Abstract: Existing gear hobbing simulation methods struggle to adhere to actual processing parameters and lack effective tooth surface accuracy measurements for the obtained simulation models, thereby failing to provide valuable guidance for practical gear hobbing operations. To address this, a high-precision gear hobbing simulation and accuracy verification method is proposed. Based on the CATIA design platform, this method employs commands such as translation, rotation, and Boolean operations, combined with secondary development capabilities, to create a preliminary tooth groove model incorporating both main and generative motion characteristics. The preliminary tooth groove model is then used to simulate the vertical feed motion cutting with the tooth blank, completing a high-precision gear hobbing simulation. By establishing a standard tooth surface point set to measure the accuracy of the simulation model tooth surface, the error distribution of the simulation tooth surface is obtained. The highest tooth surface accuracy error in the resulting simulation model is below 1 μm, verifying the correctness of the gear hobbing simulation method and the accuracy of the simulation model.

Keywords: gear hobbing, simulation, accuracy verification, CATIA, tooth surface error

1. Introduction

With the development of modern computer technology, significant advancements have been made in the field of gear hobbing simulation in China. Various research efforts have focused on different software platforms and applicable methods, yet few have integrated gear hobbing simulation with actual processing parameters. Additionally, in-depth exploration of simulation model accuracy verification remains insufficient. Consequently, existing gear hobbing simulation methods cannot provide precise and effective guidance for practical processing. This paper proposes a high-precision gear hobbing simulation and accuracy verification method to address these issues.

2. Gear Hobbing Simulation Based on CATIA

2.1 Principle of Gear Hobbing

Gear hobbing involves processing gears using the generative method, which can be visualized as a gear engaging with a rack without backlash. During gear hobbing, the main motion is the rotation of the hob around its own axis, while the generative motion ensures that the tooth blank强制性 maintains the engagement relationship between the gear and the rack. The vertical feed motion is a linear motion in which the hob moves down the tooth blank axis to cut the tooth shape across the tooth width.

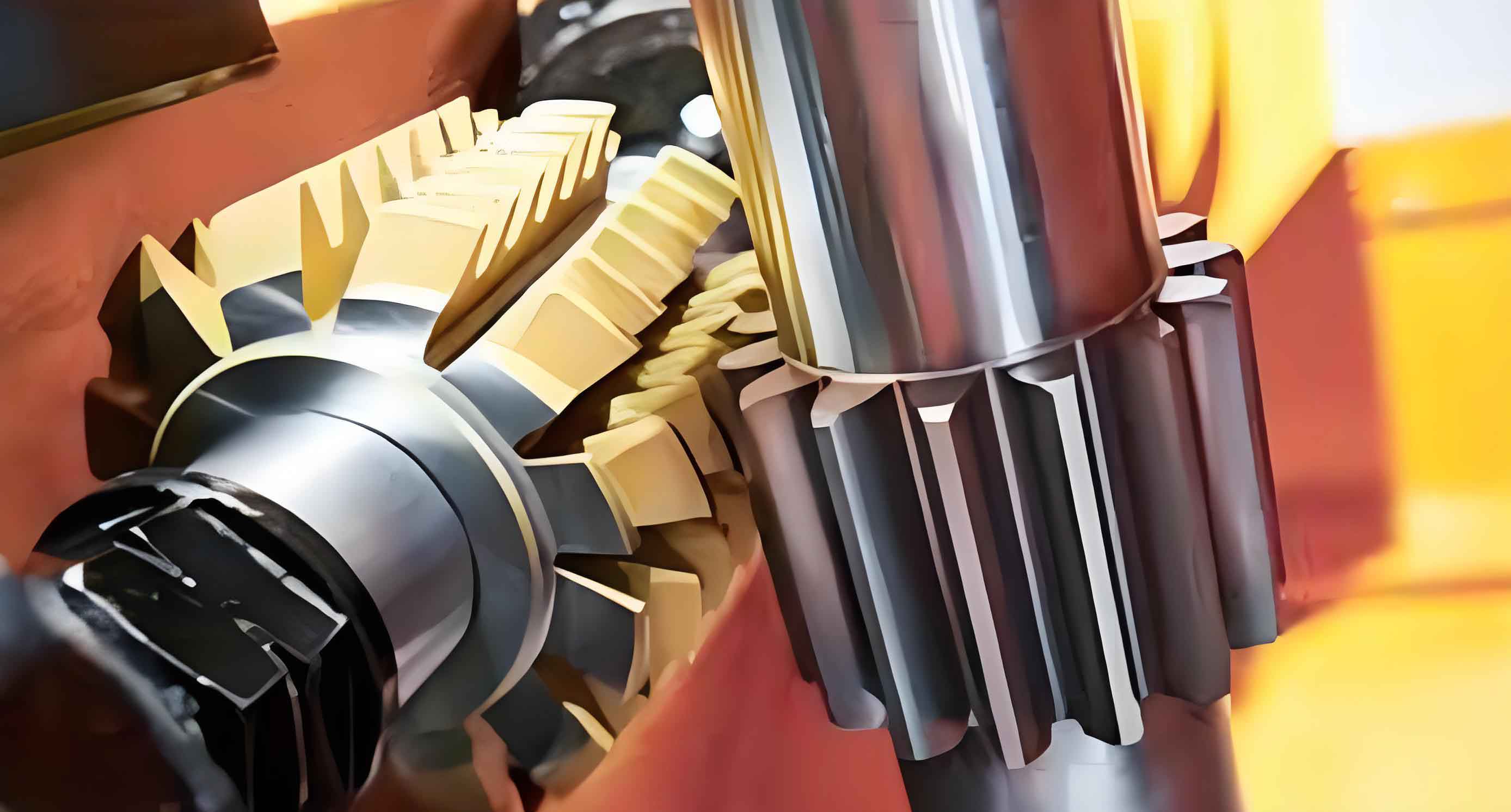

2.2 Hob and Tooth Blank Model Establishment

To ensure smooth cutting, chip removal, and heat dissipation during gear hobbing, relief grooves are milled on the hob. The simulation in this paper uses Boolean subtraction operations in CATIA to simulate the cutting of the tooth blank by the hob, so there is no need to consider the impact of chip removal and heat dissipation in hob design.

2.3 Gear Hobbing Simulation Process

The gear hobbing simulation process involves multiple steps:

- Model Creation: Establish the tooth blank and hob models in the CATIA part design environment.

- Assembly: Assemble the hob to the midpoint of the tooth blank tooth thickness.

- Main and Generative Motion Simulation: Convert the assembly model to a part model and simulate the main and generative motions. Use Boolean subtraction operations to remove the intersecting material from the tooth blank after each simulation segment.

- Preliminary Tooth Groove Extraction: Once a complete tooth shape envelope is obtained, extract the preliminary tooth groove model, which contains all critical processing features except for the vertical feed motion.

- Vertical Feed Motion Simulation: Use the preliminary tooth groove to simulate the vertical feed motion. After each vertical feed motion and additional rotation, perform Boolean subtraction operations to envelope the current tooth shape.

- Complete Tooth Groove Extraction and Array: Once a complete tooth groove is cut across the entire tooth width, extract it and array it to perform Boolean subtraction with the tooth blank to obtain the final gear hobbing simulation model.

Table 1. Required Processing Gear Parameters

| Parameter | Value |

|---|---|

| Number of Teeth | 20 |

| Helix Angle / (°) | 20 |

| Normal Modulus / mm | 2 |

| Head Clearance Coefficient | 0.25 |

| Spiral Direction | Right |

| Modification Coefficient | – |

| Normal Pressure Angle / (°) | 20 |

| Addendum Height Coefficient | 1 |

3. Accuracy Verification and Analysis of the Simulation Model

3.1 Accuracy Verification of the Simulation Tooth Surface

After obtaining the simulation model through gear hobbing simulation, accuracy verification of the simulation model tooth surface is necessary to validate the correctness of the simulation method and the accuracy of the obtained simulation model.

To verify the accuracy of the helical gear simulation model, a theoretical tooth profile coordinate equation is established based on the tooth blank parameters and the knowledge engineering function in CATIA. A set of theoretical involutes is created by assigning different values to the involute angle variable t.

To meet the accuracy measurement requirements of the simulation model in the entire tooth thickness direction, a set of datum planes is established equidistantly along the tooth thickness direction of the tooth blank, and involutes are established on each datum plane. A set of equidistant points is then established on one side of the involute set to form the required single tooth surface point set for measurement.

3.2 Accuracy Analysis of the Simulation Model

The main feed parameters in gear hobbing simulation are the circumferential feed parameter Δθ and the vertical feed rate h. Δθ is determined by the number of hob teeth. To analyze the influence of the vertical feed rate h on the maximum tooth surface error, experiments are conducted using a 12-tooth hob as a benchmark and a 24-tooth hob for comparison.

Based on the recommended vertical feed rates provided by German tool manufacturers, different vertical feed rates h are selected for simulation.

Conclusion

This paper proposes a high-precision gear hobbing simulation and accuracy verification method based on the CATIA design platform. By simulating the gear hobbing process, a preliminary tooth groove model is extracted and used to simulate the vertical feed motion, completing a high-precision gear hobbing simulation. The accuracy of the simulation model tooth surface is measured by establishing a standard tooth surface point set, obtaining the error distribution of the simulation tooth surface. The highest tooth surface accuracy error in the obtained simulation model is below 1 μm, verifying the correctness of the gear hobbing simulation method and the accuracy of the simulation model. This method can also be applied to shaping and grinding processes, providing solutions for high-precision simulation and accuracy verification of these processes.