1. Introduction

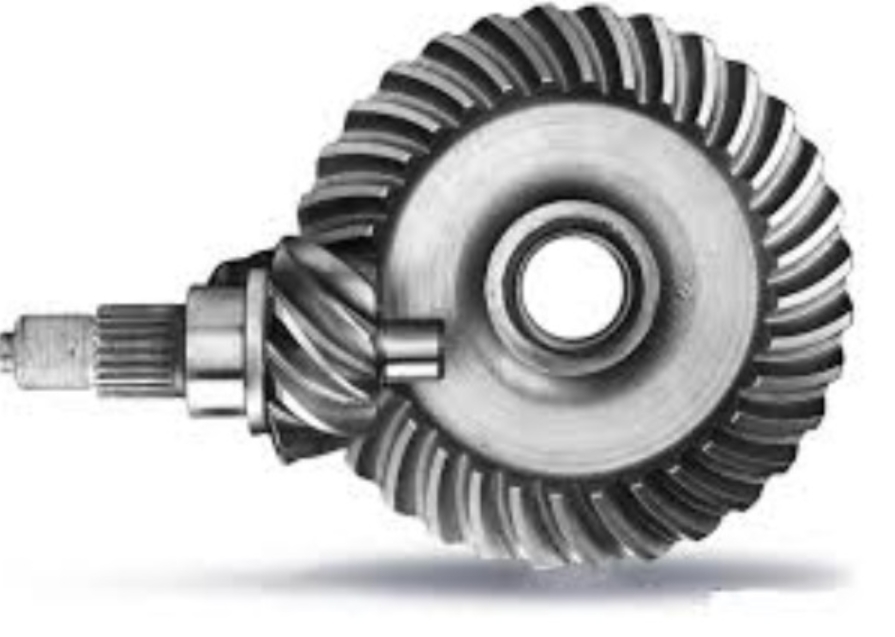

Modern mechanical systems demand increasingly higher power density, efficiency, and low-carbon performance. Among critical transmission components, hypoid gear stand out due to their compact design, high reduction ratios, and ability to handle intersecting axes with offset configurations. However, the complex topological surfaces of high-reduction hypoid (HRH) gears pose significant challenges in modeling, lubrication analysis, and efficiency optimization.

Recent studies have focused on tooth flank modifications to enhance meshing performance. For instance, Zhou et al. [1] explored the impact of different modification methods on gear dynamics, while Jiang et al. [2] optimized flank modifications to minimize wear. Despite these advancements, the coupling between geometric parameters and elastohydrodynamic lubrication (EHL) models remains a barrier, particularly for HRH gears with intricate spatial structures.

This study addresses these challenges by integrating dual equi-tangent conjugate modeling, loaded tooth contact analysis (LTCA), and mixed EHL friction models. A 3:60 HRH gear pair is analyzed to reveal the distribution of oil film thickness, friction coefficients, and power loss. Experimental validation further verifies the proposed methodology.

2. Geometric Modeling and Analysis of Hypoid Gear

2.1 Dual Equi-Tangent Conjugate Method

The geometric complexity of hypoid gear necessitates advanced modeling techniques. Using the dual equi-tangent conjugate principle, we constructed the tooth surface model and ease-off surfaces. Key coordinate systems and transformation matrices were defined to derive the conjugate pinion and gear surfaces.

The meshing equation for the pinion and generating gear is expressed as:Ucosϕg−Vsinϕg=WUcosϕg−Vsinϕg=W

where U,V,WU,V,W are simplified functions of geometric parameters (e.g., surface normals, tool positions). Solving this equation yields the conjugate pinion surface rc1(u2,θ2)rc1(u2,θ2).

2.2 Key Geometric Parameters

A 3:60 HRH gear pair with a 40 mm offset and 20 mm face width was modeled. Table 1 summarizes the cutting parameters used for gear fabrication.

Table 1: Cutting Parameters for HRH Gears

| Parameter | Pinion | Gear |

|---|---|---|

| Blade angle (°) | 10.9919 | 74.7639 |

| Radial setting (mm) | 51.9712 | 53.1513 |

| Cutter radius (mm) | 37.6 | 37.4 |

| Pressure angle (°) | 20.5 | 19.0 |

2.3 Ease-Off Surface Analysis

The ease-off surface, representing transmission error (TE), was derived using differential modifications. Figure 2 (simulated) shows a peak TE of 49.5 µm, ensuring controlled contact patterns and stress distribution.

3. Load Tooth Contact Analysis (LTCA)

3.1 Differential Element Method

LTCA was performed to resolve the coupling between geometric and mechanical parameters. The deformation-energy minimization principle governed the load distribution across contact lines. For each contact line ii, the deformation equation is:δi∑j=1mD(i,j)=F+∑j=1mD(i,j)zd(i,j)δij=1∑mD(i,j)=F+j=1∑mD(i,j)zd(i,j)

where D(i,j)D(i,j) is tooth stiffness, δiδi is deformation, and zd(i,j)zd(i,j) is the composite error.

Table 2: LTCA Results (T₂ = 200 N·m)

| Parameter | Value |

|---|---|

| Max contact stress | 1050 MPa |

| Load concentration | Central flank |

| Deformation range | 0.4–0.5 µm |

3.2 Contact Stress Distribution

Hertzian contact theory was adapted for finite elastic deformation. Subdividing the contact zone into cylindrical segments enabled stress calculation via:σh=182.38qjRjσh=182.38Rjqj

where qjqj is line load and RjRj is curvature radius.

4. Elastohydrodynamic Lubrication (EHL) Friction Power Loss

4.1 Oil Film Thickness Calculation

Using the Dawson-Hamrock formula, the minimum oil film thickness for each differential element was calculated:h0=3.06α0.56η00.69ve0.69Eq−0.03R0.41q−0.1h0=3.06α0.56η00.69ve0.69Eq−0.03R0.41q−0.1

where αα is the Barus viscosity-pressure coefficient.

Table 3: EHL Parameters

| Parameter | Value |

|---|---|

| Film thickness | 0.4–0.5 µm |

| Lubricant viscosity | 0.012 Pa·s |

| Pressure-viscosity | 15 GPa⁻¹ |

4.2 Friction Coefficient Models

Three lubrication regimes were considered:

- Boundary Lubrication (λ≤1λ≤1)μ=exp(a0+a1Sr+a2lnG)⋅Sca3μ=exp(a0+a1Sr+a2lnG)⋅Sca3

- Mixed EHL (1<λ≤31<λ≤3)μ=exp(b0+b1Sr)⋅Ub2Gb3μ=exp(b0+b1Sr)⋅Ub2Gb3

- Full-Film EHL (λ>3λ>3)μ=exp(c0+c1G)⋅Hc2μ=exp(c0+c1G)⋅Hc2

Table 4: Friction Coefficients Under Different Regimes

| Regime | Avg. μμ |

|---|---|

| Boundary | 0.12–0.15 |

| Mixed EHL | 0.08–0.10 |

| Full-Film EHL | 0.03–0.05 |

5. Efficiency Testing and Validation

5.1 Experimental Setup

A back-to-back test rig was used to measure transmission efficiency under varying speeds (1500–2400 rpm) and torques (50–250 N·m). Infrared thermography monitored temperature rise, while torque sensors recorded input/output power.

5.2 Results and Comparison

Table 5: Efficiency at 1800 rpm

| Torque (N·m) | Experimental (%) | Theoretical (%) | Error (%) |

|---|---|---|---|

| 100 | 82.1 | 83.5 | 1.4 |

| 150 | 79.45 | 80.7 | 1.25 |

| 200 | 75.0 | 77.2 | 2.2 |

The results validate the LTCA and EHL models, with discrepancies under 2.5%. Friction power loss peaks at 178.7 W under high torque (Figure 11).

6. Conclusion

This study presents a comprehensive framework for analyzing friction power loss and efficiency in hypoid gear. Key contributions include:

- A dual equi-tangent conjugate model for HRH gear geometry.

- A differential LTCA-EHL method for coupled parameter resolution.

- Experimental validation of meshing efficiency (75–84%).

Future work will focus on multi-objective optimization of hypoid gear for electric vehicle applications, integrating thermal and dynamic effects.