Abstract

The propose a systematic methodology to optimize the meshing efficiency of hypoid gear in drive axles using gear friction-loaded tooth contact analysis (FLTCA). By presetting peak-to-peak values of unloaded transmission errors and contact zone positions, we achieved tooth surface modification for both drive and coast sides of hypoid gear. An optimization model was established to maximize meshing efficiency under driving conditions while constraining loaded transmission errors, contact stress, and contact pattern distribution. To accelerate the optimization process, a Kriging surrogate model combined with a multi-island genetic algorithm (MIGA) was employed. Experimental validation on a commercial drive axle hypoid gear pair confirmed the effectiveness of the proposed method, demonstrating improved transmission efficiency and reduced power loss.

1. Introduction

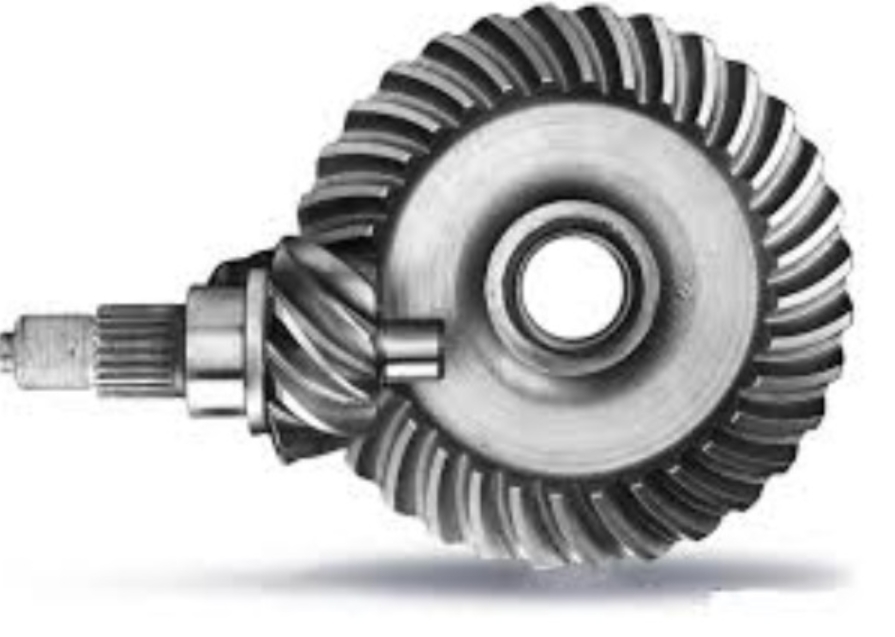

Hypoid gear is widely used in automotive drive axles due to their high load-carrying capacity and smooth operation. However, their complex geometry and sliding-dominated contact mechanics often lead to inefficiencies, noise, and wear. Enhancing meshing efficiency is critical for reducing energy consumption and meeting stringent emission standards. Traditional design methods for hypoid gear focus on geometric accuracy but neglect dynamic performance under loaded conditions. Our work addresses this gap by integrating tooth surface modification, FLTCA, and surrogate-based optimization to achieve a balance between efficiency, durability, and manufacturability.

2. Tooth Surface Modification Methodology

2.1 Preset Parameters for Unloaded Performance

Tooth surface modification begins with defining preset parameters for unloaded transmission error (UTE) and contact patterns. Key variables include:

- Contact line slope (kc,kvkc,kv)

- Contact ellipse semi-major axis (bc,bvbc,bv)

- Peak-to-peak UTE (PTEc,PTEvPTEc,PTEv)

These parameters ensure controlled contact distribution and minimize edge loading. Table 1 summarizes the design variables and their bounds.

Table 1: Design Variables and Constraints

| Variable | Symbol | Lower Bound | Upper Bound |

|---|---|---|---|

| Contact line slope | kk | 3 | 8 |

| Ellipse semi-axis | bb | 0.2 mm | 0.3 mm |

| Peak-to-peak UTE | PTEPTE | 0.00008 rad | 0.00012 rad |

2.2 Conjugate Tooth Surface Calculation

The modified tooth surfaces deviate from the conjugate profile to accommodate misalignments. Coordinate transformations account for axial (ΔP,ΔWΔP,ΔW), offset (ΔEΔE), and angular (ΔΣΔΣ) misalignments:M1=[100ΔP010ΔW001ΔE0001],M2=[cos(ΔΣ)sin(ΔΣ)00−sin(ΔΣ)cos(ΔΣ)0000100001]M1=100001000010ΔPΔWΔE1,M2=cos(ΔΣ)−sin(ΔΣ)00sin(ΔΣ)cos(ΔΣ)0000100001

The resulting tooth surface coordinates (r2mis,n2misr2mis,n2mis) ensure compatibility under misalignment.

3. Optimization Model for Meshing Efficiency

3.1 Objective and Constraints

The optimization aims to maximize meshing efficiency (ηη) while constraining:

- Loaded transmission error (PLTE≤50 μradPLTE≤50μrad)

- Contact stress (σp≤3300 MPaσp≤3300MPa)

- Edge contact area (ΔS≤1 mm2ΔS≤1mm2)

The mathematical formulation is:Find{kc,bc,PTEc,kv,bv,PTEv}MaximizeηSubject toPLTE≤PLTE0σp≤σp0ΔS≤ΔS0FindMaximizeSubject to{kc,bc,PTEc,kv,bv,PTEv}ηPLTE≤PLTE0σp≤σp0ΔS≤ΔS0

3.2 FLTCA Methodology

Friction-loaded tooth contact analysis (FLTCA) evaluates meshing performance under operational loads. Key equations include:

- Deformation compatibility:

∥δb+δs+δc−(Z−d0)∥2<ϵ1∥δb+δs+δc−(Z−d0)∥2<ϵ1

- Torque equilibrium:

∑i=1m∑j=1n(Ffij+FNij)rij⋅p−Tload<ϵ2i=1∑mj=1∑n(Ffij+FNij)rij⋅p−Tload<ϵ2

- Stress convergence:

Δσp=∥σp,k−σp,k−1∥2<ϵ3Δσp=∥σp,k−σp,k−1∥2<ϵ3

4. Surrogate-Based Optimization

4.1 Kriging Model and MIGA

To reduce computational cost, a Kriging surrogate model approximates the FLTCA responses. The model combines a global trend function and localized deviations:Y(X)=f(X)β+Z(X)Y(X)=f(X)β+Z(X)

where Z(X)Z(X) follows a Gaussian process with covariance:cov[Z(Xi),Z(Xj)]=σ2exp(−∑k=1tθk∣xk(i)−xk(j)∣2)cov[Z(Xi),Z(Xj)]=σ2exp(−k=1∑tθk∣xk(i)−xk(j)∣2)

Multi-island genetic algorithm (MIGA) efficiently explores the design space, balancing global and local search.

4.2 Optimization Workflow

- Sampling: Optimal Latin hypercube sampling (OLHS) generates initial training data.

- Surrogate training: Kriging models approximate ηη, PLTEPLTE, σpσp, and ΔSΔS.

- Iterative refinement: Expected improvement (EI) criteria add samples to improve accuracy.

- Convergence: MIGA identifies the optimal solution.

Table 2: Optimization Results

| Parameter | Initial Design | Optimized Design | Improvement |

|---|---|---|---|

| Meshing Efficiency | 92.1% | 94.5% | +2.4% |

| PLTEPLTE | 55 μradμrad | 43 μradμrad | -21.8% |

| Contact Stress | 3250 MPa | 3014 MPa | -7.3% |

5. Experimental Validation

5.1 Unloaded Contact Pattern Test

Figure 6 compares experimental and simulated contact patterns for drive and coast sides. The optimized hypoid gear shows centered contact zones without edge loading, validating the preset parameters.

5.2 Full-Axle Efficiency Test

Under a cruising load of 80 kW and 80 km/h, the optimized gear reduced power loss by 300 W (0.4% efficiency gain). Table 3 summarizes the results.

Table 3: Full-Axle Efficiency Comparison

| Load (kW) | Original Efficiency | Optimized Efficiency | Power Loss Reduction |

|---|---|---|---|

| 20 | 93.2% | 94.1% | 120 W |

| 40 | 92.8% | 93.9% | 210 W |

| 60 | 92.5% | 93.7% | 270 W |

| 80 | 92.0% | 93.6% | 300 W |

6. Conclusion

This study presents a comprehensive framework for optimizing hypoid gear meshing efficiency in drive axles. By integrating FLTCA, Kriging surrogates, and MIGA, we achieved a 2.4% efficiency improvement while ensuring durability and noise performance. Future work will extend this methodology to multi-objective optimization, considering thermal effects and lubrication dynamics.