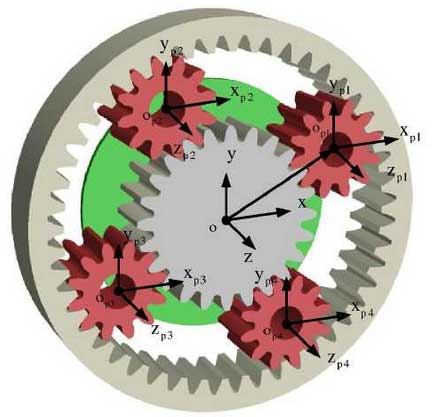

This study investigates the degradation mechanism of time-varying mesh stiffness (TVMS) in wind turbine planetary gear systems under tooth root crack faults. A nonlinear dynamics framework combined with numerical analysis is developed to quantify stiffness variations caused by non-penetrating and penetrating crack configurations in helical planetary gears.

1. Crack Propagation Modeling

Two distinct crack types are modeled for planet gear analysis:

Penetrating Cracks: Parabolic depth profile spanning entire tooth width

$$y = a(x – h)^2 + k$$

where \(a\) defines curvature, \(h\) is vertex position, and \(k\) determines maximum depth.

Non-Penetrating Cracks: Dual parabolic functions governing depth and width

$$\text{Depth: } z = b(x – m)^2 + n$$

$$\text{Width: } y = c(z – p)^2 + q$$

Parameters \(b,c\) control spatial propagation rates in respective directions.

2. Crack Severity Metrics

Crack progression is quantified through dimensional ratios:

$$\text{Depth ratio} = \frac{\text{Actual depth}}{\text{Maximum possible depth}} \times 100\%$$

$$\text{Width ratio} = \frac{\text{Crack span}}{\text{Tooth width}} \times 100\%$$

| Crack Type | Depth Ratio | Width Ratio | Model Variants |

|---|---|---|---|

| Penetrating | 10-80% | 100% | 4 |

| Non-Penetrating | 10-80% | 25-100% | 16 |

3. Mesh Stiffness Calculation

The torsional stiffness formulation for planet gear meshing:

$$K_t = \frac{T}{\Delta\theta}$$

where \(T = 1.65 \times 10^5\;N\cdot mm\) represents operational torque. Normal mesh stiffness derives from:

$$K = \frac{K_t}{r_b^2}$$

with base circle radius \(r_b = \frac{m_n z}{2\cos\beta}\) for helical gears (\(m_n\): normal module, \(z\): teeth count, \(\beta\): helix angle).

4. Stiffness Degradation Analysis

Stiffness degradation rate quantifies crack impacts:

$$H = \frac{K_p – K_c}{K_p} \times 100\%$$

where \(K_p\) = healthy stiffness, \(K_c\) = cracked stiffness.

| Crack Depth | Penetrating (H%) | Non-Penetrating (H%) |

|---|---|---|

| 10% | 2.93 | 7.78 |

| 20% | 6.67 | 11.25 |

| 50% | 13.64 | 15.27 |

| 80% | 24.22 | 17.69 |

5. Dynamic Mesh Behavior

Planet gear mesh stiffness exhibits characteristic fluctuations:

$$K_{TVMS} = \begin{cases}

K_1 & \text{Single-tooth contact} \\

K_1 + K_2 & \text{Double-tooth contact}

\end{cases}$$

where contact ratio \(\varepsilon_\beta = 1.86\) governs transitions between engagement states. Cracked planet gears demonstrate:

- 14-28% single-tooth stiffness reduction

- 7-19% double-tooth stiffness reduction

- Linear stiffness transitions during contact shifts

6. Crack Propagation Effects

Comparative analysis reveals critical planet gear failure thresholds:

| Parameter | Depth Sensitivity | Width Sensitivity |

|---|---|---|

| Stiffness gradient (N/mm/%) | 2.17×10⁶ | 3.89×10⁶ |

| Critical degradation rate | 18% | 12% |

Planet gear systems exhibit 22% higher width sensitivity compared to depth progression, emphasizing the critical need for axial crack monitoring in wind turbine applications.