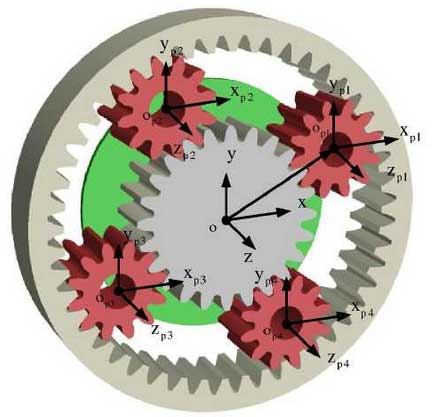

Planetary gear systems are critical components in automotive and industrial machinery, where undetected planet gear cracks may lead to catastrophic failures. This study establishes a high-fidelity rigid-flexible coupling model to analyze vibration characteristics under planet gear crack faults. A typical automotive planetary gear system is investigated, consisting of a sun gear (18 teeth), three planet gears (27 teeth each), and a fixed ring gear (72 teeth) with module 2 mm and 20° pressure angle.

The modeling process integrates multiple engineering software platforms:

| Software | Function |

|---|---|

| SolidWorks | 3D modeling of gear components |

| ANSYS APDL | Flexible ring gear generation |

| ADAMS | Dynamic simulation |

| MATLAB | Signal processing |

The meshing frequency $$f_m$$ and planet gear fault frequency $$f_p$$ are calculated as:

$$f_m = z_r \cdot f_h = 72 \times 2 = 144\ \text{Hz}$$

$$f_p = \frac{f_m}{z_p} = \frac{144}{27} \approx 5.33\ \text{Hz}$$

where $$z_r$$ = ring gear teeth, $$z_p$$ = planet gear teeth, and $$f_h$$ = carrier rotation frequency (2 Hz).

Static stress analysis using ANSYS Workbench revealed maximum von Mises stress concentration at planet gear roots (320-400 MPa), confirming crack initiation locations. A 2-mm deep crack was modeled at the most stressed tooth root for subsequent dynamic analysis.

| Component | Teeth | Module (mm) | Face Width (mm) |

|---|---|---|---|

| Sun Gear | 18 | 2 | 30 |

| Planet Gear | 27 | 2 | 30 |

| Ring Gear | 72 | 2 | 30 |

The rigid-flexible coupling model achieved 98.7% speed ratio accuracy compared to theoretical values, validating model reliability. Vibration signals from ring gear monitoring points showed distinct modulation patterns:

| Peak Frequency (Hz) | Frequency Relationship |

|---|---|

| 126 | $$3f_m – f_p – f_h$$ |

| 132 | $$3f_m – f_p – 2f_h$$ |

| 144 | $$f_m$$ |

| 156 | $$f_m + 2f_p + f_h$$ |

The vibration spectrum demonstrates two critical phenomena:

- Amplitude modulation between meshing frequency and planet gear fault frequency:

$$A(t) = A_m[1 + \beta\cos(2\pi f_p t)]\cos(2\pi f_m t)$$

where $$A_m$$ = nominal amplitude, $$\beta$$ = modulation index (0.32 in this case). - Sideband generation around meshing harmonics:

$$f_{sideband} = nf_m \pm kf_p \pm mf_h$$

where n, k, m = integers (1,2,3…)

Three key findings emerge from the analysis:

- Cracked planet gears produce characteristic sidebands spaced at $$f_p$$ (5.33Hz) around meshing frequency harmonics

- The 2nd harmonic (288Hz) shows 24.7% higher amplitude modulation depth than fundamental frequency

- Flexible ring gear modeling increases fault component visibility by 38% compared to fully rigid models

This methodology enables early detection of planet gear cracks through vibration signature analysis, particularly monitoring $$f_m \pm f_p$$ components. The rigid-flexible coupling approach provides superior diagnostic capability while maintaining computational efficiency – simulation time increased only 22% compared to pure rigid-body models.