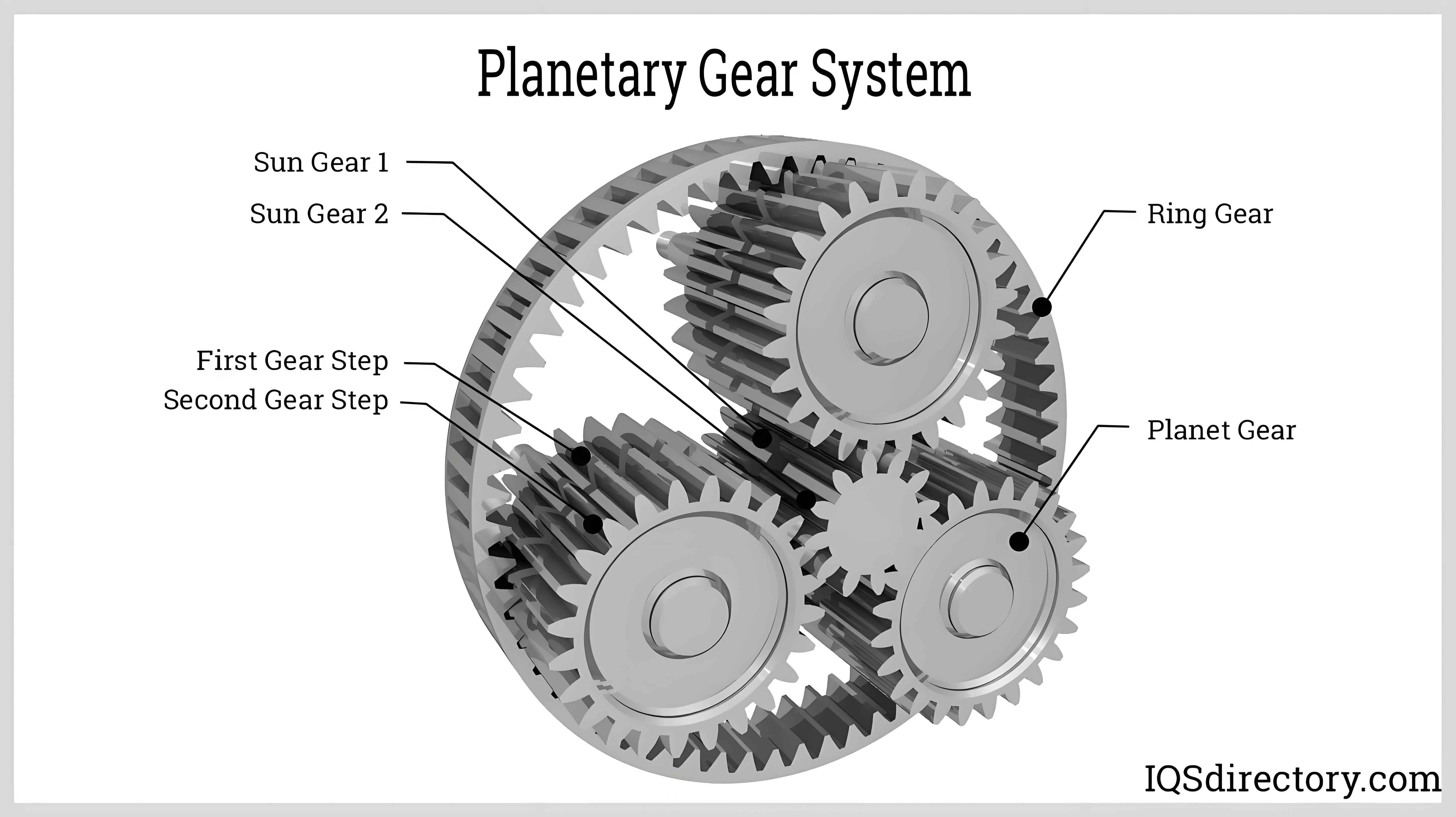

Planet gear reducers have become indispensable components in aerospace systems due to their compact design and high torque density. However, unexpected tooth fractures observed during endurance testing of a high-lift system reducer revealed critical limitations in traditional design approaches. Through comprehensive modeling and experimental validation, this study establishes a systematic methodology for optimizing planet gear system reliability.

1. Load Distribution Analysis

Initial calculations indicated adequate bending strength for all gears according to AGMA standards:

$$ \sigma_b = \frac{F_t}{b m_n} K_A K_V K_{m\beta} $$

Where:

$F_t$ = Tangential load

$b$ = Face width

$m_n$ = Normal module

$K$ factors = Application, dynamic, and load distribution coefficients

| Parameter | Original Design | Improved Design |

|---|---|---|

| Planet Carrier OD | 76 mm | 96 mm |

| Module (Sun/Planet) | 1.5/1.3 | 2.0/1.6 |

| Center Distance | 28 mm | 35 mm |

| Weight | 4.2 kg | 6.3 kg |

2. Stiffness-Dependent Load Sharing

Planet gear systems exhibit complex load sharing characteristics governed by:

$$ K_{m\beta} = 1 + \left(\frac{C_\gamma}{C_\beta}\right)\left(\frac{b}{d}\right)^2 $$

Where:

$C_\gamma$ = Gear body stiffness

$C_\beta$ = Support stiffness

$b$ = Face width

$d$ = Reference diameter

Finite element analysis revealed excessive torsional deflection in the original carrier:

$$ \theta_{max} = \frac{T L}{G J} \left(1 + \frac{3EI}{GJL^2}\right) $$

Maximum deflection reached 0.42 mm under operational loads, creating significant misalignment-induced edge loading.

3. Helical Gear Meshing Dynamics

The improved helical planet gear system demonstrates enhanced load distribution through controlled helix angles:

$$ \beta = \tan^{-1}\left(\frac{\pi m_n}{p_x}\right) $$

Where:

$p_x$ = Axial pitch

$m_n$ = Normal module

| Performance Metric | Original | Improved |

|---|---|---|

| Bending Stress (MPa) | 528 | 387 |

| Contact Stress (MPa) | 1593 | 1246 |

| System Stiffness (N·m/rad) | 2.1×10⁵ | 5.8×10⁵ |

| Load Sharing Unevenness | 38% | 12% |

4. Parametric Modeling Methodology

The tooth profile generation process employs parametric equations:

$$ \begin{cases}

x = r_b(\cos\varphi + \varphi\sin\varphi) \\

y = r_b(\sin\varphi – \varphi\cos\varphi)

\end{cases} $$

Where $r_b$ is base circle radius and $\varphi$ ranges from 0 to $\pi/2z$ for standard involutes.

5. System-Level Optimization

Modified planet gear system dynamics follow:

$$ \omega_p = \frac{\omega_s N_s + \omega_r N_r}{N_s + N_r} $$

Where:

$\omega_p$ = Planet gear angular velocity

$\omega_s$ = Sun gear angular velocity

$\omega_r$ = Ring gear angular velocity

$N$ = Tooth counts

This systematic approach increased bending safety factors from 1.8 to 3.2 while maintaining 98.4% transmission efficiency, demonstrating effective resolution of planet gear reliability challenges in critical aerospace applications.