization algorithms. It involves overlapping sampling, GADF encoding, adding CBAM to ResNet, and using HWP for optimization. Experimental results show high accuracy and strong robustness, with a 100% accuracy rate in normal conditions and 95.38% in complex noise.

1. Data Preprocessing

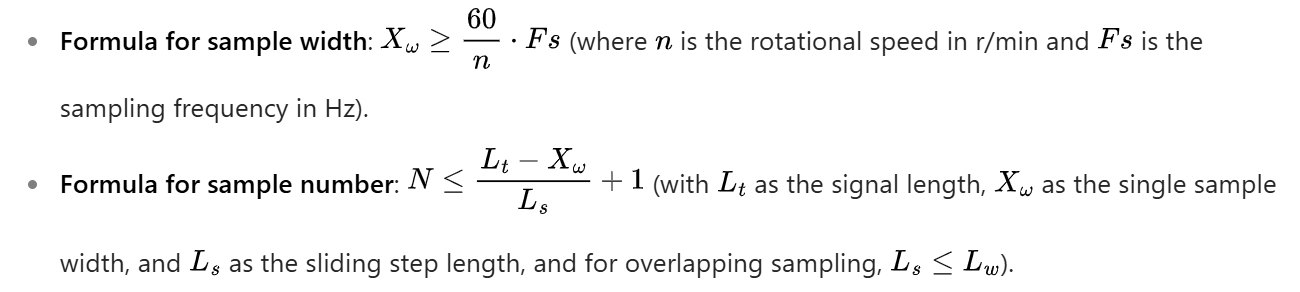

1.1 Overlapping Sampling Expansion Method

- Formula for sample number: (with as the signal length, as the single sample width, and as the sliding step length, and for overlapping sampling, ).

1.2 Gramian Angular Difference Field (GADF)

2. Fault Diagnosis Model Building

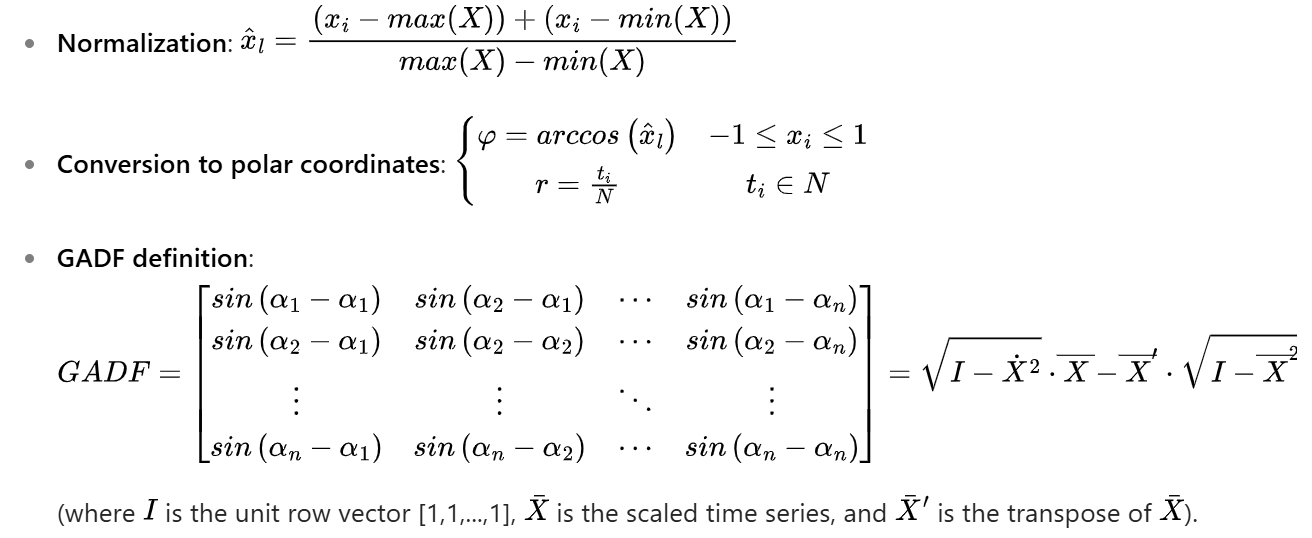

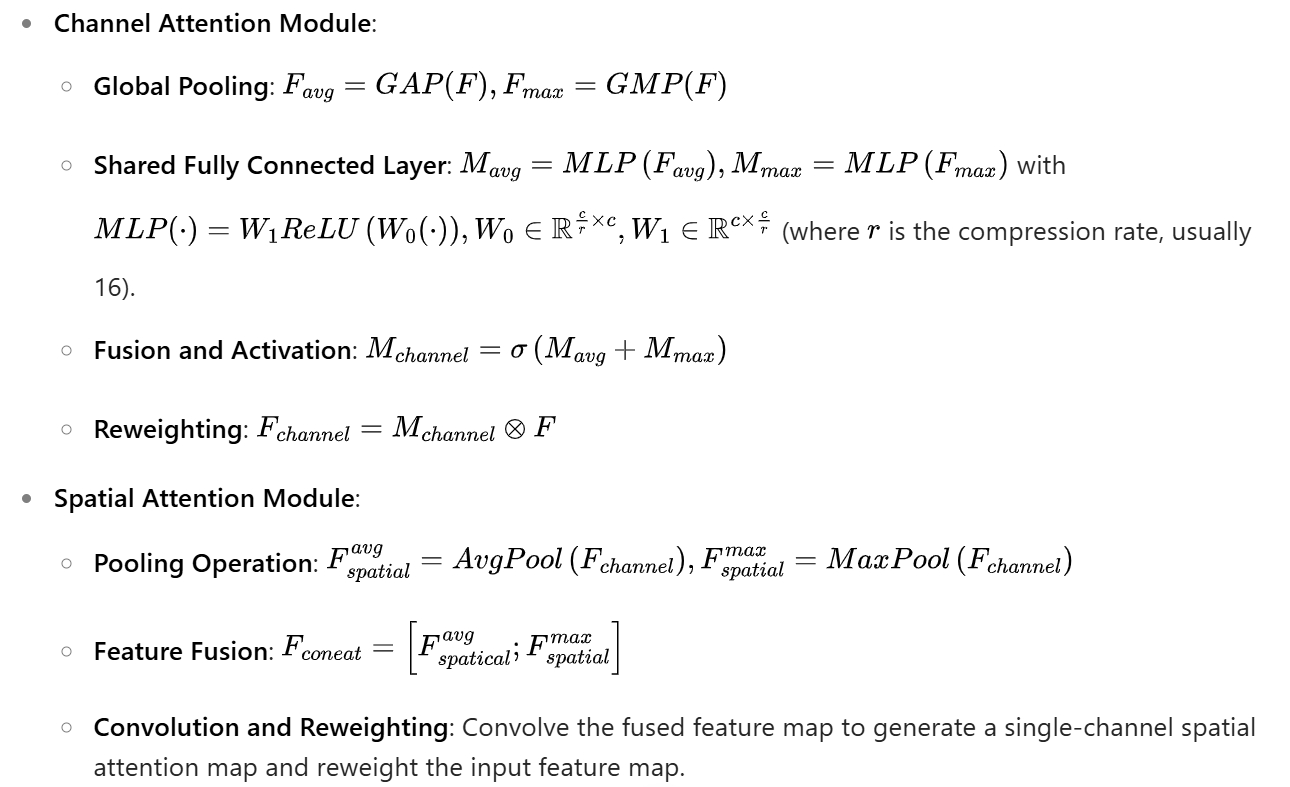

2.1 CBAM Attention Module

2.2 Deep Residual Network (ResNet) and CBAM-ResNet

- ResNet Basics: ResNet uses residual connections to solve the gradient vanishing/exploding problem. It consists of residual blocks with 3×3 convolutions, batch normalization, and ReLU activation. Skip connections add the input to the output of the block before the final ReLU.

- CBAM-ResNet Improvements:

- Channel Expansion and Optimization: Expand the original RGB channels of GADF-encoded images to 64, introduce batch normalization, and design the network to increase depth and width while maintaining computational complexity.

- CBAM Module Introduction: Insert CBAM after intermediate residual blocks to enhance feature extraction by combining channel and spatial attention mechanisms.

- Global Average Pooling and Fully Connected Layers: Use global average pooling to aggregate features and a fully connected layer for classification, reducing parameters and improving generalization.

2.3 Hybrid Whale Optimization Particle Swarm Algorithm (HWP)

- Combination of PSO and WOA: HWP combines the advantages of Particle Swarm Optimization (PSO) and Whale Optimization Algorithm (WOA) to overcome their drawbacks.

- Algorithm Steps:

- Initialization: Set initial parameters including whale and particle positions, velocities, etc.

- WOA Global Search: In the first half of the iterations (while Max_iter/2), WOA performs global search with different behaviors based on probability parameter .

- PSO Local Search: In the second half of the iterations (when Max_iter/2), PSO conducts local search, calculating particle fitness, updating positions and velocities.

- Convergence Judgment: Check if the convergence condition is met in each iteration. If so, output the optimal result; otherwise, continue until the maximum number of iterations is reached.

2.4 Arc Spiral Bevel Gear Fault Diagnosis Model

- Workflow:

- Overlapping Sampling and Noise Addition: Apply the formula for overlapping sampling, add noise to samples.

- GADF Encoding: Transform samples into 256×256 RGB images using GADF and create a labeled image dataset.

- Dataset Split: Divide the dataset into training and test sets.

- Model Optimization: Optimize the CBAM-ResNet model with HWP and save the best parameters.

- Fault Diagnosis: Classify the fault dataset using the trained model and output the diagnosis result.

3. Spiral Bevel Gearbox Fault Simulation Experiment

3.1 Fault Simulation Experiment and Dataset

- Experimental Setup: The experiment was conducted on a test rig consisting of a drive motor, torque-speed sensor, acquisition instrument, spiral bevel gearbox, planetary gearbox, base plate, magnetic powder brake, protective cover, and control system. The motor speed was 900 r/min, and the sampling frequency was 5000 Hz.

- Sensor Arrangement: ICP three-axis and single-axis acceleration sensors were used, with different channels corresponding to different axes and measurement points.

- Experimental Conditions: Seven gear conditions were tested, including normal, large gear tooth missing, large gear root crack, large gear wear, small gear tooth missing, small gear root crack, and small gear wear. Each condition was sampled for 30 seconds after the motor reached a stable state.

- Dataset Creation: A total of 7840 samples were obtained, with a training-test split of 8:2. Four datasets were constructed by adding different levels of Gaussian white noise to simulate actual noise conditions and study the impact on the model.

3.2 Comparison Experiments

3.2.1 Comparison of Different Optimization Algorithms

- Experiment Setup: Compare HWP with traditional PSO, WOA, Genetic Algorithm (GA), and Bayesian Optimization (BO) using dataset A. Record the training accuracy and convergence time.

- Results and Analysis:

| Optimization Algorithm | Running Time (s) | Accuracy (%) |

| PSO | 27636 | 99.58 |

| WOA | 45722 | 100 |

| HWP | 31384 | 100 |

| BO | 39136 | 99.87 |

| GA | 46187 | 100 |

HWP shows high accuracy and improved computational efficiency compared to WOA and GA. PSO is faster but less accurate, and BO has a moderate performance.

3.2.2 Comparison of Different Fault Diagnosis Methods

- Experiment Setup: Compare the proposed method with CooAtten-Resnet, GA-LSTM, and SeResNet. Use the best parameters from the respective literature, process the signals as described, and train on different datasets. Record the maximum test accuracy.

- Results and Analysis:

| Fault Diagnosis Method | Dataset A | Dataset B | Dataset C | Dataset D |

| CooAtten-Resnet | 100 | 98.56 | 96.98 | 94.57 |

| GA-LSTM | 99.12 | 97.56 | 94.32 | 92.31 |

| SeResNet | 99.43 | 98.10 | 95.28 | 93.57 |

| HWP-CBAM-Resnet | 100 | 100 | 97.21 | 95.38 |

The proposed method outperforms the others, especially in noisy and mixed noise datasets, demonstrating better robustness and feature extraction ability.

4. Conclusion

- HWP optimization algorithm combines the advantages of PSO and WOA, improving optimization performance with high accuracy and better convergence speed.

- GADF encoding converts time series data to images, enhancing the fault diagnosis ability of the CBAM-ResNet model.

- CBAM attention mechanism improves feature extraction and classification in complex noise, increasing model robustness.

- The signal-to-noise ratio and mixed noise affect the diagnosis accuracy, and the proposed method shows superiority in accuracy, noise resistance, convergence time, and feature extraction.