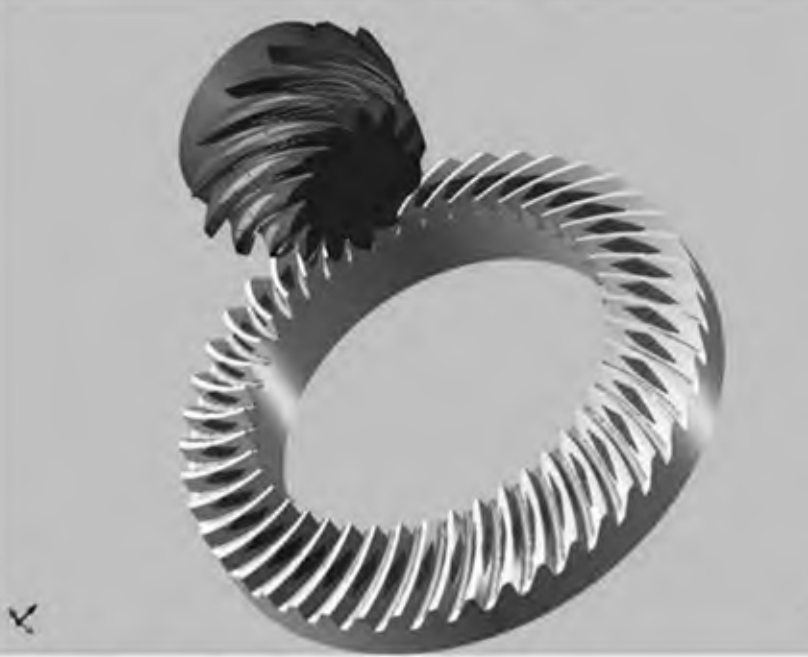

Abstract: As a special equipment for machining spiral bevel gears, the spiral bevel gear milling machine is prone to jamming issues due to backlash during the NC machining process, leading to impact and vibration phenomena, which reduce gear machining accuracy. This paper compares anti-backlash technologies and constructs a double-motor anti-backlash method for the transmission system of the spiral bevel gear milling machine based on PMAC. The anti-backlash method is tested using the dual-motor drive application system of the IPC+PMAC motion controller. The results show that this method can effectively eliminate backlash and improve the stability of the entire NC system. The use of the dual-motor servo anti-backlash method has certain reliability.

1. Introduction

In the transmission mechanism of the fully NC spiral bevel gear milling machine, to avoid jamming issues when the gear pair meshes, it is inclined to reserve a certain gap between the gear teeth, but precise control over the gap size cannot be achieved. With long-term meshing and wear of the transmission system, the backlash gradually increases, causing the linear relationship between the input of the driving gear and the output of the driven gear to become nonlinear, resulting in reduced position control accuracy and intensified impact collisions between gear teeth, which in turn causes the entire transmission system to oscillate. The machining accuracy of the milling machine and the stability of the servo system are significantly reduced.

To ensure the stability and high-precision transmission of the gear transmission system of the milling machine turntable, anti-backlash technology emerges. Anti-backlash technologies mainly include spring anti-backlash methods, mechanical anti-backlash methods, and electrical anti-backlash methods. Among them, the spring anti-backlash method is a traditional anti-backlash technology with a relatively simple structure but strict requirements on the processing accuracy of gear racks and spring compression, making it unsuitable for precision NC machine tools. Although the mechanical anti-backlash method uses a special elastic coupling to add a constant torque in advance on the coupling to generate torques in opposite directions for the meshing gears, thereby eliminating the backlash generated during transmission, its structure is complex, requiring special couplings and preload tools, and the stability of transmission accuracy is low.

The electrical anti-backlash technology, typically represented by dual-motor anti-backlash, can effectively improve the defects of traditional anti-backlash technologies, maintaining good stability of transmission accuracy while eliminating backlash, and thus gradually replacing spring anti-backlash methods and mechanical anti-backlash methods as the mainstream anti-backlash technology. The dual-motor anti-backlash device includes two electric motors, two reducers, two gears, and a rack. Two servo motors with the same drive parameters are connected to the reducers, which are then connected to their respective drive gears. The two sets of gears and racks that mesh with each other jointly bear the load movement.

| Component | Description |

|---|---|

| Electric Motor | Provides torque to drive the gears |

| Reducer | Reduces the speed and increases the torque |

| Gear & Rack | Transmits motion and load |

| Torque Compensator | Distributes torque to achieve anti-backlash |

2. Analysis of the Motion Process of the Dual-motor Anti-backlash Mechanism of the Milling Machine

2.1 Analysis of the Starting Process

The starting process of the dual-motor anti-backlash mechanism of the milling machine is divided into four stages, with the output torques of the driving motor and driven motor interacting with the bias torque at each stage to achieve the purpose of eliminating backlash.

Table 1. Stages of the Starting Process

| Stage | Speed Command (ω) | Torque of Driving Motor (M1) | Torque of Driven Motor (M2) | Bias Torque Distribution | Movement of Rack |

|---|---|---|---|---|---|

| 1 | 0 | -M (bias) | M (bias) | Equal and opposite | Stationary |

| 2 | >0 | Md1 > Md2 | Md2 (opposite direction) | Md = Md1 – Md2 (positive) | Moves in positive |

| 3 | Increasing but < rated | Md1 increases | Md2 = 0 (disengaged) | Md = Md1 | Continues moving + |

| 4 | Rated | Positive | Positive | Bias torque withdrawn | Common load bearing |

2.2 Analysis of the Reversing Process

The reversing process begins with the speed command gradually decreasing from the rated value. The torque compensator redistributes the bias torque on the driving motor and driven motor, superimposing it with their respective output torques and ensuring the superimposed torques remain in the positive direction, so that the driving gear and driven gear remain meshed on the same side of the rack to drive it in the forward direction. As the speed command continues to decrease, the superimposed torque of the driven motor gradually decreases until it reaches zero, causing the driven gear to disengage and quickly cross the backlash to re-engage on a different side of the rack.

2.3 Analysis of the Starting and Reversing Processes

Through the analysis of the starting and reversing processes of the dual-motor anti-backlash mechanism of the milling machine, it can be seen that during these processes, the bias torque distributed by the torque compensator, superimposed with the output torques of the driving motor and driven motor, acts on the driving gear and driven gear. The purpose is to ensure that at least one set of gears and racks is meshed during transmission, preventing the rack from moving freely in the backlash, thereby eliminating the backlash issue.

3. Experimental Setup and Result Analysis of Dual-motor Anti-backlash Technology

3.1 Experimental Platform Setup

In selecting the hardware for the experimental platform, an industrial PC is chosen as the upper computer and PMAC as the lower computer, connected through a controller (CK3E). The industrial PC communicates with the controller via information transmission and human-computer interaction, while the controller serves as the lower computer’s controller. The configuration of IPC+CK3E enables the dual-motor drive application system to have two relatively independent CPUs, resulting in high operational efficiency and fast response speed. High-performance servo drivers (CDHD) and PRHD2 DC servo motors are used, characterized by excellent servo performance, high power density, and simple debugging, providing easy and quick debugging and high economic applicability.

Table 2. Experimental Platform Components

| Component | Description |

|---|---|

| Upper Computer (IPC) | Controls and monitors the experimental system |

| Lower Computer (PMAC) | Manages and processes motion control commands |

| Controller (CK3E) | Facilitates communication between IPC and PMAC |

| Servo Driver (CDHD) | Powers and controls the DC servo motors |

| DC Servo Motor (PRHD2) | Provides the torque for the dual-motor system |

The experimental results demonstrate that the proposed dual-motor anti-backlash method effectively eliminates backlash and significantly enhances the stability of the entire NC system, confirming the reliability of the dual-motor servo anti-backlash approach.

Conclusion

The research presented in this paper introduces a dual-motor anti-backlash method for the transmission system of spiral bevel gear milling machines based on PMAC. Through detailed analysis and experimental validation, it is shown that this method can effectively eliminate backlash, improve system stability, and maintain high transmission accuracy, addressing the issues caused by backlash in spiral bevel gear milling machines.