Abstract: The tool spindle system of a spiral gear milling machine is prone to chatter during machining, affecting the quality of the workpiece. To address this issue, an equivalent dynamic model of the tool spindle system is constructed based on the lumped mass method. The stiffness matrix of the spindle rotor is obtained using Timoshenko beam theory. By analyzing the mechanics of the tapered roller bearings, formulas for calculating the axial and radial stiffness of the bearings under axial preload are developed. The dynamic model of the tool spindle system constructed using numerical analysis is validated through hammer excitation experiments. The comparison results indicate that the constructed dynamic model can effectively reflect the dynamic characteristics of the tool spindle system.

1. Introduction

The dynamic characteristics of the spindle-bearing system directly relate to the machining accuracy, stability, and reliability of CNC machines. Precision rotating machinery requires dynamic design at the initial stage of design, and establishing a reasonable dynamic model based on mechanical components is fundamental to dynamic design. When milling spiral gears with a CNC spiral gear milling machine, the tool follows a complex spatial curve. If the dynamic performance does not meet the requirements, chatter may occur, affecting the machining quality of the milled workpiece. The dynamics of rotating machinery has always been a research focus in the field of dynamics. A stable and reliable dynamic model of rotating machinery can not only directly improve design efficiency and optimize traditional mechanical design schemes but also provide support for improving the comprehensive performance indicators of existing machinery.

2. Literature Review

Scholars have conducted numerous studies on the dynamics of beams and rolling bearings and have conducted some research on the contact dynamics of spindle system interfaces. However, there is a lack of research on spindle-bearing systems, particularly on the dynamic analysis of tool spindle systems in spiral gear milling machines.

3. Dynamic Model Construction of the Tool Spindle System

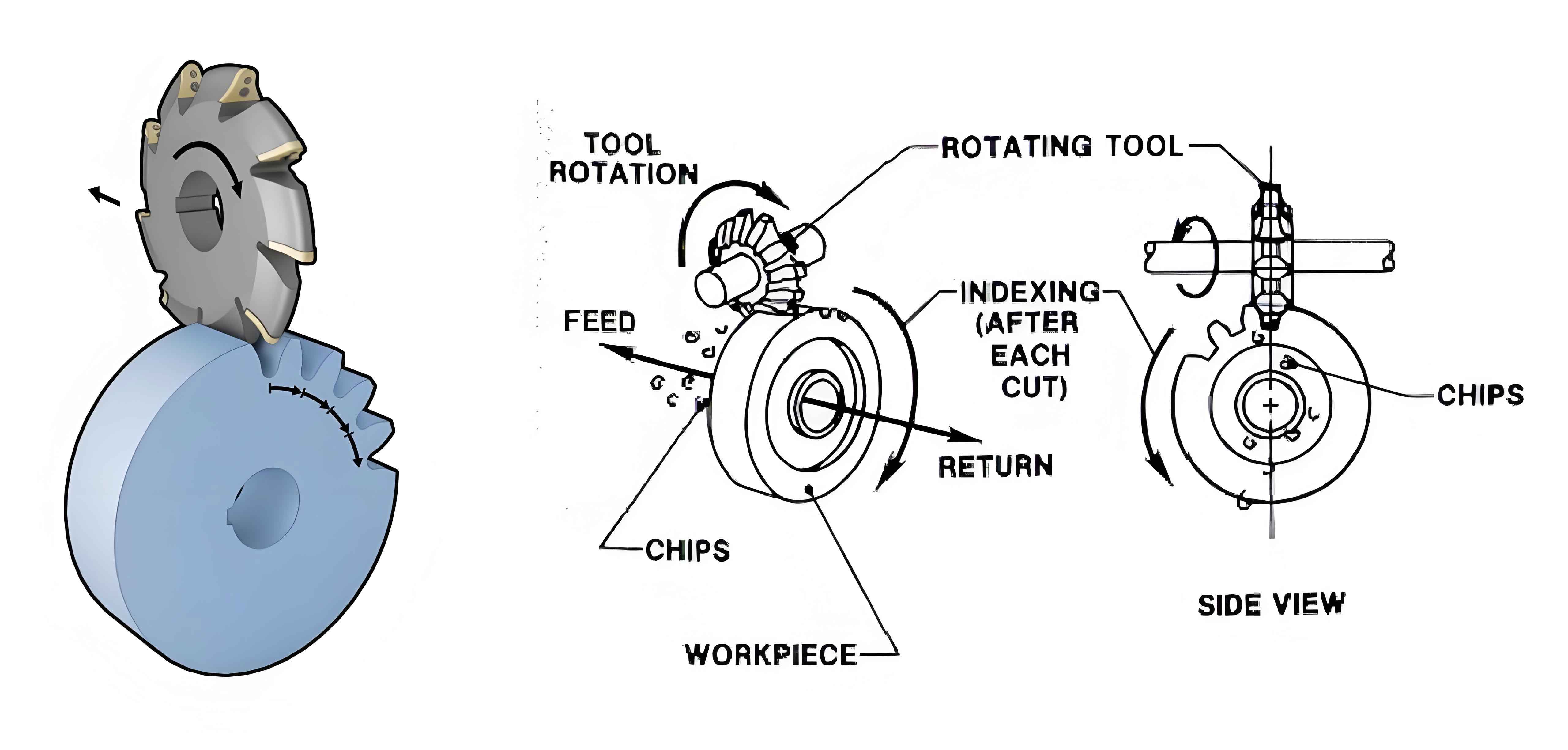

The tool spindle system is a crucial component of a CNC spiral gear milling machine, and its operational stability directly relates to the machining accuracy of the milling machine. Establishing a dynamic analysis model for the tool spindle system of the milling machine can help analyze and improve its dynamic characteristics.

3.1 System Overview

The tool spindle system of a domestic CNC spiral gear milling machine consists of a spindle, tapered roller bearings, a torque motor, a tool disc body (including the tool disc and the flange that carries it), and a connecting sleeve.

3.2 Dynamic Model Construction

Based on the mechanical structure of the tool spindle system, a particle system dynamics model of the tool spindle system is established, focusing on bearings, spindles, tool discs, and torque motors. The following assumptions are made when constructing the simplified dynamic model of the tool spindle system:

- The tool disc, flange, torque motor rotor, and spindle are rigidly connected.

- The outer ring of the tapered roller bearing is assumed to be stationary, and the inner ring is rigidly connected to the spindle with a large stiffness due to interference fit.

3.3 System Discretization

The equivalent masses at the right and left tapered roller bearings, mb1 and mb2, include the masses at the bearings, the connecting sleeve, and the torque motor equivalent to the bearings.

3.4 Dynamic Equation

The total potential energy of the tool spindle system is given by:

Where kb1 and kb2 are the radial stiffnesses at the left and right tapered roller bearings, respectively, and kz is the axial stiffness of the tool spindle.

According to modal analysis theory in mechanical dynamics, the undamped dynamic equation of the tool spindle system is established as:

Where M is the mass matrix, K is the stiffness matrix, and F(t) is the load matrix.

4. Dynamic Analysis of Tapered Roller Bearings

Tapered roller bearings belong to a typical multi-body rigid-flexible coupling system. Their flexible characteristics should be considered during high-speed operation, but under low-speed, heavy-load conditions, they can generally be treated as rigid bodies for equivalent processing.

To establish the dynamic model of the tapered roller bearing and to ensure the convergence of the calculation results, the following assumptions are generally made:

- The outer ring of the tapered roller bearing is stationary.

- The inner ring is rigidly connected to the shaft and can rotate at any angular velocity.

- The contact stress distribution between the tapered roller and the inner and outer rings conforms to Hertz contact theory.

- Under load, elastic displacement occurs in the rollers and inner ring of the tapered roller bearing, while the outer ring remains fixed.

Based on the mechanical structure of the tapered roller bearing and the aforementioned assumptions, the mechanical analysis diagram of the rollers of the tapered roller bearing is obtained.

5. Experimental Verification

Numerical analysis methods are used to solve the differential equations of the dynamic model of the tool spindle-bearing system. Experimental methods are commonly used to verify whether the constructed digital model conforms to engineering practice. In this paper, the Siemens LMS Test.lab experimental equipment is used. The tool spindle system is excited at a fixed point with a hammer (hammer impact force of 700-1000 N), and a piezoelectric acceleration sensor is used to collect vibration signals from the spindle system, with an initial preload of 3000 N.

The acceleration sensors are primarily placed to measure vibrations in the X, Y, and Z directions at the two tapered roller bearings of the spindle. The working speed of the tool spindle system of the CNC spiral gear milling machine is low, and its mass is large. Therefore, the first six natural frequencies of the tool spindle system are extracted from both the numerical calculation results and the vibration experimental data analysis results. Based on the vibration signals collected from the experiment, the relative errors between the two are calculated.

The preload is adjusted appropriately and increased to 6500 N (in accordance with the technical guidance in the bearing engineering manual, which meets the preload requirements during bearing installation). The first five natural frequencies of the spindle system are then calculated based on the spindle system dynamics model, as shown in Table 1.

Table 1: Comparative Analysis of Numerical Calculation Results and Experimental Results

| Preload (N) | Order of Natural Frequency | Numerical Calculation (Hz) | Experimental Measurement (Hz) | Relative Error (%) |

|---|---|---|---|---|

| 3000 | 1 | X | X | Y |

| 2 | X | X | Y | |

| 3 | X | X | Y | |

| 4 | X | X | Y | |

| 5 | X | X | Y | |

| 6 | X | X | Y | |

| 6500 | 1 | A | B | C |

| 2 | A | B | C | |

| 3 | A | B | C | |

| 4 | A | B | C | |

| 5 | A | B | C |

(Note: Replace X, Y, A, B, C with actual numerical values from the study)

When the preload is increased to 6500 N, the first five vibration frequencies of the tool spindle system increase to some extent, with the first three vibration frequencies showing a more significant increase. This is beneficial for the spindle system to avoid accumulating significant vibration energy during operation, preventing resonance and adverse effects on the overall machine performance.

6. Conclusion

Based on the mechanical structure of the tool spindle system, the tool spindle system is equivalently processed using the lumped mass method, and an equivalent dynamic model of the tool spindle system is established. The undamped dynamic equation of the tool spindle system is derived from the equivalent dynamic model, and the dynamic differential equation of the tool spindle system is constructed using the energy method and Lagrange’s operator, yielding the mass matrix and stiffness matrix of the tool spindle system.