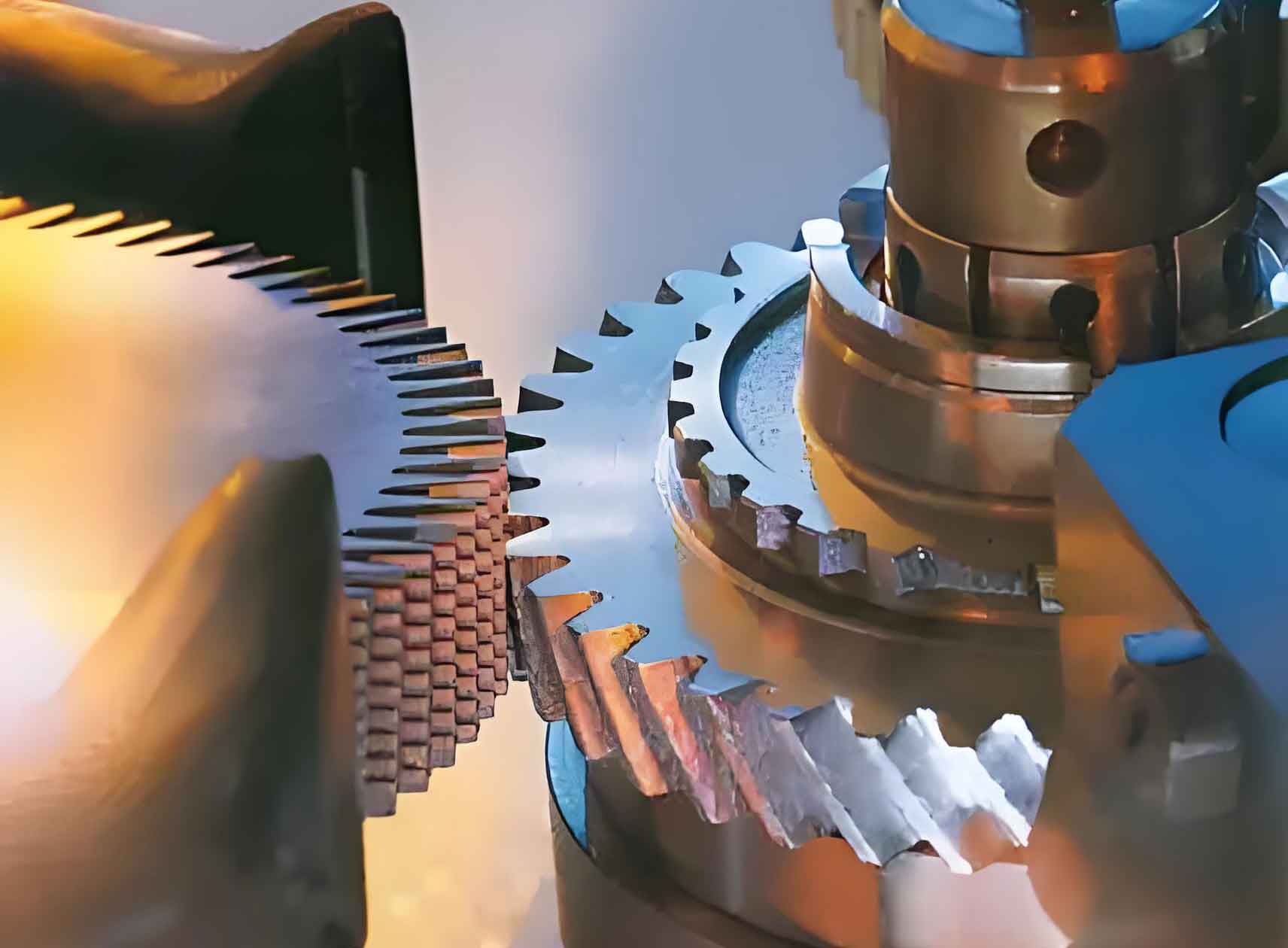

Gear shaving serves as a critical finishing process where post-shaving gear accuracy significantly impacts meshing noise and strength. Our investigation identified tooth surface distortion during gear shaving operations. This phenomenon manifests as twisted tooth surfaces, leading to two critical issues: (1) offset meshing points along the tooth width causing uneven load distribution and reduced gear strength, and (2) altered pressure angles affecting acoustic performance. To address this, we developed an experimental protocol isolating variables through single-factor testing, establishing correlations between process parameters and distortion magnitude. This empirical foundation enabled theoretical modeling of distortion mechanics, ultimately yielding effective countermeasures.

1. Problem Characterization

Post-shaving coordinate measurements revealed three-section distortion in helical gears. When translated into 3D models, the twisted surfaces exhibit progressive deviation along the tooth width. This distortion shifts meshing contact points toward one flank, generating asymmetric loading that accelerates fatigue failure. Simultaneously, pressure angle deviation occurs across different height sections, increasing NVH (Noise, Vibration, Harshness) during engagement. The combined effect compromises both durability and acoustic performance in transmission systems.

2. Distortion Factor Analysis

Potential variables influencing gear shaving distortion were systematically categorized and tested through controlled experiments. Each parameter was isolated while maintaining others constant, with distortion magnitude quantified via coordinate measuring machines (CMM). The experimental matrix examined:

| Tier 1 Factors | Tier 2 Factors | Testing Protocol |

|---|---|---|

| Tooling | Helix angle | Single-variable modulation with CMM validation |

| Profile modification | ||

| Crowning magnitude | ||

| Process | Axial vs radial method | Method comparison under fixed parameters |

| Cutting parameters | ||

| Equipment | Machine type | Cross-machine testing with identical tooling |

3. Experimental Procedure and Results

All trials used 20MnCr5 material gears with module 2.5, 30-tooth count, and 20° pressure angle. Distortion magnitude was measured as maximum flank deviation across three profile sections.

3.1 Tool Helix Angle Impact

Using identical cutting parameters (120 rpm, 0.5 mm/min feed) and machine, three tools with varying axis intersection angles were tested. Tool pre-inspection confirmed negligible initial distortion.

| Axis Intersection Angle (°) | Measured Distortion (μm) | Relationship |

|---|---|---|

| 10 | 15 | $$ \delta \propto \beta $$ |

| 12 | 20 | |

| 15 | 26 |

3.2 Machine Configuration Test

Identical gears were processed using three different shaving machines with equivalent cutting parameters and tooling:

| Machine Type | Distortion (μm) | Conclusion |

|---|---|---|

| CNC Shaver A | 24 | Negligible machine influence |

| CNC Shaver B | 23 | |

| Hydraulic Shaver C | 25 |

3.3 Shaving Method Comparison

Axial and radial gear shaving were compared using identical workpieces and tooling:

| Shaving Method | Distortion (μm) | Observation |

|---|---|---|

| Axial | ≤5 | Minimal distortion |

| Radial | 22-26 | Significant distortion |

3.4 Cutting Parameter Screening

Radial gear shaving trials with variable parameters showed no significant distortion correlation:

| Speed (rpm) | Feed (mm/min) | Distortion (μm) |

|---|---|---|

| 60 | 0.3 | 23 |

| 90 | 0.3 | 25 |

| 120 | 0.5 | 21 |

| 150 | 0.5 | 24 |

| 180 | 0.7 | 22 |

| 60 | 0.7 | 23 |

3.5 Profile Modification Effects

Tool crowning modifications were tested in radial gear shaving:

| Modification Type | Magnitude (μm) | Distortion (μm) | Correlation |

|---|---|---|---|

| Profile crowning | 10 | 22 | $$ \delta \propto C_v $$ |

| Profile crowning | 20 | 24 | |

| Lead crowning | 15 | 26 | Strong positive correlation |

| Lead crowning | 25 | 33 | |

| Lead crowning | 35 | 41 |

4. Experimental Conclusions

Radial gear shaving exclusively generates distortion, with two primary influencers: lead crowning magnitude (Cv) and tool axis intersection angle (β). Distortion magnitude follows the relationship:

$$ \delta = f(C_v, \beta) $$

where increased Cv or β elevates distortion. This occurs because radial gear shaving incorporates lead crowning, while axial methods do not. The kinematic differences between shaving methods explain this fundamental distinction.

5. Distortion Mechanism Analysis

Gear shaving utilizes crossed-axis helical gear kinematics where tool-workpiece axis intersection angle β generates sliding velocity:

$$ v_s = v_{t} \cdot \sin\beta $$

where vt is tangential velocity. This sliding action enables material removal. The axial sliding distance during full engagement is:

$$ a = P \cdot \tan\beta $$

where P is path of contact length. Crucially, when lead crowning exists, different axial tool sections remove varying material amounts. The tooth tip is cut by the tool root section, while the tooth root is cut by the tool tip section at axial distance a. For a tool with crowning radius r and gear width b, distortion δ is derived from circular crown geometry:

$$ (r – C_v + \delta)^2 + \left(\frac{b}{2}\right)^2 = \left(r + \frac{a}{2}\right)^2 $$

$$ (r – C_v)^2 + \left(\frac{b}{2}\right)^2 = r^2 $$

Solving these equations yields the distortion model:

$$ \delta = C_v \sqrt{\frac{4C_v^2 – b^2}{4C_v^2 – b^2 + 4P^2\tan^2\beta}} – C_v + \sqrt{r^2 – \left(\frac{b}{2}\right)^2} – \sqrt{r^2 – \left(\frac{b}{2}\right)^2 – P\cdot\tan\beta} $$

This confirms distortion increases with Cv, β, and b. The model enables predictive distortion calculation during process design.

6. Distortion Mitigation Strategy

Four solutions were evaluated based on the theoretical model:

| Option | Feasibility | Limitations |

|---|---|---|

| Switch to axial gear shaving | High | 50% productivity loss, higher cost |

| Eliminate lead crowning | Low | Compromises load distribution under torque |

| Reduce axis angle β | Medium | Impairs cutting efficiency and tool life |

| Compensatory tool grinding | High | Requires precise inverse distortion machining |

We implemented inverse distortion tool grinding by modifying CNC shaving cutter grinder kinematics. By introducing controlled eccentricity in the grinding wheel path, we generated pre-distorted tool profiles that counteract shaving distortion. The compensation magnitude follows:

$$ \delta_{comp} = -\delta(C_v, \beta) $$

Post-implementation measurements demonstrated significant improvement:

| Parameter | Pre-Compensation | Post-Compensation |

|---|---|---|

| Max distortion (μm) | 24-28 | 3-5 |

| Pressure angle deviation | 0.8-1.2° | ≤0.15° |

| Gear noise level | 78-82 dB | 72-74 dB |

7. Conclusion

Through systematic single-variable experimentation, we identified radial gear shaving distortion correlates primarily with lead crowning magnitude and axis intersection angle. Our theoretical model quantifies distortion as a function of gear width, crown geometry, and kinematic parameters. The inverse distortion tool grinding solution effectively compensates for these effects without sacrificing productivity or load distribution requirements. This comprehensive approach resolves tooth surface distortion in gear shaving processes, enhancing gear durability and acoustic performance in transmission systems. Future work will extend the model to multi-axis shaving configurations and hardened gear finishing applications.