Introduction

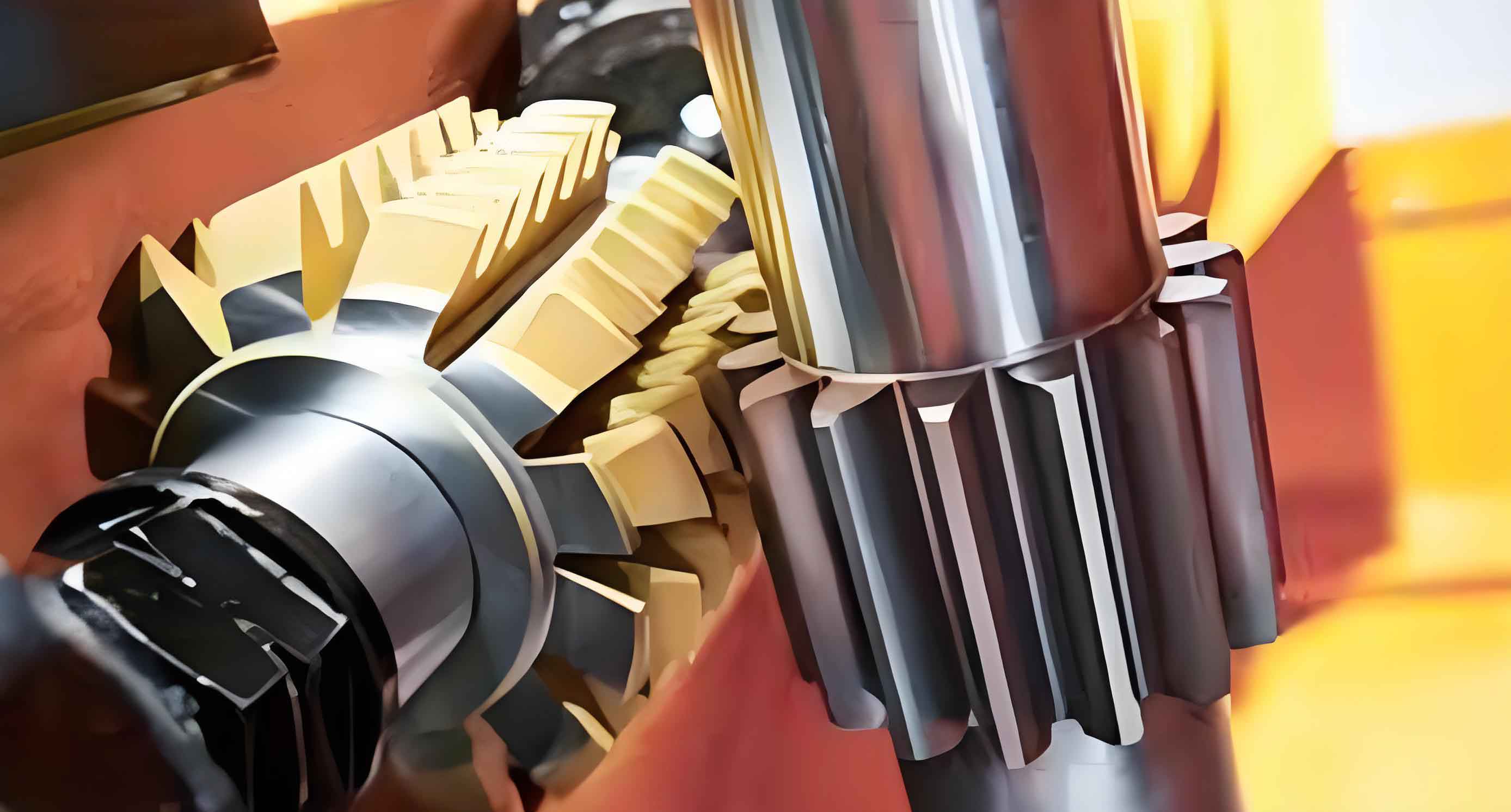

Gear hobbing is a highly efficient and precise method for manufacturing both cylindrical and non-circular gears. With applications spanning automotive, robotics, and industrial machinery, gear hobbing has become integral to high-performance gear systems. Non-circular gears, known for their ability to transfer nonlinear motion, pose unique challenges due to cutting force fluctuations during manufacturing.

This article explores the dynamics of gear hobbing in non-circular gears, emphasizing cutting force fluctuations, suppression techniques, and the role of advanced machining models. It consolidates theoretical insights, practical methodologies, and experimental data into an informative guide.

1. Principles of Non-Circular Gear Hobbing

Non-circular gear hobbing can be understood as the meshing process between a worm and a non-circular gear. Unlike cylindrical gears, non-circular gears require synchronized multi-axis movement during hobbing. This synchronization ensures the accurate replication of the gear profile as defined by its pitch curve.

Key Features

- Axis Synchronization: Requires control over B, C, X, and Z axes.

- Dynamic Feed Control: The cutting tool must adapt its movement along the X-axis to accommodate the varying pitch curve radii.

- Force Characteristics: Cutting forces exhibit higher variability due to discontinuous cutting and differences in cutting conditions at various pitch curve points.

Equation for Basic Linkage Model

The hobbing movement can be modeled as:

where:

- : Rotation speed of the hob.

- : Radius at a specific pitch angle .

- : Constants based on gear and cutting conditions.

- : Feed velocity in the Z direction.

- : Helix angle of the gear.

2. Cutting Force Fluctuations

2.1. Nature of Fluctuations

During non-circular gear hobbing, cutting forces vary significantly due to:

- Changes in Cutting Depth: Variations in the pitch curve alter the contact area.

- Tool Engagement: Discontinuous cutting leads to periodic changes in force.

2.2. Mathematical Modeling

The cutting force is related to the undeformed chip area :

where is the specific cutting force. can be derived from the geometry of undeformed chips and cutting tool parameters.

3. Advanced Hobbing Models

3.1. Constant Arc Length Increment Model

To address force fluctuations, a constant arc length increment model has been proposed. This model ensures uniform cutting conditions by synchronizing the hob’s motion with the pitch curve, maintaining equal arc length increments per rotation.

Equation for Constant Arc Length

where is the polar angle.

4. Experimental Validation

4.1. Simulation of Cutting Forces

Using simulation software, cutting forces were analyzed for an elliptical gear with key parameters:

| Parameter | Value |

|---|---|

| Number of Teeth | 30 |

| Module (mm) | 4 |

| Helix Angle (°) | 15 |

| Eccentricity | 0.3 |

| Tool Diameter (mm) | 100 |

The results showed significant reductions in cutting force fluctuations with the constant arc length increment model.

4.2. Results and Observations

- Peak Forces: Reduced by 30%.

- Force Stability: Improved uniformity across the machining cycle.

5. Influence of Cutting Depth

Cutting depth directly influences cutting force variability. Experimental results show that a reduced cutting depth minimizes peak forces and ensures smoother machining.

Data Summary

| Cutting Depth | Max Force (N) | Force Variability (%) |

| Full Depth | 800 | 40 |

| Half Depth | 600 | 20 |

| Quarter Depth | 400 | 10 |

6. Conclusion

The study of gear hobbing in non-circular gears highlights the importance of advanced models and precise control to mitigate cutting force fluctuations. Techniques such as constant arc length increments and reduced cutting depths significantly improve machining stability and gear quality.