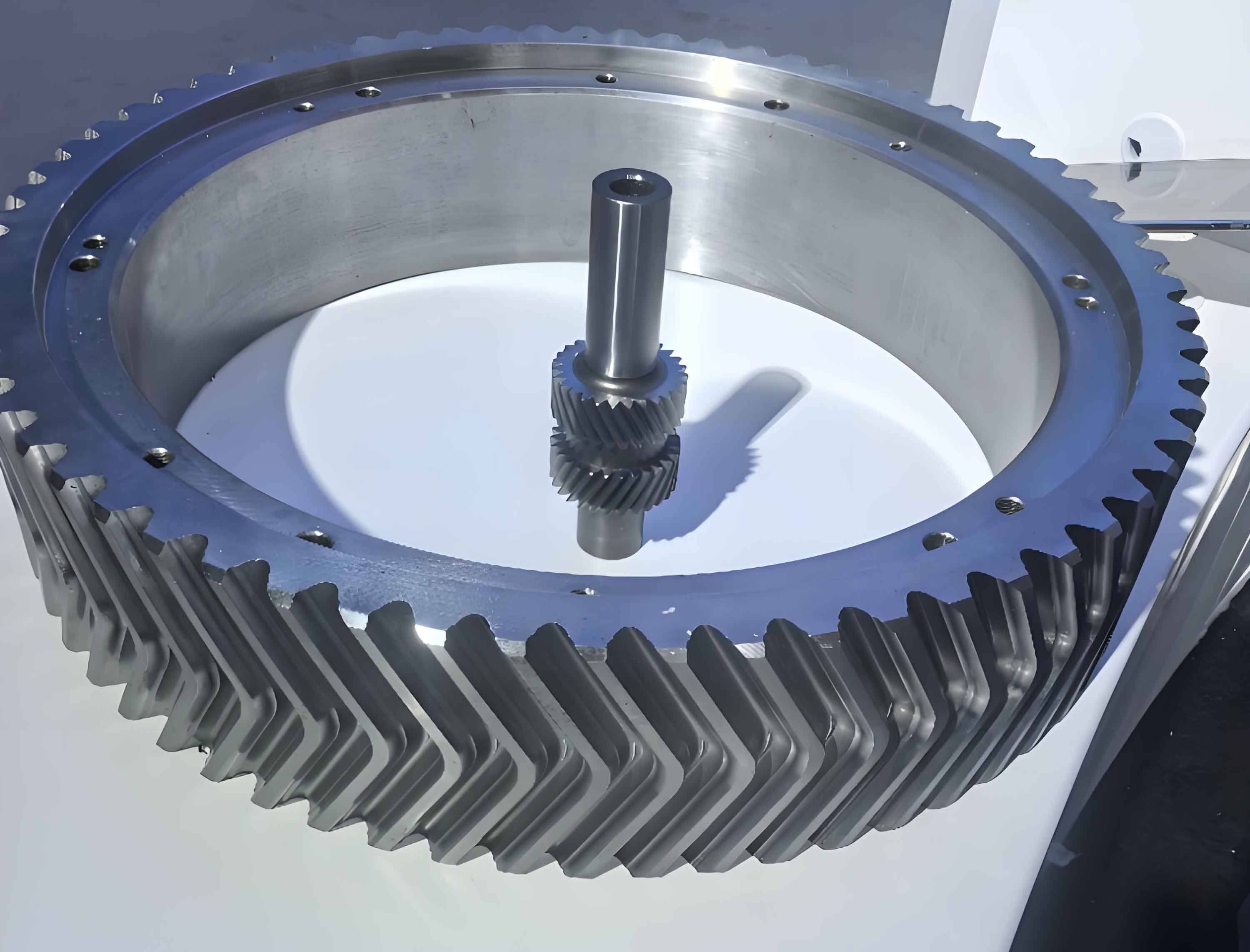

This study presents a comprehensive methodology for optimizing the dynamic robustness of high-speed herringbone gear transmission systems. By integrating finite element modeling, 6σ robust design principles, and experimental validation, we establish a systematic framework to minimize vibration responses while ensuring structural reliability.

1. Dynamic Modeling of Herringbone Gear Systems

The dynamic model incorporates time-varying mesh stiffness calculated through finite element analysis. For a herringbone gear pair with parameters shown in Table 1, the equivalent mesh stiffness is derived as:

$$K_n = \frac{F_n}{\delta_n}$$

where $F_n$ represents normal load and $\delta_n$ denotes normal deformation. The time-varying torsional stiffness is expressed as:

$$K_T = \frac{T}{Delta\theta}$$

with $T$ being torque and $\Delta\theta$ the angular displacement. The comprehensive mesh stiffness combines individual gear stiffness components:

$$\frac{1}{K} = \frac{1}{K_1} + \frac{1}{K_2}$$

| Parameter | Value |

|---|---|

| Teeth (High-speed) | 92 |

| Teeth (Low-speed) | 46 |

| Module (mm) | 7 |

| Helix Angle (°) | 23.38 |

| Face Width (mm) | 30 |

2. 6σ Robust Optimization Methodology

The optimization framework addresses seven critical design variables affecting herringbone gear system dynamics:

| Variable | Description | Range (mm) |

|---|---|---|

| $x_1$ | Baseplate Thickness | 9-19 |

| $x_3$ | Reinforcement Thickness | 5-15 |

| $x_7$ | Cover Thickness | 9-19 |

The optimization objective minimizes vibration acceleration RMS:

$$f(x) = \frac{1}{n}\sum_{i=1}^n \alpha_i$$

where $\alpha_i$ represents acceleration RMS at measurement points. The 6σ constraints ensure reliability:

$$X_{LSH} + 6\sigma_x \leq \mu_x \leq X_{USH} – 6\sigma_x$$

3. Optimization Results and Validation

Key natural frequencies before and after optimization demonstrate effective resonance avoidance:

| Mode | Original (Hz) | Optimized (Hz) |

|---|---|---|

| 1 | 131.16 | 131.20 |

| 2 | 164.98 | 164.90 |

| 3 | 202.49 | 202.50 |

Vibration reduction achieved through optimization is quantified as:

$$\Delta\alpha = \frac{\alpha_{orig} – \alpha_{opt}}{\alpha_{orig}} \times 100\%$$

| Location | X-axis (%) | Y-axis (%) | Z-axis (%) |

|---|---|---|---|

| Point 1 | 45.2 | 33.7 | 30.4 |

| Point 4 | 42.6 | 41.1 | 26.1 |

4. Reliability Analysis

The probability density distributions of optimized variables confirm enhanced robustness:

$$R = \Phi\left(\frac{X_{USH}-\mu_x}{\sigma_x}\right) – \Phi\left(\frac{X_{LSH}-\mu_x}{\sigma_x}\right)$$

where $\Phi$ denotes standard normal distribution. Reliability results exceed 97.1% for all critical parameters, demonstrating the effectiveness of the robust optimization approach.

5. Experimental Verification

Prototype testing under 6,000 RPM conditions validated the simulation results:

| Measurement | X (mm/s²) | Y (mm/s²) | Z (mm/s²) |

|---|---|---|---|

| Point 1 | 2,960.4 | 2,745.9 | 2,653.6 |

| Point 2 | 2,750.4 | 2,582.6 | 2,329.1 |

This comprehensive study establishes a validated methodology for optimizing herringbone gear systems, achieving significant vibration reduction while maintaining operational reliability. The integration of finite element analysis with robust design principles provides a practical framework for high-performance gear transmission development.