Abstract

In view of the complex structure, long transmission chain, poor precision, and low speed of traditional mechanical gear milling machines, which cannot meet the requirements of high-speed and high-precision gear processing, we designed the YKH200 CNC spiral bevel gear milling machine and the H218i CNC system. We analyzed the key component structures of the machine, conducted static and dynamic characteristic simulations and analyses of the CNC spiral bevel gear milling machine using the finite element method (FEM), and optimized the topological structure of the key part, the column. The results show that the static stiffness and the first two natural frequencies of the optimized column are improved compared to those before optimization. However, resonance may still occur under some high-speed cutting conditions. This paper provides a reference for improving the design to further enhance the stiffness of the entire machine and achieve gear machining at higher cutting speeds.

Keywords: spiral bevel gear; gear milling machine; finite element analysis; design; simulation analysis

1. Introduction

Many domestic universities have collaborated with enterprises to conduct research and develop products related to gear-cutting machines, achieving certain results in the key technology research and overall machine development of CNC spiral bevel gear milling machines. However, there is still a gap compared to advanced foreign gear-cutting machines, especially in spiral bevel gear processing technology and equipment. To address the aforementioned issues, this paper presents the design of the YKH200 CNC spiral bevel gear milling machine, conducts static and dynamic characteristic FEM simulations and analyses of the entire milling machine, and optimizes the topological structure of the key component, the column.

2. Overall Machine Design

2.1 Determination of the Design Scheme

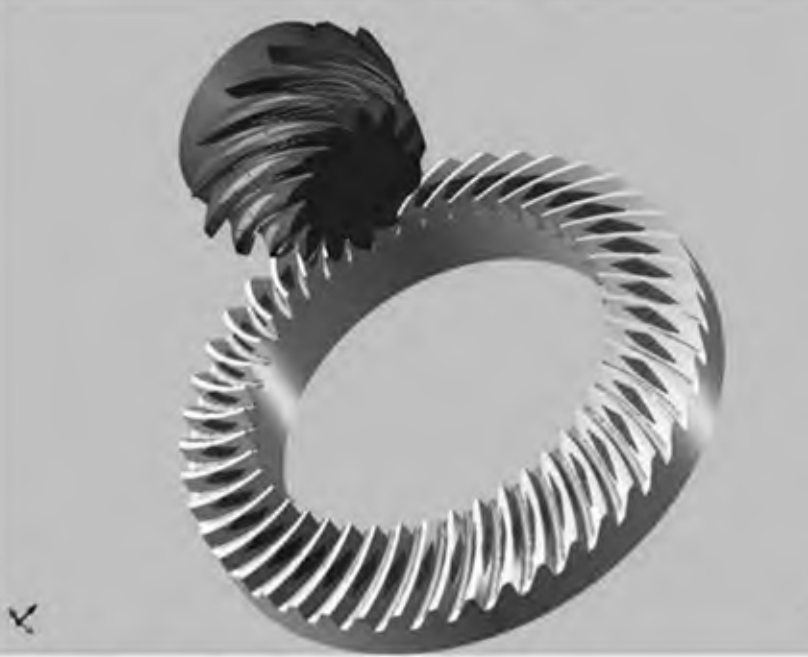

The YKH200 gear milling machine is a five-axis horizontal machine tool, mainly composed of a bed, saddle, toolbox, workpiece box, column, etc.. The entire machine is controlled using the Mailete H218i CNC system. The X, Y, and Z axes’ feed movements are realized by servo motors driving ball screw pairs, which drive the horizontal movement of the X-axis saddle, the horizontal movement of the column, and the vertical feed of the tool, respectively. The workpiece axis C and the tool axis B are directly driven by servo motors, which improves cutting efficiency, processing quality, and operational smoothness. The main technical parameters are shown in Table 1.

Table 1. Main Technical Parameters of the YKH200 CNC Spiral Bevel Gear Milling Machine

| Parameter Item | Value | Parameter Item | Value |

|---|---|---|---|

| Maximum Processing Diameter (mm) | 200 | Maximum Processing Modulus (mm) | 4 |

| Maximum Transmission Ratio | 10:1 | Maximum Full Tooth Depth (mm) | 8 |

| Workpiece Axis Taper Hole | Morse No. 5 | Tool Spindle Speed (r/min) | 100~350 |

| Machine Dimensions (L×W×H) (mm×mm×mm) | 2000×1500×2000 | Distance from Workpiece Axis End Face to Machine Center (mm) | 63 (when transmission ratio is 2:1), 200 (when transmission ratio is 10:1) |

| Maximum Tooth Surface Width (mm) | 30 | Processing Tooth Range (teeth) | 4~200 |

| Machine Mass (kg) | 3500 | Tool Disk Diameter | 2″~6″ |

| Drive Axis Torque (N·m) | X (Saddle): 11~160; Y (Vertical): 11~100; Z (Horizontal): 11~108; B (Tool Disk Axis): 3.7kW; C (Workpiece Axis): 16 | – | – |

2.2 Design of the Mechanical System

The design of the mechanical system includes the X-axis linear motion system, Y-axis linear feed motion system, Z-axis feed system, toolbox structure, and workpiece box structure. Detailed descriptions and diagrams of these components are provided, showcasing their configurations, bearings, drive mechanisms, and other critical features.

3. Static and Dynamic Characteristic Analysis of the Entire Machine

3.1 Simplification of the Model and Mesh Division

The model was simplified, and the mesh was divided for both static and dynamic analyses.

3.2 Static Analysis

The cutting force on the tool disk, F_C = 1050N, was decomposed into forces in various directions: F_Z = 945N, F_X = 630N, F_Y = 525N. The model was also subjected to self-weight loading. The static deformation cloud diagram showed that the maximum static deformation was 11.18 micrometers.

3.3 Modal Analysis of the Model’s Dynamic Performance

Modal analysis involves solving the equation |[K] – ω²[M]| = 0 to obtain the natural frequencies ω_i and corresponding mode shapes {φ_i} of the structure. The finite element simulation results and analysis of the machine’s modal analysis are presented, with a focus on avoiding or reducing vibrations during operation. The excitation frequency generated during high-speed cutting, such as when the tool disk has 16 teeth and rotates at a maximum speed of 800 r/min, is 213 Hz, which falls between the third and fourth natural frequencies of the entire machine, potentially causing resonance, leading to reduced workpiece surface accuracy and tool life.

4. Finite Element Analysis of the Column

4.1 Establishment of the Column Model

The column model was established for further analysis.

4.2 Static Analysis of the Column

Fixed constraints were applied to the two surfaces where the column contacts the sliders, and forces F_X = 2000N, F_Y = 12025N, F_Z = 1500N were applied to the two guide surfaces. The equivalent stress cloud diagram and total displacement cloud diagram were obtained. The maximum equivalent stress was 1.7963 MPa, occurring at the front end of the column base. The maximum displacement deformation at the top of the column was small, only 18.025 micrometers, indicating sufficient static stiffness of the column.

4.3 Modal Analysis of the Column

Constraints were applied to the contact surfaces between the column and the sliders, and the first six vibration modes were obtained. The first three vibration modes directly affect processing accuracy and cutting performance, while the last three have relatively minor impacts.

4.4 Optimization Design of the Column

The same constraints and loads as in the static analysis were applied to the column, with the volume set to be reduced by 45%. The topological optimization results indicated that the bottom plate of the column could be partially removed, and arc-shaped rib plates (20 mm thick) could be added at the corners of the lower plate to enhance stiffness. The secondary design structure of the column, with a mass of 441.44 kg. Modal analysis of the secondarily designed column structure is presented.

Table 6. First Two Natural Frequencies and Vibration Modes of the Optimized Column

| Order | Frequency (Hz) | Vibration Mode Description |

|---|---|---|

| 1 | 102.23 | Side plates and top plate of the column move left and right |

| 2 | 297.89 | Side plates and top plate of the column move forwards and backwards |

Table 7. Analysis Results Before and After Column Optimization

| Item | Maximum Deformation (mm) | Maximum Stress (MPa) | Mass (kg) | 1st Natural Frequency (Hz) | 2nd Natural Frequency (Hz) |

|---|---|---|---|---|---|

| Before Optimization | 0.018025 | 1.7963 | 476.32 | 100.25 | 297.16 |

| After Optimization | 0.017396 | 1.6738 | 441.44 | 102.23 | 297.89 |

| Comparison | -3.49% | -6.82% | -7.32% | +1.97% | +0.26% |

5. Conclusion

(1) The structural design of the YK200 CNC spiral bevel gear milling machine has been conducted, with a detailed analysis of the structures of the five major assemblies: the X/Y/Z/B/C five-axis feed system, the tool box, and the workpiece box.

(2) Finite element methods were employed to conduct static and dynamic characteristic simulation analyses of the CNC spiral bevel gear milling machine. The results indicate that the milling machine exhibits good stability when performing gear machining at conventional speeds.

(3) Structural optimization was carried out on the key large component, the column. Simulation results show that compared to the pre-optimization state, the optimized column exhibits improved static stiffness, first-order and second-order natural frequencies, with a 7.32% reduction in mass.

(4) Production and operational results demonstrate the stable performance of the milling machine.

(5) This paper provides a reference for improved design, further enhancing the overall stiffness of the machine, and enabling higher-speed gear machining on the machine tool.