Abstract: The strength and service life of gears are crucial factors restricting the localization of automobiles and other high-end electromechanical equipment in China. This paper summarizes the research status and development trend of surface strengthening technology for high-strength automotive gears. By employing various surface strengthening techniques, the fatigue limit, fatigue durability, and optimal friction coefficient of gears can be significantly enhanced.

1. Introduction

Gears serve as vital components in mechanical devices for transmitting power. According to systematic investigations by the Japan Society of Mechanical Engineers on gear transmission failures across various industries, approximately 74% of gear transmission failures are caused by surface fatigue (Figure 1). With advancements in modern automobiles, new energy vehicles, military vehicles, ships, aerospace vehicles, and high-speed railway facilities, gears are required to exhibit characteristics of high strength, high speed, high efficiency, long life, lightweight, and small size. Surface strengthening technology is crucial for achieving these goals.

2. Main Failure Forms of Gears and Surface Integrity

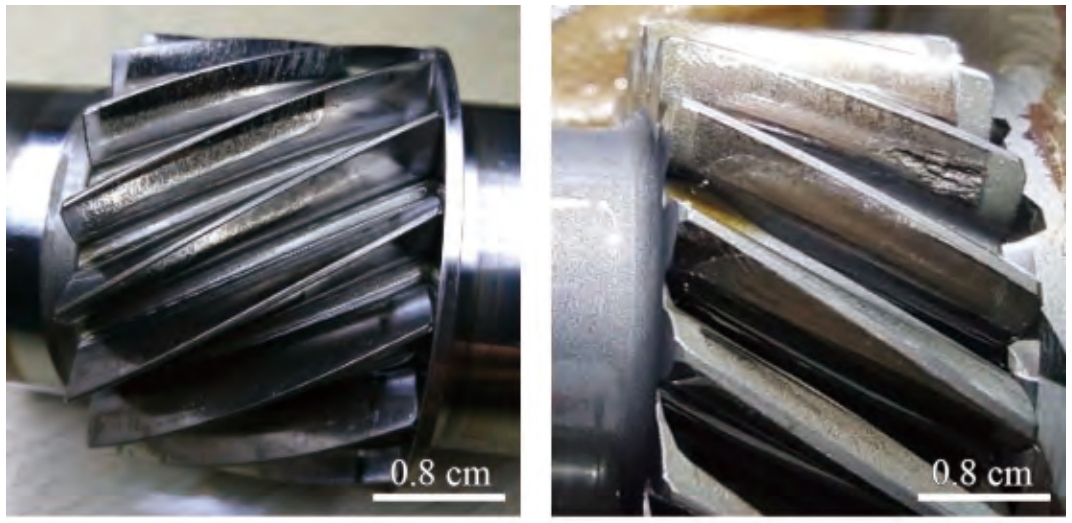

Gears typically undergo four main types of failure: tooth fracture, pitting (both macro and micro), wear, and scoring. Most failures originate from the tooth surface or tooth root. Gear surface integrity, referring to the surface condition and its associated properties after being free from damage or strengthened, includes residual stress, microhardness, surface roughness, microstructure, etc.

Table 1: Main Failure Forms of Gears

| Failure Form | Description |

|---|---|

| Tooth Fracture | Resulting from repeated concentrated stress at the tooth root |

| Macro/Micro Pitting | Surface fatigue due to contact stress |

| Wear | Gradual material removal from the tooth surface |

| Scoring | Adhesive wear caused by high friction and heat |

3. Surface Strengthening Techniques for Automotive Gears

3.1 Heat Treatment Technologies

Heat treatment technologies, such as carburizing and carbonitriding, effectively enhance gear strength and wear resistance.

Table 2: Comparison of Heat Treatment Technologies

| Technology | Description | Advantages |

|---|---|---|

| Carburizing | Increasing carbon content in the steel | Improved hardness and wear resistance |

| Carbonitriding | Simultaneous渗碳and nitriding processes | Enhanced residual austenite content, better fatigue resistance |

3.2 Shot Peening

Shot peening introduces residual compressive stress, refines microstructure, alters surface hardness, and changes surface roughness. It significantly improves gear fatigue life but requires careful control to avoid “insufficient peening” and “excessive peening.”

Table 3: Shot Peening Techniques

| Technique | Description | Advantages |

|---|---|---|

| High-Pressure Shot Peening | Using high-pressure nozzles to impact the gear surface | Significantly increases residual compressive stress |

| Composite Shot Peening | Combining large and small shot particles for peening | Enhances surface integrity, improves fatigue life |

| Emerging Techniques | Including cavitation water peening, laser peening, ultrasonic peening | Provides more precise control, larger residual compressive stress |

3.3 Surface Coating Technologies

Surface coating technologies, such as manganese phosphate conversion coating and molybdenum disulfide (MoS2) coating, further improve gear surface properties.

Table 4: Surface Coating Technologies

| Technology | Description | Advantages |

|---|---|---|

| Manganese Phosphate Coating | Reduces friction coefficient and improves anti-scuffing performance | Enhances lubrication and wear resistance |

| MoS2 Coating | Forms a soft coating on the tooth surface, reducing contact stress and friction | Improves smoothness and fatigue life |

4. Composite Surface Strengthening Techniques

Composite techniques, combining two or more surface strengthening methods, further enhance gear performance.

Table 5: Composite Surface Strengthening Techniques

| Technique | Description | Advantages |

|---|---|---|

| QPQ (Quench Polish Quench) | Combining low-temperature salt bath nitrocarburizing and oxidation | High corrosion resistance and wear resistance |

| Thermal Spraying + Shot Peening | Combining thermal spraying and shot peening for better performance | Combines high bending fatigue and contact fatigue resistance |

5. Numerical Simulation and Scientific Issues

Numerical simulation provides a platform for optimizing surface strengthening techniques. However, further research is needed in areas such as nanoscale mechanical properties, quantitative relationships between shot peening parameters and gear performance, and simulations of multiple consecutive impacts.

6. Conclusion and Future Directions

(1) Surface strengthening technology is crucial for high-strength automotive gears and holds an important position in automotive technology.

(2) Surface heat treatment, shot peening, and surface coating technologies have shown practical effects in improving the fatigue strength limit of automotive transmission gears.

(3) Future research should focus on the surface integrity and fatigue strengthening mechanisms of gears, combining interdisciplinary knowledge from thermodynamics, phase transformation thermodynamics, material mechanics, solid mechanics, tribology, and gear dynamics.