Abstract

The surface quality of spur gear directly influences their transmission accuracy and fatigue life during gear transmission. As 20CrMnTi steel is commonly used for spur gear due to its high impact load capacity and good wear resistance, the hobbing and subsequent shot peening processes can alter the surface quality of spur gear. Therefore, studying the surface quality of spur gear is of significant importance. This paper combines experimental and finite element simulation methods to investigate the hobbing and shot peening processes.

1. Introduction

The surface quality of processed spur gear has a considerable impact on the gear transmission system. Different cutting parameters in the hobbing process of spur gear cannot be ignored in terms of their influence on the surface quality. Therefore, it is necessary to study the effects of various cutting parameters on the surface roughness and hardness of spur gear during the hobbing process to improve processing accuracy and extend gear lifespan. Furthermore, this research provides spur gear with superior surface quality for actual shot peening operations, thereby enhancing the shot peening effect.

Table 1: Overview of Research Content

| Research Area | Main Content |

|---|---|

| Gear hobbing | – Experimental study on cutting power, surface roughness, and surface hardness under different cutting parameters<br>- Finite element simulation of the hobbing process |

| Shot peening | – Finite element simulation of shot peening<br>- Experimental study on the influence of shot peening parameters on surface integrity |

2. Experimental Study on Gear Hobbing

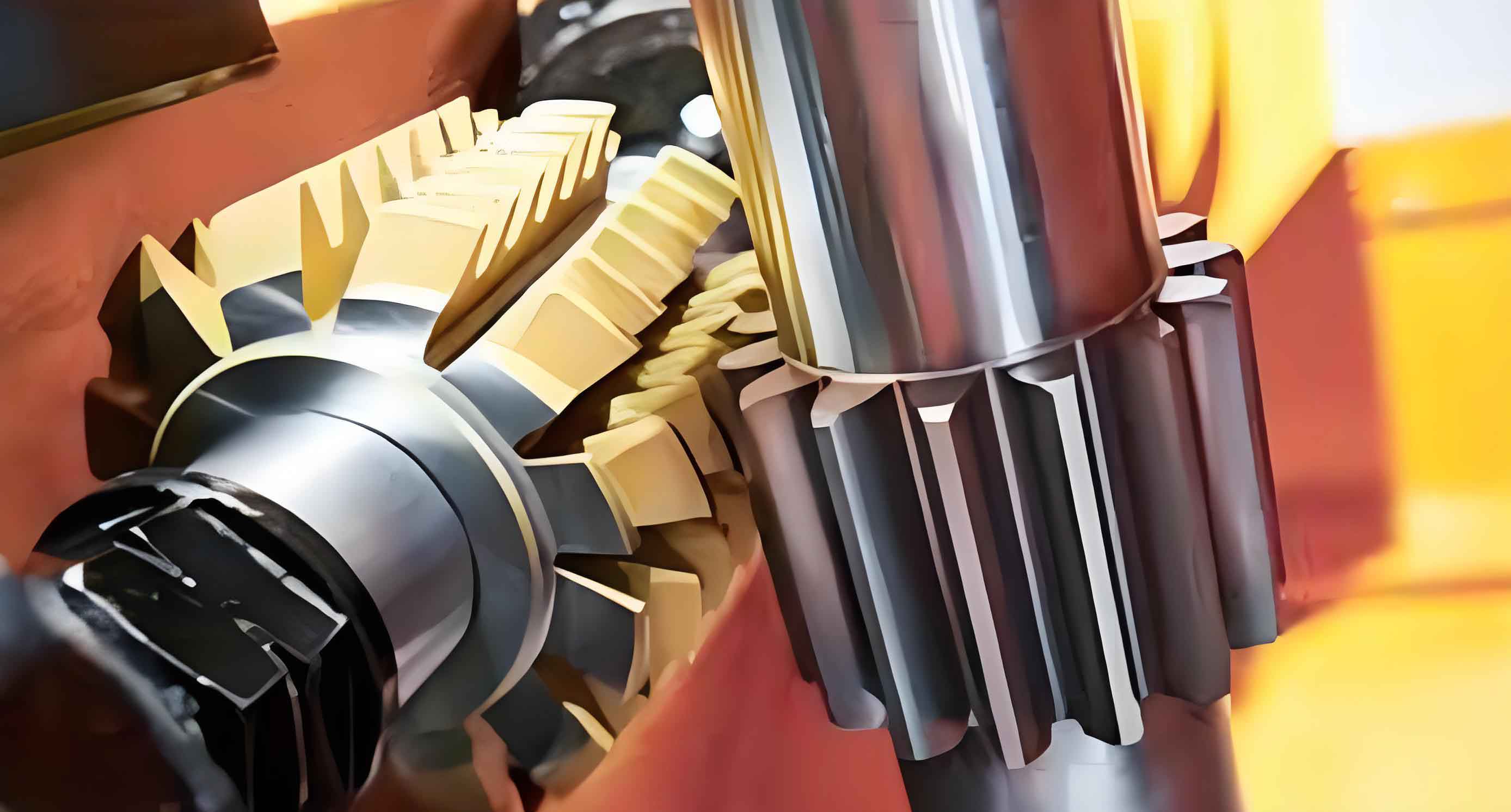

2.1 Hobbing Principle and Materials

The hobbing process involves complex movements between the hob and workpiece. 20CrMnTi steel was selected as the experimental material due to its suitable mechanical properties for gear manufacturing.

Table 2: Cutting Parameters Considered in the Experimental Study

| Cutting Parameter | Description |

|---|---|

| Hob speed | Rotational speed of the hob |

| Feed rate | Linear movement of the workpiece per revolution of the hob |

| Cutting depth | Depth of cut into the workpiece |

2.2 Measurement Methods

- Power Measurement: Using a multimeter and clamp-on ammeter to measure the voltage and current of the machine tool.

- Surface Roughness and Topography: Measured using a surface profiler (model 2302A) and a super-depth-of-field microscope.

- Hardness Measurement: Conducted using a microhardness tester.

2.3 Experimental Results

Table 3: Influence of Cutting Parameters on Hobbing Power

| Cutting Parameter | Effect on Hobbing Power |

|---|---|

| Hob speed | Increases with higher hob speed |

| Feed rate | Increases with higher feed rate |

Table 4: Influence of Cutting Parameters on Surface Roughness and Hardness

| Cutting Parameter | Effect on Surface Roughness | Effect on Surface Hardness |

|---|---|---|

| Hob speed | Decreases with higher speed | Increases with higher speed |

| Feed rate | Increases with higher rate | Decreases with higher rate |

3. Finite Element Simulation of Gear Hobbing

3.1 Model Establishment

Simplified 3D models of the hob and gear blank were created using CREO software. The finite element simulation was performed in DEFORM software.

3.2 Simulation Results

Table 5: Simulation Results of Cutting Forces and Stresses

| Cutting Parameter | Cutting Force Variation | Stress Variation |

|---|---|---|

| Hob speed | Minimal effect | Minimal effect |

| Feed rate | Increases with higher rate | Increases with higher rate |

4. Shot Peening Simulation Model

4.1 Single Shot Peen Model

A single shot peen model was established to study the energy changes during the shot peening process and the influence of shot peening speed and shot diameter on crater diameter.

Table 6: Shot Peening Simulation Parameters

| Simulation Parameter | Description |

|---|---|

| Shot speed | Velocity of the shot particles |

| Shot diameter | Diameter of the shot particles |

| Coverage rate | Percentage of surface covered |

4.2 Random Shot Peening Model

Based on the single shot peen model, random shot peening models (both single and double peening) were established using PYTHON secondary development.

5. Random Shot Peening Simulation and Experimental Study

5.1 Influence of Shot Peening Parameters

Table 7: Influence of Shot Peening Speed on Residual Stress

| Shot Peening Speed (m/s) | Residual Stress Distribution |

|---|---|

| 40 | Lower residual stress |

| 50 | Moderate residual stress |

| 60-80 | Higher residual stress |

5.2 Experimental Verification

Shot peening experiments were conducted to verify the simulation results. The surface roughness and surface topography of spur gear was measured and observed using a super-depth-of-field microscope and surface profiler.

Table 8: Comparison of Simulated and Experimental Results

| Shot Peening Speed (m/s) | Simulated Surface Roughness (Ra, μm) | Experimental Surface Roughness (Ra, μm) |

|---|---|---|

| 40 | 4.0 | 4.238 |

| 50 | 4.6 | 4.486 |

Conclusion

This paper studied the influence of different cutting parameters on the cutting power, surface roughness, and hardness of spur gear during the hobbing process. Finite element simulations were performed to analyze the cutting force and stress variations. Additionally, shot peening simulations and experiments were conducted to investigate the effects of shot peening parameters on the surface integrity of spur gear. The results provide theoretical support for optimizing the hobbing and shot peening processes of spur gear.