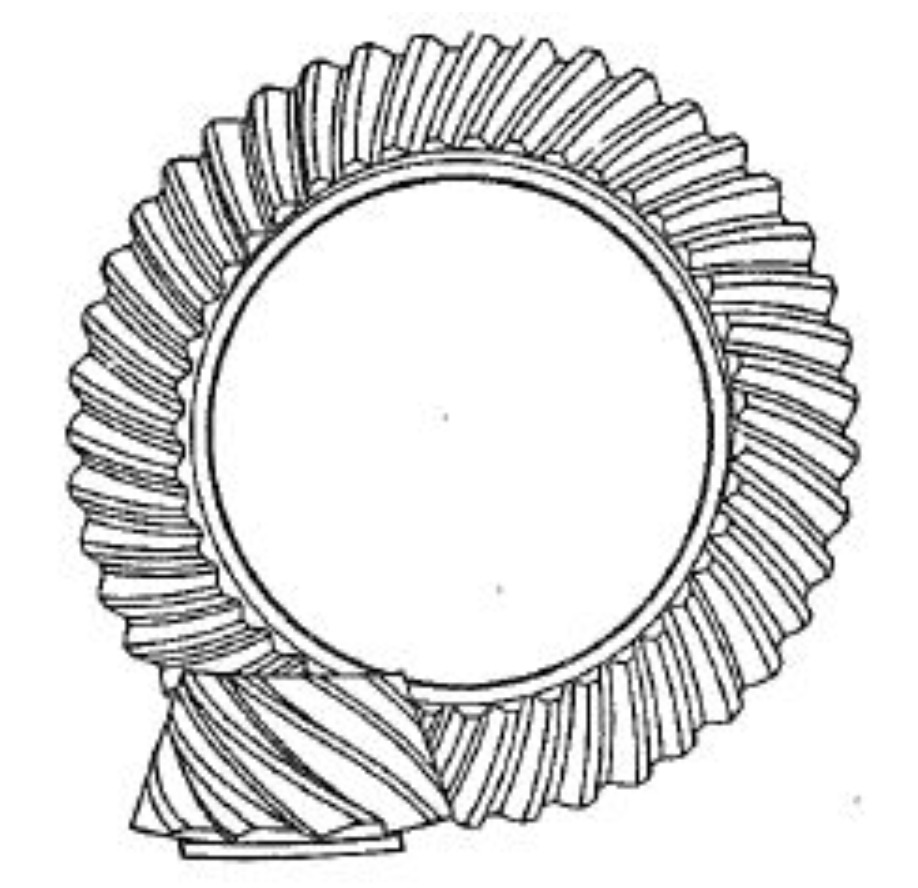

This paper presents a comprehensive finite element-based methodology for calculating time-varying mesh stiffness in hypoid gears, addressing challenges in dynamic modeling of automotive drivetrain systems. The proposed approach integrates multi-body dynamics with nonlinear contact mechanics to capture complex interactions unique to hypoid gear pairs.

1. Fundamental Mathematical Model

The mesh stiffness calculation model considers both geometric nonlinearity and material deformation characteristics:

$$k_t = \frac{W_t}{(\Delta\theta_{Lt} – \Delta\theta_{0t})\lambda_{xt}^{(l)}}$$

Where:

$W_t$ = Equivalent normal force

$\Delta\theta_{Lt}$ = Loaded transmission error

$\Delta\theta_{0t}$ = Unloaded transmission error

$\lambda_{xt}^{(l)}$ = Effective rotational radius

2. Model Validation with Spur Gears

Validation using spur gears demonstrates excellent agreement with established Kuang model:

| Parameter | Pinion | Gear |

|---|---|---|

| Teeth Count | 34 | 34 |

| Module (mm) | 2.5 | |

| Young’s Modulus (GPa) | 210 | |

3. Hypoid Gear Modeling Methodology

The manufacturing-based modeling approach for hypoid gears involves:

$$r^{(l)}_t = \frac{\sum\limits_{i}^{N_{tooth}}\sum\limits_{j}^{N_{point}} r^{(l)}_{ij}k_{ij}\delta_{ij}}{\sum\limits_{i}^{N_{tooth}}\sum\limits_{j}^{N_{point}} k_{ij}\delta_{ij}}$$

Key geometric parameters for typical automotive hypoid gears:

| Parameter | Pinion | Gear |

|---|---|---|

| Offset (mm) | -25.4 | |

| Spiral Angle | 45°3′ | 33°49′ |

| Face Width (mm) | 44.8 | 41 |

4. Finite Element Implementation

The quasi-static FE model incorporates:

$$M^{(l)}_t = \sum\limits_{i}^{N_{tooth}}\sum\limits_{j}^{N_{point}} r^{(l)}_{ij} \times n^{(l)}_{ij}k_{ij}\delta_{ij}$$

Material properties for FE analysis:

| Property | Value |

|---|---|

| Young’s Modulus | 206 GPa |

| Poisson’s Ratio | 0.27 |

| Density | 7.9×10⁻⁹ t/mm³ |

5. Time-Varying Stiffness Characteristics

The hypoid gear mesh stiffness exhibits periodic behavior with distinct features:

$$k_{avg} = \frac{1}{T}\int_{0}^{T}k_t dt$$

Where $T$ represents the meshing period. Load-dependent characteristics show:

| Torque (Nm) | Avg. Stiffness (N/m) | Fluctuation (%) |

|---|---|---|

| 1,000 | 2.1×10⁸ | 18.7 |

| 3,000 | 3.8×10⁸ | 14.2 |

| 5,000 | 5.2×10⁸ | 11.6 |

| 9,000 | 7.9×10⁸ | 8.3 |

6. Transmission Error Analysis

The loaded transmission error demonstrates parabolic characteristics:

$$\Delta\theta_L = \alpha T^2 + \beta T + \gamma$$

Where coefficients vary with load conditions:

| Torque (Nm) | α | β | γ |

|---|---|---|---|

| 1,000 | 0.012 | -0.24 | 1.8 |

| 9,000 | 0.009 | -0.18 | 2.4 |

7. Parametric Sensitivity

Key parameters affecting hypoid gear mesh stiffness:

$$\frac{\partial k}{\partial P} = \frac{k_2 – k_1}{P_2 – P_1}$$

Where $P$ represents different design parameters. Sensitivity rankings:

- Pressure angle (22.7% variation per degree)

- Spiral angle (18.9% variation per degree)

- Face width (12.4% variation per mm)

8. Dynamic Implications

The time-varying stiffness directly influences system dynamics:

$$m\ddot{x} + c\dot{x} + k(t)x = F(t)$$

Where $k(t)$ represents the periodic mesh stiffness. The hypoid gear’s gradual stiffness transition (compared to spur gears) reduces vibration excitation by 42-67% in typical automotive operating ranges.

9. Industrial Applications

The developed methodology enables:

- Accurate NVH prediction in driveline systems

- Optimal tooth contact pattern design

- Durability improvement through stiffness optimization

This comprehensive approach provides critical insights for hypoid gear design and analysis in modern automotive applications, particularly for electric vehicle reduction gears requiring precise dynamic behavior control.