This paper presents a novel modification method for internal gearing power honing, enabling the use of standard diamond dressing wheels to achieve flexible honing wheel dressing and produce high-precision modified gears. The method significantly reduces the cost and lead time associated with custom dressing tools, enhancing the versatility of gear honing processes.

1 Introduction

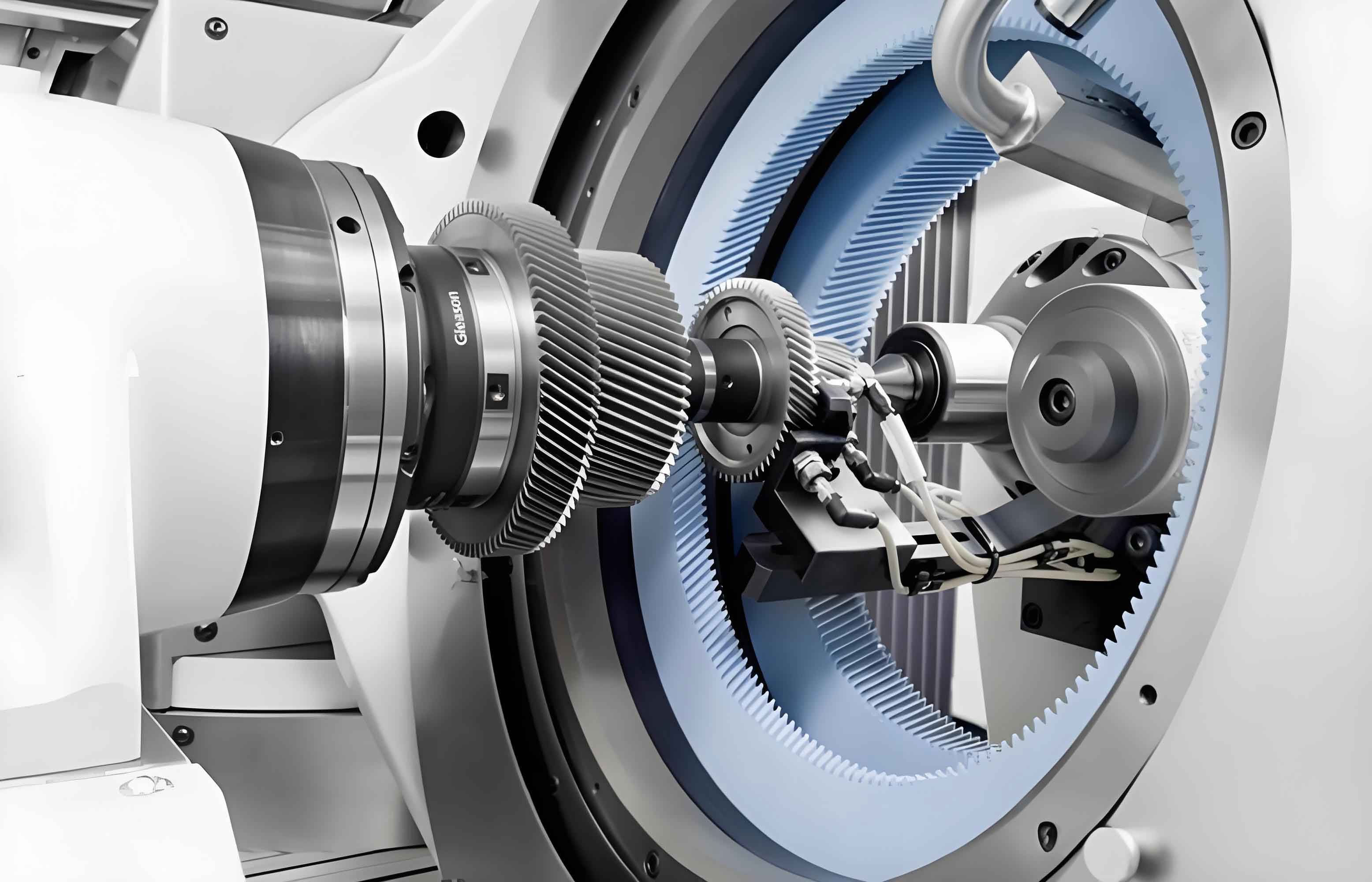

Gears are indispensable components in mechanical transmission systems, with ever-increasing quality demands. High-speed gears universally require tooth flank modifications to achieve high transmission accuracy, strength, and low noise. Internal gearing power honing is a high-efficiency finishing process offering advantages like superior surface roughness, high compressive residual stress, and noise-reducing surface textures. However, traditional honing requires workpiece-specific custom diamond dressing wheels for honing wheel preparation, increasing costs and development cycles. This research overcomes this limitation through flexible honing wheel dressing.

2 Mathematical Modeling of Internal Gearing Power Honing

The process comprises two stages: Honing wheel dressing and workpiece honing. Both involve spatial kinematics modeled using coordinate transformations and gear meshing theory.

2.1 Honing Wheel Dressing Model

The spatial relationship between the diamond dressing wheel (coordinate system \(S_s\)) and the honing wheel (system \(S_h\)) is defined by transformation matrices. The overall transformation \(M_{hs}\) integrates the relative motions:

$$ M_{hs}(F_z, \phi_s) = M_{h3} \cdot M_{32} \cdot M_{20} \cdot M_{01} \cdot M_{1s}(\phi_s) $$

where \(F_z\) is the axial feed, \(\phi_s\) is the dressing wheel rotation angle, \(\phi_h\) is the honing wheel rotation angle, \(z_s\) and \(z_h\) are tooth numbers, \(\alpha_{sh}\) is the center distance, and \(\beta_h\), \(r_{bh}\) are the honing wheel helix angle and base radius. The kinematic relationship is:

$$ \phi_h = \frac{z_s}{z_h} \phi_s \pm \frac{\tan \beta_h}{r_{bh}} F_z $$

The conjugate tooth surfaces satisfy the meshing equation:

$$ \frac{\partial \mathbf{r_1}}{\partial \phi_1} \cdot \mathbf{n} = 0 $$

Given the dressing wheel’s involute helicoid surface \(\mathbf{r_s}(\lambda, \theta)\) and normal vector \(\mathbf{n_s}(\lambda, \theta)\), the honing wheel surface point \(\mathbf{r_h}\) and normal \(\mathbf{n_h}\) after dressing are:

$$ \mathbf{r_h}(F_z, \phi_s, \lambda, \theta) = M_{hs}(F_z, \phi_s) \cdot \mathbf{r_s}(\lambda, \theta) $$

$$ \mathbf{n_h}(F_z, \phi_s, \lambda, \theta) = L_{hs}(F_z, \phi_s) \cdot \mathbf{n_s}(\lambda, \theta) $$

where \(L_{hs}\) is the rotational sub-matrix of \(M_{hs}\).

2.2 Workpiece Honing Model

Honing kinematics between the honing wheel (\(S_h\)) and workpiece (\(S_g\)) are modeled similarly. The transformation matrix \(M_{gh}\) is:

$$ M_{gh}(\phi_h) = M_{g1} \cdot M_{12} \cdot M_{2h}(\phi_h) $$

where \(\phi_g\) is the workpiece rotation angle, \(\Sigma_A\) is the theoretical shaft angle, and \(\alpha_{hg}\) is the honing center distance. The generated workpiece surface point \(\mathbf{r_g}\) and normal \(\mathbf{n_g}\) are:

$$ \mathbf{r_g}(F_z, \phi_h, \phi_s, \lambda, \theta) = M_{gh}(\phi_h) \cdot \mathbf{r_h}(F_z, \phi_s, \lambda, \theta) $$

$$ \mathbf{n_g}(F_z, \phi_h, \phi_s, \lambda, \theta) = L_{gh}(\phi_h) \cdot \mathbf{n_h}(F_z, \phi_s, \lambda, \theta) $$

3 Flexible Honing Wheel Dressing and Parameter Optimization

Flexible dressing introduces controlled multi-axis motions during honing wheel preparation. The axes include:

- Axial feed (\(F_z\)) of the dressing wheel along Z-axis.

- Radial feed (\(F_x\)) along A-axis.

- Dressing wheel rotation (\(\phi_2\)) about C2-axis.

- Honing wheel carrier rotations about A-axis (\(\Sigma_A\)) and B-axis (\(\Sigma_B\)).

- Honing wheel rotation (\(\phi_1\)) about C1-axis.

The motion parameters \(\Sigma_A\), \(\Sigma_B\), \(\alpha_{sh}\), and \(\phi_s\) are expressed as polynomials of \(F_z\):

$$ \alpha_{sh}(F_z) = \alpha_{sh0} + \sum_{k=1}^{4} a_k F_z^k $$

$$ \Sigma_A(F_z) = \Sigma_{A0} + \sum_{k=1}^{4} A_k F_z^k $$

$$ \Sigma_B(F_z) = \sum_{k=0}^{4} B_k F_z^k $$

$$ \phi_s(F_z, \phi_h) = c_0 + c_1 F_z + c_2 \phi_h + c_3 F_z^2 + c_4 F_z \phi_h + c_5 \phi_h^2 $$

This yields 21 polynomial coefficients \(\lambda_j (j=1,…,21)\) as design variables. The tooth flank is discretized into a 5×9 grid (45 points). The deviation between the actual honed flank and the target modification flank is quantified by the sum of normal deviations:

$$ f(\boldsymbol{\varepsilon}) = \sum_{i=1}^{45} (\Delta \mathbf{r}_i \cdot \mathbf{n}_i)^2 $$

A sensitivity matrix \(\mathbf{A}\) relates changes in coefficients \(\delta \lambda_j\) to changes in normal deviations \(\delta \varepsilon_i\) at each grid point:

$$ \{ \delta \varepsilon_i \} = \mathbf{A} \{ \delta \lambda_j \} = \left[ \frac{\partial \varepsilon_i}{\partial \lambda_j} \right] \{ \delta \lambda_j \} \quad (i=1,…,45; j=1,…,21) $$

An iterative optimization algorithm minimizes \(f(\boldsymbol{\varepsilon})\) using Newton’s method. The sensitivity matrix \(\mathbf{A}\) is typically ill-conditioned; its pseudo-inverse is computed via Singular Value Decomposition (SVD):

- Initialize coefficient vector \(\boldsymbol{\lambda}^{(0)}\).

- Calculate current deviation \(f(\boldsymbol{\varepsilon}^{(k)})\).

- Compute sensitivity matrix \(\mathbf{A}^{(k)}\) numerically by perturbing each \(\lambda_j\).

- Solve for coefficient update: \(\delta \boldsymbol{\lambda}^{(k)} = -\text{inv}[\mathbf{A}^{(k)}] \cdot \boldsymbol{\varepsilon}^{(k)}\) using SVD.

- Update coefficients: \(\boldsymbol{\lambda}^{(k+1)} = \boldsymbol{\lambda}^{(k)} + \delta \boldsymbol{\lambda}^{(k)}\).

- Repeat steps 2-5 until \(f(\boldsymbol{\varepsilon}^{(k)}) < \text{tolerance}\).

4 Numerical Simulation and Tooth Contact Analysis

A single-stage gear pair (Table 1) was analyzed under conditions: Input speed \(n_1 = 1500\) rpm, Power \(P = 45\) kW, with assumed assembly errors (50 µm parallel offset, 20 µm angular misalignment). KISSsoft software optimized the pinion flank modification (minimizing \(K_{H\beta}\) and \(\sigma_{Hmax}\)), yielding an optimal target flank with 8 µm profile crowning and 20 µm lead crowning.

| Parameter | Pinion | Gear |

|---|---|---|

| Number of teeth, \(z\) | 29 | 83 |

| Helix angle, \(\beta\) | 22° (LH) | 22° (RH) |

| Normal module, \(m_n\) (mm) | 1.65 | |

| Normal pressure angle, \(\alpha_n\) | 19° | |

| Face width, \(b\) (mm) | 24 | – |

Applying the optimization yielded the coefficients in Table 2. The flank deviation matrix \(\Sigma \Delta\) after optimization shows excellent agreement (maximum deviations ~0.03 µm).

| Coefficient | Value | Coefficient | Value |

|---|---|---|---|

| \(a_0\) | -0.003 | \(A_0\) | 0.0393 |

| \(a_1\) | 0.0027 | \(A_1\) | -0.0002 |

| \(a_2\) | 0.0001 | \(A_2\) | 0 |

| \(a_3\) | 0 | \(A_3\) | 0 |

| \(a_4\) | 0 | \(A_4\) | 0 |

| \(B_0\) | 0.0434 | \(c_0\) | 0.0152 |

| \(B_1\) | -0.0006 | \(c_1\) | 0.0040 |

| \(B_2\) | -0.0003 | \(c_2\) | 0.0010 |

| \(B_3\) | 0 | \(c_3\) | 0.0009 |

| \(B_4\) | 0 | \(c_4\) | 0 |

Tooth Contact Analysis (TCA) in KISSsoft compared the unmodified flank, target modified flank, and the flank produced by the optimized flexible gear honing process (Table 3). Contact patterns and stress distributions are shown below.

| Flank Type | Normal Load \(F_{n}\) (N/mm) | Contact Stress \(\sigma_{Hmax}\) (N/mm²) | Face Load Factor \(K_{H\beta}\) |

|---|---|---|---|

| Unmodified | 1781.54 | 2739.84 | 1.85 |

| Target Modification | 969.61 | 2223.12 | 1.04 |

| Flexible Honing Result | 1010.34 | 2231.81 | 1.04 |

The flexible honing process successfully replicated the target modification. Compared to the unmodified flank, the maximum normal load decreased by 43.3% and contact stress by 18.5%, while \(K_{H\beta}\) improved significantly from 1.85 to 1.04. The results from the flexible honing method are virtually identical to the target modification, confirming the method’s effectiveness in gear honing.

5 Conclusion

This research developed a flexible honing wheel dressing method for internal gear power honing, enabling the use of standard diamond dressing wheels to produce precisely modified gears. Key contributions are:

- A comprehensive mathematical model for honing wheel dressing and workpiece honing kinematics was established using coordinate transformations and gear meshing theory.

- Motion parameters during dressing (\(\Sigma_A\), \(\Sigma_B\), \(\alpha_{sh}\), \(\phi_s\)) were parameterized as polynomials of axial feed (\(F_z\)). A sensitivity matrix quantified the influence of 21 polynomial coefficients on the final workpiece flank topology.

- An SVD-based Newton iteration algorithm optimized the coefficients to minimize deviations between the simulated honed flank and the target modified flank.

- Numerical simulation and TCA on a gear pair demonstrated the method’s capability. The flexible honing process achieved flank modifications (8 µm profile, 20 µm lead crowning) nearly identical to the target, significantly improving load distribution (\(K_{H\beta} = 1.04\)) and reducing contact stress (18.5%) compared to the unmodified gear.

The method eliminates the need for custom diamond dressing wheels for each modified gear design, reducing the cost and lead time of precision gear honing. Future work will focus on experimental validation and extending the model to more complex modifications, further advancing the capabilities of gear honing technology.