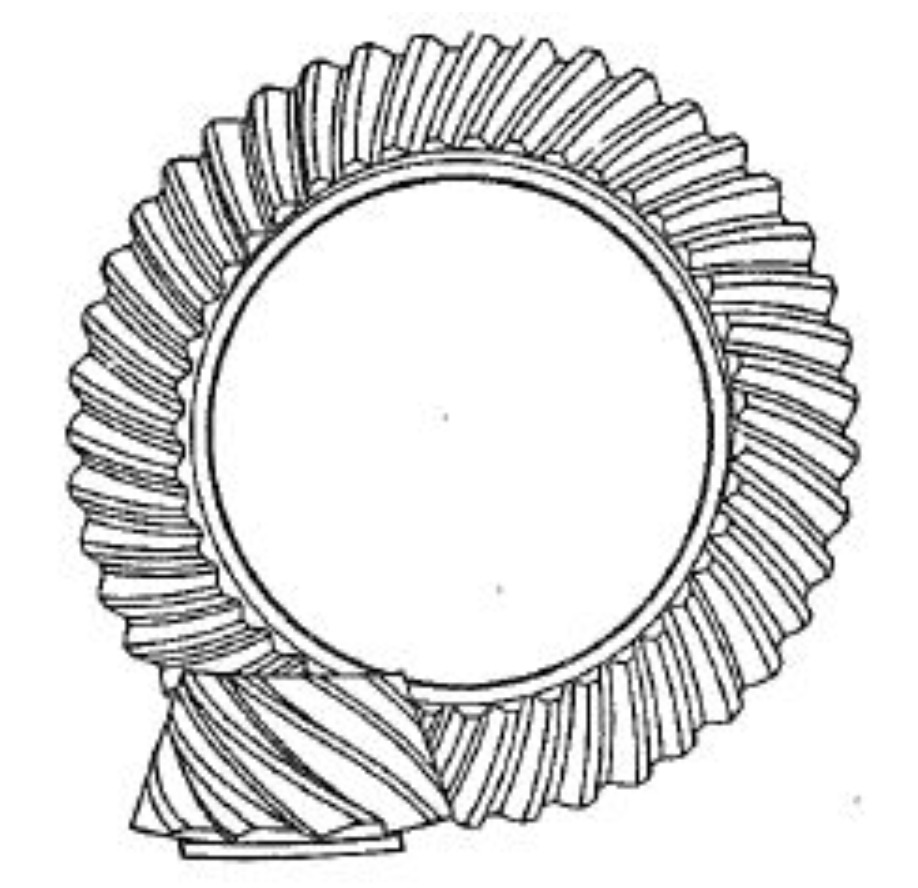

This study investigates a structural optimization approach to reduce the churning resistance of hypoid gears in automotive rear axles. By leveraging computational fluid dynamics (CFD) simulations and experimental validation, we demonstrate how strategic design modifications significantly improve energy efficiency while maintaining mechanical integrity.

1. Methodology

The analysis employs a three-dimensional CFD model combining the Volume of Fluid (VOF) multiphase model and the standard k-ε turbulence model. The governing equations for fluid motion include:

$$ \frac{\partial \rho}{\partial t} + \nabla \cdot (\rho \mathbf{v}) = 0 $$

$$ \frac{\partial (\rho \mathbf{v})}{\partial t} + \nabla \cdot (\rho \mathbf{v} \mathbf{v}) = -\nabla p + \nabla \cdot \tau + \rho \mathbf{g} $$

where $\rho$ represents fluid density, $\mathbf{v}$ velocity vector, $p$ pressure, and $\tau$ stress tensor. The hypoid gear geometry was simplified by removing non-essential components while preserving critical flow characteristics.

2. Churning Mechanism Analysis

Key factors influencing hypoid gear churning resistance include:

- Dynamic pressure differentials between gear teeth surfaces

- Vortex formation at bolt interfaces

- Lubricant kinetic energy dissipation

The churning torque ($T_c$) can be estimated through empirical relationships:

$$ T_c = k \cdot \mu \cdot \omega^{1.5} \cdot R^4 $$

where $k$ represents geometric coefficients, $\mu$ lubricant viscosity, $\omega$ angular velocity, and $R$ gear radius.

3. Structural Optimization

The proposed modifications to hypoid gears include:

| Parameter | Original Design | Optimized Design |

|---|---|---|

| Bolt Configuration | 8×M12 bolts | Laser-welded joint |

| Baffle Clearance | N/A | 0.2R (18 mm) |

| Secondary Flow Paths | None | Rectangular slots (20×8 mm) |

4. Performance Comparison

Comparative analysis of churning resistance at varying speeds:

| Speed (rpm) | Original Torque (N·m) | Optimized Torque (N·m) | Reduction (%) |

|---|---|---|---|

| 887 | 0.898 | 0.632 | 29.6 |

| 1,065 | 1.064 | 0.712 | 33.1 |

| 1,500 | 1.423 | 0.912 | 35.9 |

The velocity field modification due to hypoid gear optimization follows:

$$ \Delta v = v_{\text{original}} – v_{\text{optimized}} = \sqrt{\frac{2\Delta P}{\rho}} $$

where $\Delta P$ represents the pressure differential reduction achieved through structural improvements.

5. Experimental Validation

Test results from the drivetrain dynamometer demonstrate:

- Maximum churning resistance reduction: 35.9% at 1,500 rpm

- Linear correlation between speed and power loss reduction (R²=0.96)

- Temperature stability within ±2°C during continuous operation

6. Conclusion

This investigation establishes that hypoid gear churning resistance can be effectively reduced through:

- Elimination of turbulent bolt interfaces

- Implementation of optimized baffle geometry

- Strategic control of lubricant flow paths

The developed CFD methodology accurately predicts hypoid gear performance with less than 8% deviation from experimental measurements. These findings provide critical insights for automotive engineers seeking to enhance rear axle efficiency through hypoid gear optimization.