Introduction

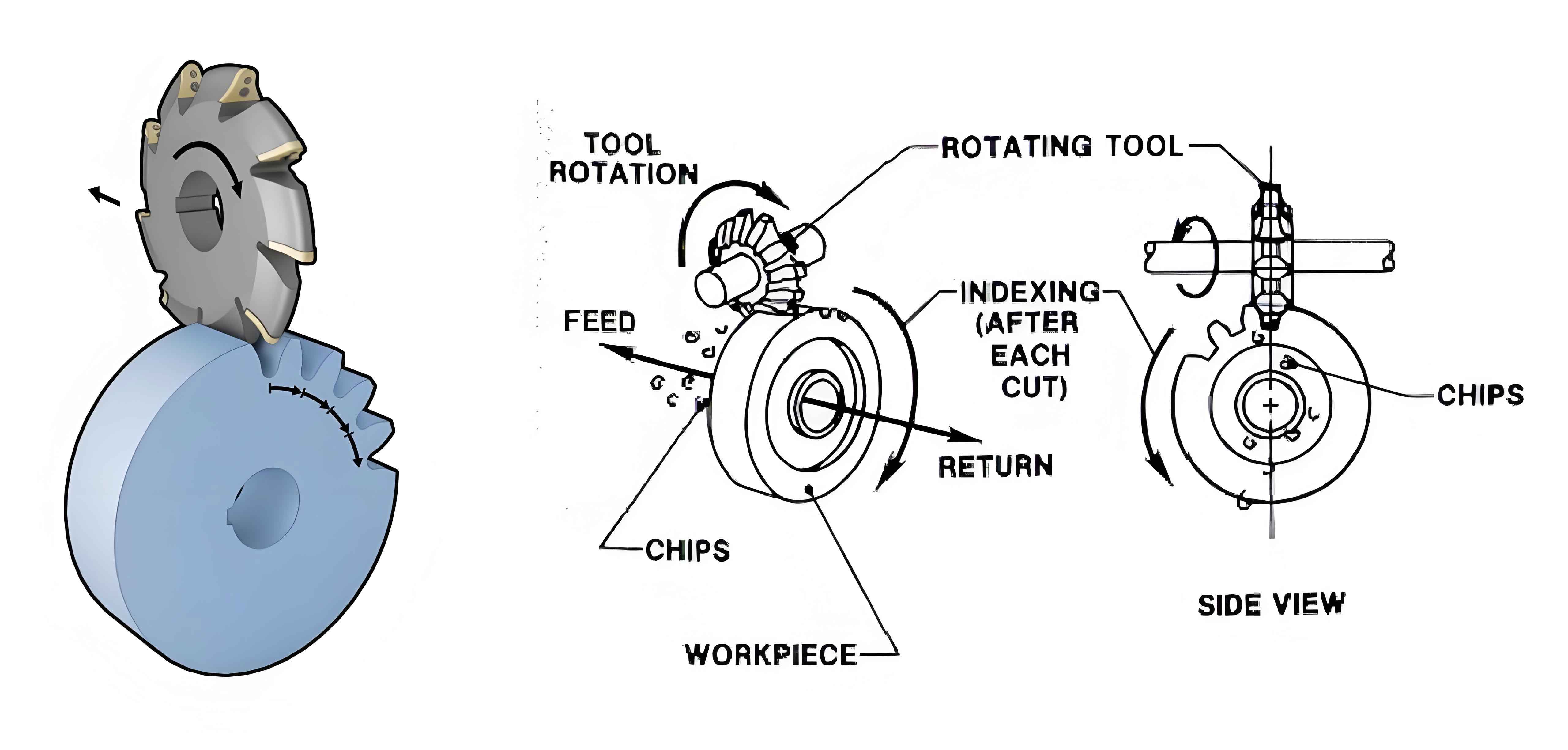

Spiral bevel gears are essential components in automotive and industrial applications, requiring high precision and dynamic stability during manufacturing. The performance of spiral bevel gear milling machines directly influences the quality, efficiency, and durability of the gears produced. Enhancing the dynamic characteristics of these machines is critical to achieving higher precision, reduced vibration, and extended service life.

This article explores the optimization of spiral bevel gear milling machines using dynamic testing, finite element methods (FEM), and sensitivity analysis. Key objectives include increasing the machine’s fundamental natural frequencies, reducing vibration amplitudes, and optimizing overall structural performance.

1. Dynamic Testing of Gear Milling Machines

1.1 Overview of Dynamic Testing

Dynamic testing involves analyzing the machine’s vibration behavior under operational conditions. A custom-developed signal acquisition and testing system measures the natural frequencies and vibration modes.

1.2 Testing Methodology

A hammer excitation method is used, with acceleration sensors capturing vibration signals. The acquired data helps identify the machine’s inherent dynamic characteristics.

| Modal Number | Frequency (Hz) | Mode Description |

|---|---|---|

| 1 | 28.921 | Tilting along the Y-axis |

| 2 | 65.334 | Torsional vibration around the Z-axis |

| 3 | 77.893 | Column rocking around the X-axis |

| 4 | 94.576 | Column rocking around the Y-axis |

| 5 | 147.964 | Bed vibration along the Z-axis |

| 6 | 158.367 | Column vibration along the Z-axis |

2. Finite Element Modeling and Analysis

2.1 Finite Element Method (FEM)

FEM divides the machine structure into finite elements, each governed by simplified equations. SolidWorks Simulation is employed to model and solve the structural dynamics.

2.2 Boundary Conditions

Boundary conditions are adjusted based on dynamic testing results to ensure simulation accuracy. A comparison between simulation and experimental results revealed a maximum relative error of 4.12%, validating the FEM model.

| Mode | Test Frequency (Hz) | FEM Frequency (Hz) | Error (%) |

| 1 | 28.921 | 27.322 | 4.12 |

| 2 | 65.334 | 62.379 | 4.52 |

| 3 | 77.893 | 79.559 | 2.14 |

3. Sensitivity Analysis

3.1 Sensitivity Overview

Sensitivity analysis evaluates how design variables affect the machine’s dynamic performance. Parameters like column height, base height, and transitional fillet radii are analyzed.

| Variable | Initial Value | Bending Sensitivity | Torsional Sensitivity |

| Column tilt angle (deg) | 162 | 65,230 | 34,251 |

| Transitional fillet radius (mm) | 200 | 55,240 | 28,650 |

| Column height (mm) | 3,000 | 58,770 | 39,248 |

| Base height (mm) | 1,000 | 17,589 | 12,360 |

4. Optimization Process

4.1 Optimization Goals

The optimization aims to:

- Increase natural frequencies above operational limits to avoid resonance.

- Minimize structural weight while maintaining stiffness.

4.2 Optimization Results

Using SolidWorks Simulation’s optimization tools, iterative calculations refined design parameters. Results include:

| Parameter | Initial Value | Optimized Value | Improvement |

| Column tilt angle (deg) | 162 | 154 | Increased stability |

| Fillet radius (mm) | 200 | 250 | Enhanced stiffness |

| Column height (mm) | 3,000 | 2,600 | Reduced weight |

| Base height (mm) | 1,000 | 800 | Improved dynamics |

5. Results and Discussion

5.1 Key Improvements

- Frequency Increase: The first natural frequency increased from 28.322 Hz to 41.572 Hz, a 46.8% improvement.

- Weight Reduction: Machine weight reduced by 2.1%, saving 454 kg of material.

- Vibration Reduction: Amplitudes decreased by 19.2% in Y-axis tilting and 21.7% in Z-axis torsion.

| Metric | Before Optimization | After Optimization | Change (%) |

| Y-axis tilting frequency (Hz) | 28.322 | 41.572 | +46.8 |

| Machine weight (kg) | 21,484 | 21,030 | -2.1 |

| Z-axis torsional vibration (mm) | 0.23 | 0.18 | -21.7 |

5.2 Extended Benefits

- Improved dynamic performance by 35%.

- Prolonged machine service life.

- Significant cost savings in material and operational efficiency.

Conclusion

Through dynamic testing, FEM analysis, and sensitivity optimization, this study enhanced the dynamic performance of spiral bevel gear milling machines. The methodology achieved significant frequency increases, weight reductions, and vibration minimizations, providing a robust framework for similar machine optimizations in the industry.