Abstract:

The issue of uneven grinding allowance and surface hardness in the tooth section of a sun gear. By analyzing the data on tooth variations and conducting process experiments, we introduce tooth profile modification during gear hobbing to compensate for distortions resulting from the heat treatment process. This method enhances product quality and extends product service life.

1. Introduction

Our company encountered quality issues when producing sun gears for wind turbine gearboxes in small batches. Due to heat treatment deformation, the teeth exhibited minute steps at the tooth root on both ends and black spots in the middle of the tooth width due to insufficient allowance. Consequently, the common normal line exceeded the tolerance limits. Some workpieces were scrapped due to excessive deformation and insufficient allowance in the middle of the tooth width. This quality issue significantly reduced product qualification rates, impacted timely product delivery, and increased production costs. Analysis revealed that this deformation caused uneven grinding allowance in the tooth section, leading to uneven effective hardened layer depth and hardness on the tooth surface after grinding. This, in turn, reduced the contact strength and load capacity of the gear and affected the fatigue strength of the tooth root, ultimately lowering the service life of the gear.

Previous research by Li Chunling et al. [1] focused on the reliability and failure rate of sun gears in wind turbine gearboxes based on dynamic reliability models for mechanical components under random loads. Xu Hui et al. [2] explored sun gear heat treatment processes and optimized equipment and heat treatment gas sources. Gu Xiaoming et al. [3] reduced bending deformation of sun gears by changing clamping methods and pre-heat treatment structures. However, none of these studies addressed the method of compensating for heat treatment distortion through gear hobbing modification. Taking a certain type of sun gear shaft as an example, this paper investigates the influence of gear hobbing modification on heat treatment deformation to ultimately improve product quality and service life.

2. Pre-improvement Process and Deformation

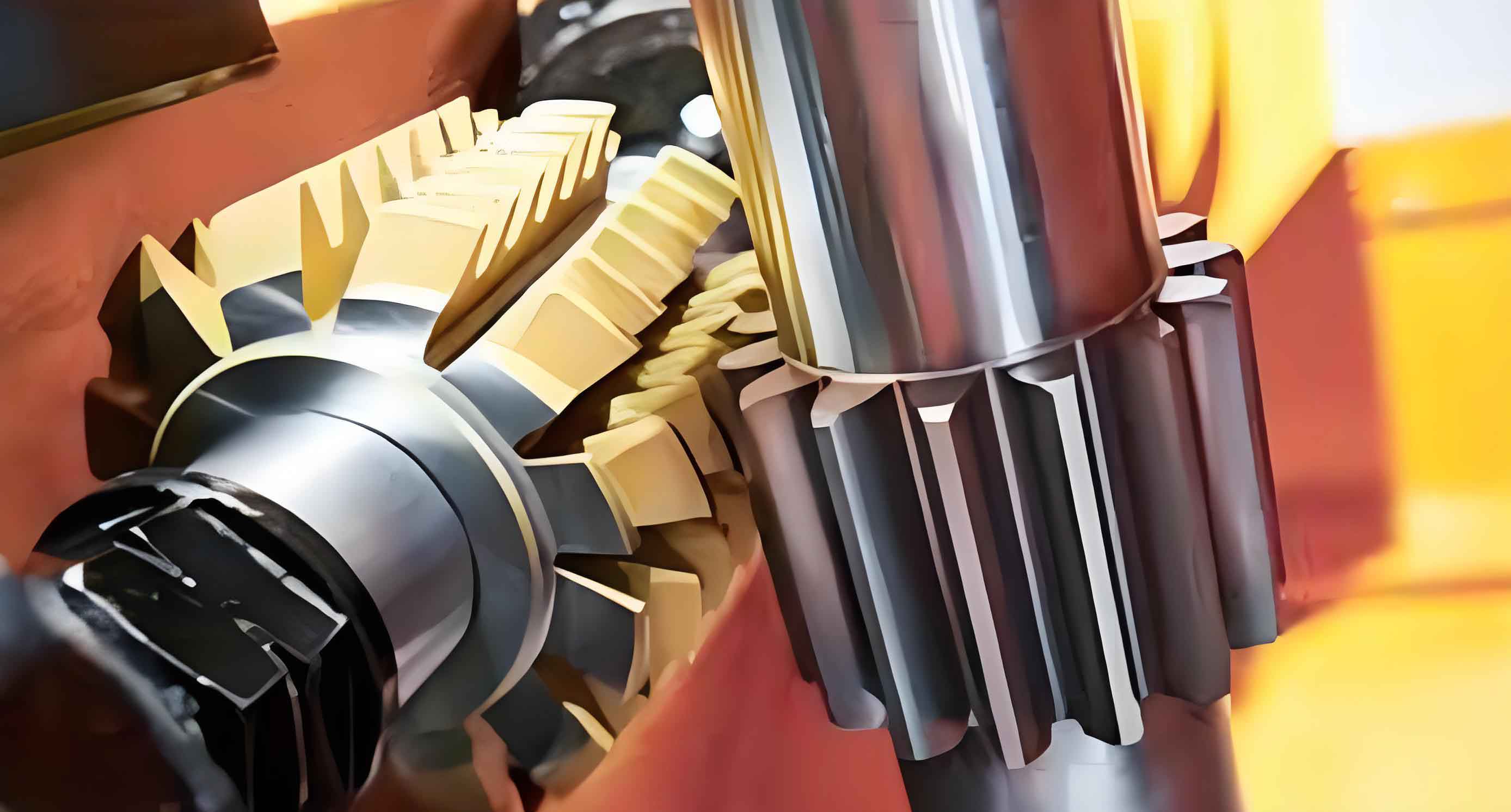

The structure of the sun gear in question is shown in Figure 1. The material is 18CrNiMo7-6 steel, with a module of mn = 15mm, tooth number Z = 24, pressure angle α = 25°, tooth width B = 388mm, and a common normal line W4 ranging from 163.468 to 163.546mm. The tooth section requires carburizing and quenching to achieve a tooth surface hardness of 58-62HRC and an effective hardened layer depth of 2.5-3.0mm.

Figure 1: Sun Gear Structure Diagram

The production process route includes: forging → post-forging heat treatment → rough turning → ultrasonic inspection → semi-finishing turning → gear hobbing → heat treatment → finishing turning → ultrasonic inspection → deep hole drilling → outer circle grinding → spline rolling → tooth grinding → inspection. As an axial part, the gear hobbing process sets the common normal line W4 at 164.16mm, with an allowance ΔW = 0.66mm, and other gear hobbing parameters are executed according to the original design. A convex corner grinding hob is selected to avoid grinding steps after tooth grinding. The heat treatment process requires a tooth surface hardness of 58-62HRC and a carburized layer depth of 3.2-3.7mm.

After processing according to this process, post-heat treatment common normal line measurements were conducted (measuring one circumference every 15mm along the tooth width direction, with three evenly distributed measurement points per circumference). The data is summarized in Table 1.

Table 1: Actual Measurement Values of Common Normal Line After Heat Treatment Before Improvement (Unit: mm)

| Measurement Position | Circumferential Point 1 | Circumferential Point 2 | Circumferential Point 3 |

|---|---|---|---|

| 15 (Position ①) | 164.35 | 164.34 | 164.35 |

| 65 (Position ②) | 164.20 | 164.22 | 164.23 |

| … | … | … | … |

| 365 (Position ⑧) | 164.14 | 164.11 | 164.10 |

The sun gear expands significantly within the first 65mm from the shaft end (Position ②) and contracts in other areas after heat treatment. Especially at the upper end of the tooth section (Position ①, 15mm from the tooth end), the expansion is evident, with the average common normal line value increasing by 0.19mm compared to before heat treatment. In the middle and lower sections (Position ⑤, 215mm from the tooth end), the average common normal line value decreases by 0.29mm compared to before heat treatment, with a unilateral contraction of about 0.15mm, creating a concave center. The difference between the highest and lowest common normal line values reaches 0.51mm.

Pre-tooth grinding alignment allowance measurements are shown in Table 2. The deformation trend derived from the measurement data matches the tooth surface condition after tooth grinding. A grinding step appears at the tooth root within about 65mm from the shaft end to Position ②. From Position ② to Position ⑤, the tooth surface allowance gradually decreases, with the smallest allowance at Position ⑤, leaving black spots on the tooth surface that cannot be ground out.

Table 2: Tooth Grinding Alignment Allowance Before Improvement (Unit: 10μm)

| Alignment Position | 1 | 2 | 3 | 4 | 4-3-3 (Tooth Left, Tooth Right, Tooth Left, Tooth Right) |

|---|---|---|---|---|---|

| Upper Inner | 40 | 30 | 27 | 56 | -3, -3 |

| … | … | … | … | … | … |

| Lower Outer | 25 | 22 | 20 | 28 | -5, -8 |

3. Causes and Impacts of Heat Treatment Deformation

Heat treatment deformation of workpieces is primarily caused by heat treatment stresses. Factors such as workpiece structure, raw material quality, pre-heat treatment processing state, workpiece weight, and improper supporting or clamping during heating and cooling in the furnace can also cause deformation.

3.1 Main Causes of Heat Treatment Deformation

From the typical workpiece shape and size change models under thermal stress and structural stress summarized in literature [4], the following can be deduced:

- Since the sun gear shaft is a rod-like component with a relatively small control section, structural stress dominates, leading to saddle-shaped deformation. According to the deformation model, the middle of the tooth width contracts, while both ends slightly expand.

- The reason for slight expansion at both ends is that the end has a smaller thermal capacity and can produce more martensite structure compared to the middle of the tooth width. Due to the larger specific volume of martensite, both ends expand relative to the middle of the tooth width.

3.2 Main Impacts

- Uneven carburized layer depth after tooth grinding. When grinding to the lowest point, the carburized layer depth at both ends is 0.26mm shallower than in the middle.

- Uneven tooth surface hardness. According to tooth grinding allowance distribution records, the grinding amount in the middle pitch circle of the tooth width is 0.1mm, while individual points at the ends have an allowance of 0.6mm. The hardness gradient diagram (Figure 2) shows that the hardness at 0.1mm is 680HV (59.2HRC), and the hardness at 0.6mm is 57HRC, which does not meet requirements.

Figure 2: Hardness Gradient Diagram

4. Improvement Plan and Analysis

4.1 Improvement Plan

- Add a process shaft head to the end face of the sun gear teeth to increase the end thermal capacity and reduce expansion.

- Increase the common normal line allowance before heat treatment to ensure sufficient grinding allowance for all parts.

- Utilize numerical control gear hobbing machines to add a tooth profile modification (bulge shape) during gear hobbing to offset heat treatment deformation using the principle of reverse deformation.

4.2 Plan Analysis

- Plan 1: Adding a process head at the shaft end can correspondingly reduce heat treatment deformation but increases raw material procurement costs, requires subsequent removal of the process head, increases production costs, and reduces production efficiency.

- Plan 2: Increasing the grinding allowance is a commonly used process method in the industry to ensure that the smallest allowance area can be ground out. However, this method exacerbates issues such as tooth root steps, uneven carburized layer, and uneven hardness.

- Plan 3: Utilizes the advanced functions of existing machines. Adding a tooth profile modification (bulge shape) during gear hobbing to offset heat treatment deformation does not affect gear hobbing production efficiency or costs.