1. Introduction

Gear carburizing and quenching heat treatment is crucial for ensuring the hardness and wear resistance of gear teeth surfaces. However, this process often leads to issues such as tooth surface deformation caused by stress. Understanding the impact of carburizing and quenching on gear microstructure and deformation is essential for improving gear quality. With the development of simulation technology, it has become possible to simulate gear heat treatment to some extent. This article focuses on using simulation methods to explore the influence of material composition on the heat treatment of 22CrMo bevel gears.

2. Establishment of Material Performance Database

Two groups of material property databases were established based on the upper and lower limits of the 22CrMo composition range using material database software, as shown in Table 1.

| Grade | Chemical Composition (Mass Fraction) | |||||||

|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Mo | P | S | Al | |

| ωmin | 0.19 | 0.17 | 0.55 | 0.85 | 0.35 | 0.03 | 0.010 | 0.020 |

| ωmax | 0.25 | 0.37 | 0.90 | 1.25 | 0.45 | 0.03 | 0.030 | 0.045 |

3. Mathematical Model Establishment

3.1 Carburizing Field Model

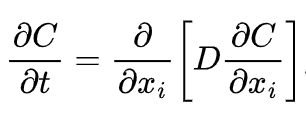

The actual carburizing process is assumed to follow Fick’s second law: .

The relationship between temperature and carbon content is given by .

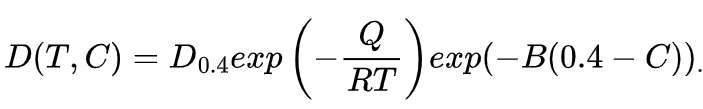

The diffusion coefficients of ωmax at different temperatures are presented in Table 2.

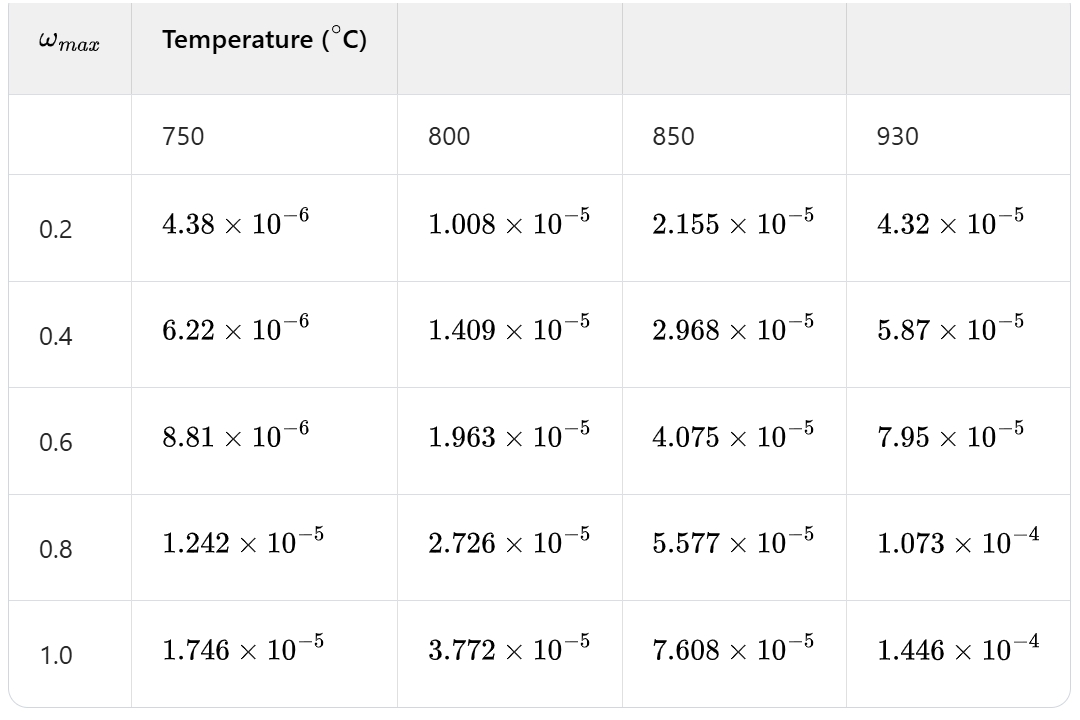

The carbon diffusion boundary condition is

3.2 Heat Conduction Model

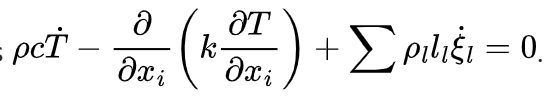

For temperature field simulation considering the influence of latent heat of phase transformation, the non-steady-state heat conduction model is .

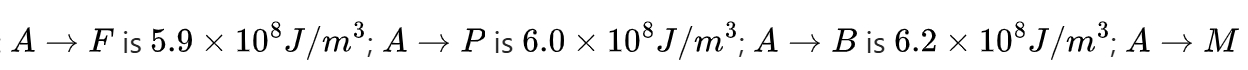

The specific heat capacity and thermal conductivity. The latent heat of phase transformation for different phases is as follows:

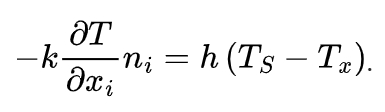

The heat transfer boundary condition between the external and the gear surface is .

3.3 Microstructure Field Transformation Model

The phase transformation models for different phases are as follows:

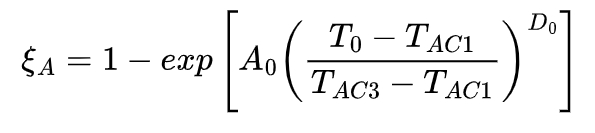

- Austenitization diffusion phase transformation in the heating stage:

- Cooling stage diffusion phase transformation:

- Martensitic transformation (non-diffusion):

3.4 Stress-Strain Model

The plastic flow stress formula in simulating the carburizing and quenching process is .

The strain rate expression is .

Some thermal physical parameters of the material.

4. Geometric Model and Process Parameters

4.1 Passive Bevel Gear Geometric Model

The analyzed gear is a passive bevel gear for a truck drive axle. Due to the large size of the part, a partial model was used for simulation.

4.2 Heat Treatment Process

The simulation process curve was determined according to the carburizing and quenching process of the passive bevel gear.

5. Results Analysis

5.1 Carbon Mass Fraction Distribution

The carbon content distribution is related to the process method. The surface carbon content affects the surface hardness, wear resistance, and fatigue strength of the gear. the carbon content changes from the surface to the core of the ωmax and ωmin gear models. After the intensive carburizing stage, the surface carbon content of both gear models is around 0.9%. After the diffusion stage, it decreases to around 0.85%. The carbon content change curves from the surface to the core of both gears are similar and relatively flat, indicating that the material composition has little effect on the carburizing of the 22CrMo bevel gear.

5.2 Phase Structure Distribution

- Martensite Volume Fraction: For the ωmax material library, the surface of the quenched bevel gear is mainly martensite, accounting for more than 90%, and the martensite volume fraction in the core is about 35%. For the ωmin material library, the surface of the quenched passive bevel gear is also mainly martensite, but there is almost no martensite in the core.

- Bainite Volume Fraction: In the ωmax passive bevel gear after quenching, there is no bainite on the surface, a very small amount near the surface, and about 65.4% in the core. In the ωmin passive bevel gear after quenching, there is bainite near the surface, and the core is all bainite.

In summary, the material composition fluctuation significantly affects the microstructure transformation during the carburizing and quenching process of the 22CrMo bevel gear.

5.3 Deformation of Bevel Gear Tooth Surface and Bottom

The main deformation problems of the passive bevel gear are the concave and convex surface deformations of the gear teeth and the internal and external warping deformations of the gear bottom, which affect the subsequent processing and assembly. the simulation results of the concave and convex surface deformations and the bottom warping deformations of the gear teeth when using and as the material libraries, respectively. Table 3 shows the deformation data. When using as the material library, the deformation degree is greater than that when using . This is mainly because the higher hardenability of leads to more complete martensitic transformation and more severe volume expansion during the transformation from austenite to martensite, resulting in greater deformation. In contrast, has lower hardenability and produces some bainite with relatively smaller volume expansion and deformation.

6. Model Verification

The actual composition of a 22CrMo passive bevel gear in a heavy-duty vehicle was tested, and the main elements affecting hardenability are close to . The surface and matrix microstructures of the measured passive bevel gear , which are consistent with the simulation results of the phase structure distribution. The P65 test results of the 22CrMo passive bevel gear are shown in Tables 5 and 6. The concave surface deformation is 63.2 m (simulation result is 59.9 m), and the convex surface deformation is 39.3 m (simulation result is 42.3 m). The error rates of the concave and convex surface deformations are 5% and 7%, respectively, with small deviations. The concave surface deformation is larger than the convex surface deformation, indicating that the simulation results are reliable and feasible.

7. Conclusions

- The material composition fluctuation of 22CrMo has little effect on the surface carburizing of the bevel gear.

- The main microstructure of the gear teeth after quenching in both material libraries is martensite. The core microstructure of the gear contains both bainite and martensite, while that of the gear is mainly bainite.

- The gear deformation analysis after quenching shows that the tooth surface deformation and bottom warping of the bevel gear with the material library are higher than those with the material library.

- The experimental verification shows that the measured results have small errors compared with the simulation results, indicating the feasibility of the model. If the composition is adjusted, it can be used as a pre-simulation for actual production.

In conclusion, the material composition fluctuation significantly affects the phase structure and deformation degree of the 22CrMo bevel gear during the carburizing and quenching process. Therefore, in actual production, the consistency of the raw material composition should be controlled as much as possible.