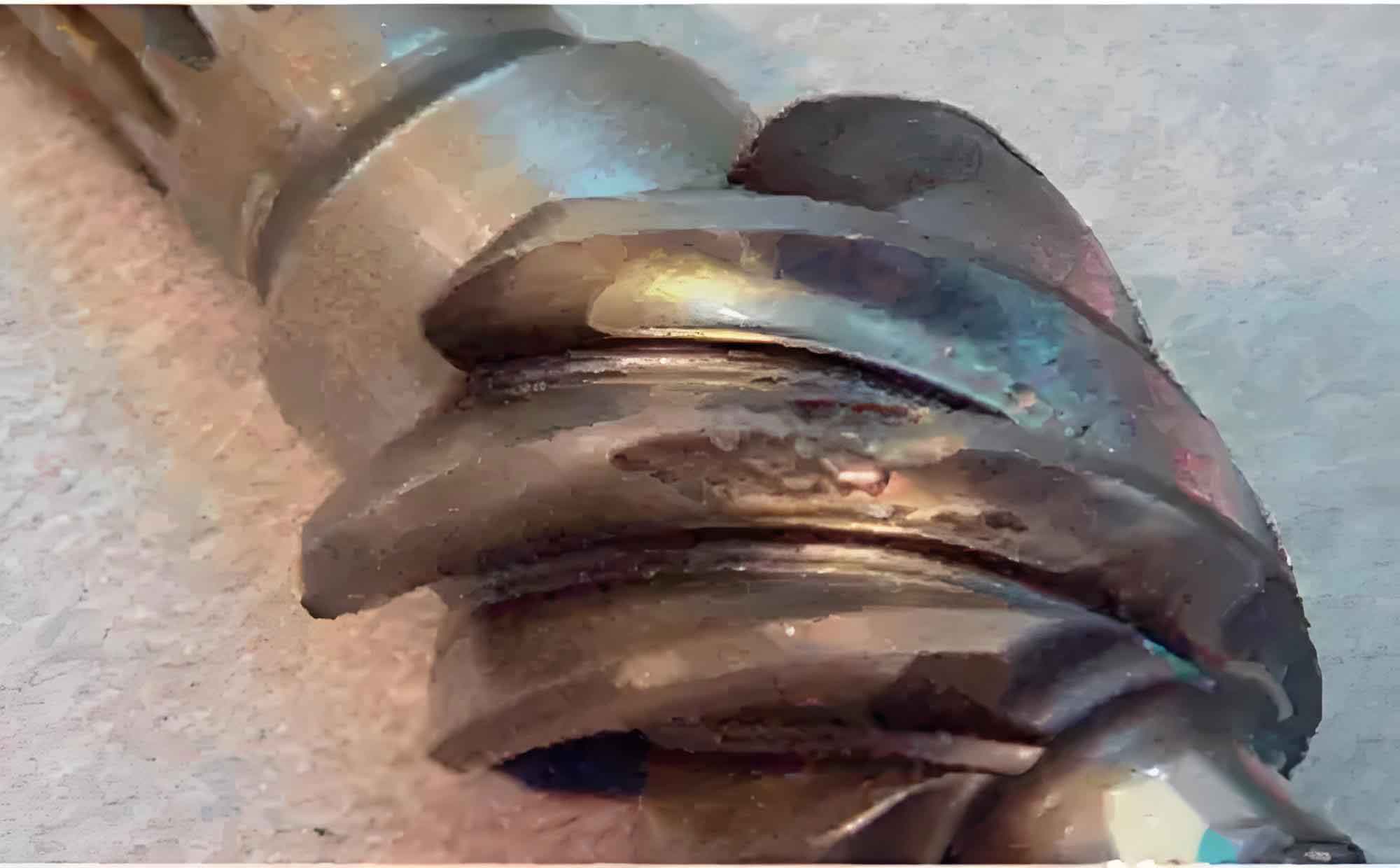

Gear transmission systems serve as critical components in locomotives, transferring traction motor power to wheelsets. Increasing operational speeds and loads intensify dynamic wheel-rail interactions, accelerating gear failure through crack initiation and propagation under complex excitations. This research comprehensively investigates how wheel polygonization and rail corrugation affect cracked gear dynamics through numerical simulations and finite element analysis.

1. Time-Varying Mesh Stiffness Calculation

Energy methods model gear teeth as variable-section cantilevers where total deformation combines Hertzian contact, bending, shear, and axial compression effects. The composite mesh stiffness $p_t$ is calculated as:

$$ p_t = \frac{1}{\frac{1}{p_h} + \sum_{i=1}^{2} \left( \frac{1}{p_{b_i}} + \frac{1}{p_{s_i}} + \frac{1}{p_{a_i}} + \frac{1}{p_{f_i}} \right)} $$

where subscripts denote Hertzian ($h$), bending ($b$), shear ($s$), axial ($a$), and foundation ($f$) stiffness components for driving (1) and driven (2) gears. Crack propagation significantly degrades stiffness:

| Crack Depth (mm) | Stiffness Reduction (%) | Crack Angle (°) | Stiffness Reduction (%) |

|---|---|---|---|

| 0 (Healthy) | 0 | 0 | 0 |

| 1.0 | 12.4 | 15 | 6.8 |

| 2.0 | 27.6 | 30 | 15.2 |

| 3.0 | 48.3 | 45 | 31.7 |

2. Dynamic Response Analysis

A 6-DOF lumped parameter model captures gear dynamics:

$$ \begin{cases}

m_1 \ddot{j}_1 + c_{j1} \dot{j}_1 + p_{j1} j_1 – F_f = 0 \\

m_2 \ddot{j}_2 + c_{j2} \dot{j}_2 + p_{j2} j_2 – F_f = 0 \\

m_1 \ddot{z}_1 + c_{z1} \dot{z}_1 + p_{z1} z_1 + (p_t z + c_t \dot{z}) = 0 \\

m_2 \ddot{z}_2 + c_{z2} \dot{z}_2 + p_{z2} z_2 – (p_t z + c_t \dot{z}) = 0 \\

I_1 \ddot{\theta}_1 – R_{b1} (p_t z + c_t \dot{z}) – M_1 = T_1 \\

I_2 \ddot{\theta}_2 + R_{b2} (p_t z + c_t \dot{z}) – M_2 = -T_2

\end{cases} $$

where $m_i$, $I_i$, $c_i$, $p_i$ denote mass, inertia, damping, and stiffness; $j_i$, $z_i$, $\theta_i$ represent translational and rotational displacements; $F_f$ is sliding friction; $T_i$ are torques. Newmark-$\beta$ integration reveals vibration amplification during gear failure progression:

| Statistical Indicator | Sensitivity to Crack Depth (Slope) | Fault Detection Effectiveness |

|---|---|---|

| Peak Value | 0.38 | Medium |

| RMS | 0.29 | Low |

| Kurtosis | 0.67 | High |

| Pulse Factor | 0.82 | Excellent |

| Crest Factor | 0.51 | Medium |

3. Wheel-Rail Excitation Effects

Locomotive-track coupled dynamics simulate excitation transfer to gears. Wheel polygonization (18th-24th order) and rail corrugation (0.5-1.5mm depth) significantly degrade gear contact characteristics:

$$ L = \frac{m W r_1}{n r_2}, \quad W = 0.84 + 0.012v + 0.000313v^2 $$

where $L$ is driven gear torque, $m$ is vehicle mass, $W$ is motion resistance, $v$ is velocity (km/h), $r_1$, $r_2$ are wheel and gear radii. Contact forces escalate under excitation:

Wheel Polygonization (24th order):

– Maximum contact force: 1178 N (3.0× healthy condition)

– Crack tip stress: 487 MPa (2.8× baseline)

Rail Corrugation (1.5mm depth):

– Maximum contact force: 2482 N (6.4× healthy condition)

– Crack tip stress: 512 MPa (3.0× baseline)

4. Stress Intensity Factors

XFEM analyzes crack propagation using J-integral contours. Mode I dominates gear failure:

$$ K_I = V \sigma \sqrt{\pi \epsilon}, \quad K_I > K_{II} \quad (5:1 \text{ magnitude ratio}) $$

Stress intensity factors evolve with crack length $\epsilon$ and load $F$:

$$ \begin{cases}

K_I = 2.18\epsilon^{0.67} F^{0.83} \\

K_{II} = 0.42\epsilon^{0.31} F^{0.76} \quad (\text{Peaks at } \epsilon \approx 1.8\text{mm}) \\

J = 1.87\epsilon^{1.02} F^{1.24}

\end{cases} $$

Wheel-rail excitations increase stress intensity factors by 35-80%, accelerating crack growth rates and reducing gear life by 40-65%.

5. Conclusion

This investigation demonstrates that wheel polygonization and rail corrugation significantly exacerbate gear failure dynamics. Key findings include:

- Time-varying mesh stiffness decreases by 12-48% as crack depth increases from 1-3mm

- Pulse factor provides superior fault detection sensitivity (0.82 correlation slope)

- 24th-order wheel polygonization triples cracked tooth contact forces (1178N vs. 392N)

- Mode I stress intensity factors dominate crack propagation ($K_I/K_{II} \approx 5$)

- J-integral increases linearly with crack length ($J \propto \epsilon^{1.02}$)

These results highlight the critical need for integrated vehicle-track-gear modeling in predicting gear failure progression and optimizing maintenance strategies for railway systems.