Gears serve as foundational components across industries including automotive, aerospace, wind power, and robotics. The shift toward electric vehicles demands high-precision gears with superior noise suppression at high rotational speeds. Internal gear power honing excels in this context, offering exceptional accuracy, surface error correction, and enhanced transmission performance. This process utilizes an internal honing wheel—an abrasive-laden formed gear—to refine workpiece gears through controlled meshing. This paper develops a dedicated database system for internal gear power honing to streamline process data management, generate optimized machining solutions, and elevate production efficiency and quality.

Research on Internal Gear Power Honing Process

Basic Principles

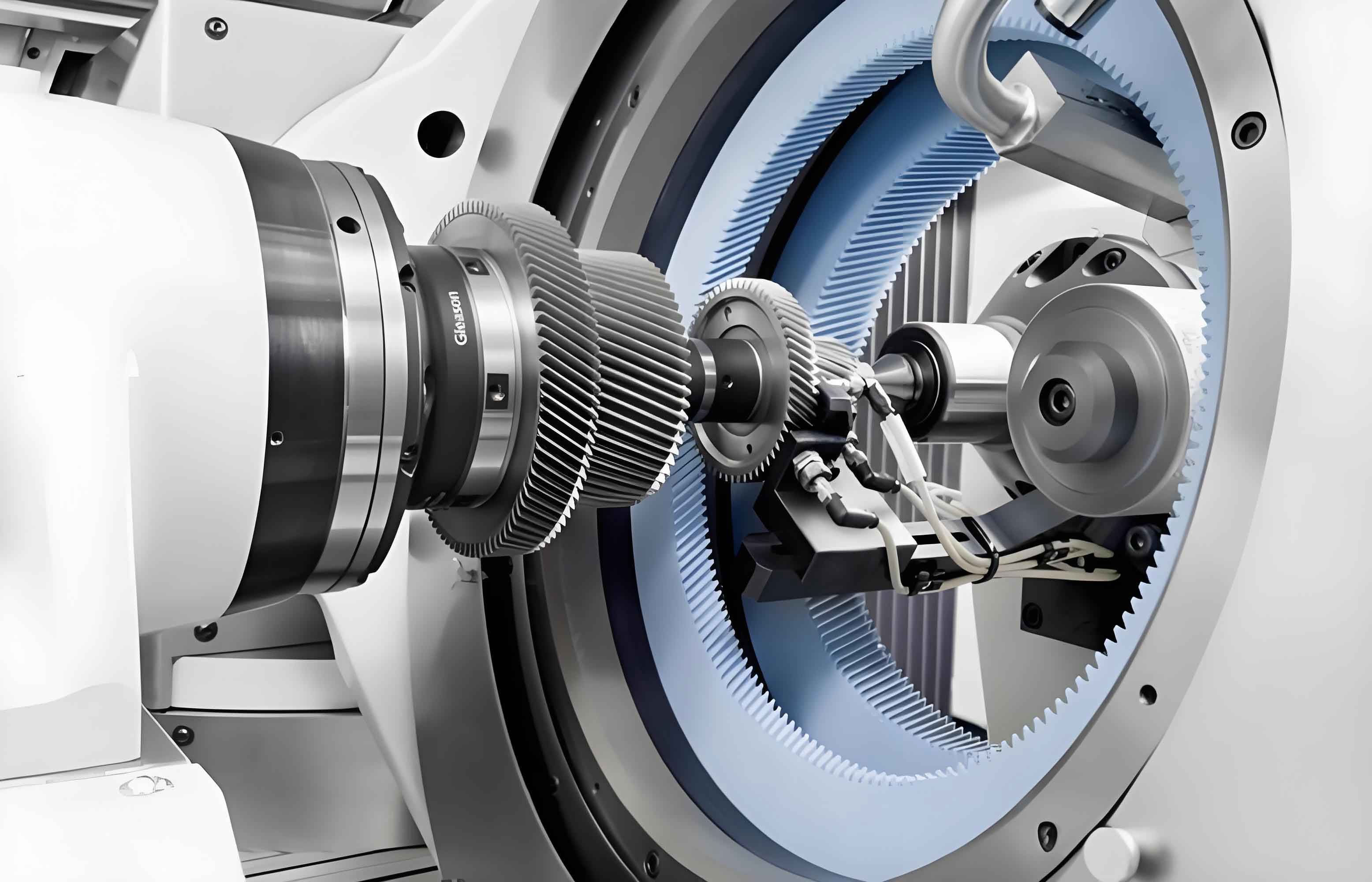

Internal gear power honing employs a formed internal helical gear-shaped honing wheel coated with abrasives (e.g., diamond, CBN, or alumina) bonded in ceramic, resin, or metal matrices. The workpiece gear and honing wheel engage under electronic gearbox control, simulating crossed-axis helical gear meshing. Relative sliding between surfaces enables abrasive grains to remove micron-level material. Radial feed motion progressively engages grains, while axial oscillation ensures uniform wheel wear.

Material removal occurs in three stages per abrasive grain: sliding (elastic deformation), plowing (plastic deformation without chip formation), and cutting (material removal as chips). Residual compressive stresses induced during honing enhance fatigue strength. This process achieves DIN 6-grade accuracy with typical overlap ratios exceeding 2, ensuring stable contact pressure.

Motion Forms of Honing Machine

Modern honing machines, like the Fassler HMX-400, feature seven axes:

- C1: Honing wheel rotation (0–6,000 rpm)

- C2: Workpiece rotation (0–1,500 rpm)

- X: Radial feed (185 mm stroke)

- Z1: Axial oscillation (500 mm stroke)

- Z2: Workpiece axial adjustment

- A: Shaft angle adjustment (±45°)

- B: Crowning motion (±10°)

Electronic synchronization between C1 and C2 maintains forced meshing, minimizing flank deviations.

Honing Wheel Feeding Methods

Three feeding strategies govern material removal:

- Direct Infeed: Only radial feed (X-axis). Fastest but causes uneven wheel wear.

- Incremental Infeed: Radial feed with intermittent axial oscillation (Z1-axis). Balances speed and surface quality.

- Continuous Infeed: Synchronized radial feed and axial oscillation. Delivers high surface quality but requires complex 4-axis interpolation.

| Method | Efficiency | Surface Quality | Wheel Wear | Wheel Life |

|---|---|---|---|---|

| Direct Infeed | Highest | Moderate | Severe | Low |

| Incremental Infeed | Moderate | Highest | Low | High |

| Continuous Infeed | High | High | Low | High |

Honing Wheel Feeding Control Strategies

Two control paradigms regulate radial infeed:

- Position Control: Fixed stepwise radial displacement. Simple but causes rising honing force due to elastic deflections, risking surface burns.

- Force Control: Real-time force sensors adjust feed steps to maintain constant honing force. Enhances stability and surface finish but increases system complexity.

Experimental data confirms force control’s superiority in surface integrity:

$$R_a (\mu m)_{\text{Force Control}} = 0.32 \pm 0.04, \quad R_a (\mu m)_{\text{Position Control}} = 0.48 \pm 0.07$$

$$R_{pk} (\mu m)_{\text{Force Control}} = 0.18 \pm 0.03, \quad R_{pk} (\mu m)_{\text{Position Control}} = 0.29 \pm 0.05$$

Honing Wheel Dressing Process

Diamond dressing tools (DDR for tip, DDG for profile) regenerate worn wheels. Axis angle (A) and center distance compensate for geometric shifts during dressing. Post-dressing tool offsets ensure consistent honing results without parameter recalibration.

Overall Design of Gear Honing Process Database System

Requirement Analysis

The system manages non-controlled variables (gear geometry, material), controlled variables (wheel specs, coolant), process parameters (force, temperature), and output metrics (roughness, accuracy). Functional requirements include:

- Basic data management (workpiece, wheel, machine, coolant)

- Process instance storage and retrieval

- Hybrid reasoning for parameter recommendation

- User role-based access control

- Data sharing/backup

Conceptual and Logical Design

Entity-Relationship (E-R) modeling defined core entities: Honing_Parameters, Honing_Wheel, Workpiece_Gear, Machine, and Coolant. Relationships enable multi-attribute queries, e.g., matching wheel specs to gear materials. The logical schema converted E-R models into SQL Server tables:

| Attribute | Data Type | Size |

|---|---|---|

| Wheel_ID | INT | 8 |

| Teeth_Number | INT | 8 |

| Abrasive_Type | NVARCHAR | 20 |

| Bond_Type | NVARCHAR | 20 |

System Architecture

A hybrid C/S and B/S architecture balances functionality and accessibility:

- C/S Client: Installed on shop-floor machines for parameter optimization and data entry.

- B/S Web Interface: Enables remote data query and basic management via browsers.

- Application Server: Hosts SQL Server 2012 and handles computation-intensive tasks (e.g., optimization algorithms).

This structure supports future cloud integration while accommodating real-time shop-floor needs.

Application of Hybrid Reasoning Technology and Honing Parameter Optimization

Hybrid Reasoning Implementation

The system combines Case-Based Reasoning (CBR) and Rule-Based Reasoning (RBR):

- RBR Preprocessing: Rules from manuals filter feasible solutions, e.g.,

$$ \texttt{IF Gear\_Module} > 4\ \texttt{mm THEN Feed\_Rate} \leq 8\ \mu \texttt{m/s} $$ - CBR Retrieval: Nearest-neighbor search computes similarity between query case $Q$ and historical cases $P$:

$$ \text{sim}(P,Q) = \frac{ \sum_{i=1}^{n} \omega_i \cdot \text{sim}_{\text{local}}(p_i, q_i) }{ \sum_{i=1}^{n} \omega_i } $$

Weights $\omega_i$ prioritize critical attributes (material: $\omega=8$, module: $\omega=2$, helix angle: $\omega=1$). Local similarities for categorical data (e.g., abrasive types) use predefined matrices. A similarity threshold of 0.75 ensures relevant matches.

Honing Parameter Optimization

Response Surface Methodology (RSM) models honing force $F_x$ for 20CrMnTi gears:

$$ F_x = 45.8 – 0.0159n_2 + 0.0661f_z + 25.842f_x + 2.42857 \times 10^{-4}n_2^2 – 0.01216f_z^2 – 0.2619f_x^2 + 2.7 \times 10^{-4}n_2f_z – 3.9285n_2f_x – 0.03611f_zf_x $$

A Particle Swarm Optimization with Genetic traits (PSOG) minimizes $F_x$:

- Initialize particles with position $\mathbf{x}_i$ and velocity $\mathbf{v}_i$.

- Update using cognitive/social terms:

$$ \mathbf{v}_i^{(t+1)} = \mathbf{v}_i^{(t)} + c_1 r_1 (\mathbf{p}_i – \mathbf{x}_i^{(t)}) + c_2 r_2 (\mathbf{p}_g – \mathbf{x}_i^{(t)}) $$

$$ \mathbf{x}_i^{(t+1)} = \mathbf{x}_i^{(t)} + \mathbf{v}_i^{(t+1)} $$ - Apply genetic mutation:

$$ \mathbf{x}_i’ = \mathbf{p}_g + \mu (\mathbf{x}_{s1} – \mathbf{x}_{s2}) $$ - Recombine via stochastic crossover.

PSOG outperformed standard PSO in convergence speed and precision for a 20-dimensional test function. For honing force minimization, it achieved:

$$ \min F_x = 77.3\ \text{N}\ \text{at}\ (n_2=1780\ \text{rpm},\ f_x=70\ \text{mm/min},\ f_z=5.5\ \mu \text{m/s}) $$

Development of Gear Honing Process Database System

Application Client

Built with MFC/C++ in Visual Studio 2010, the client uses ADO for SQL Server connectivity. Key interfaces include:

- Login: Role-based access (operator, admin, super-admin).

- Data Management: CRUD operations for gears, wheels, and process instances.

- Hybrid Reasoning: Input gear parameters to retrieve/optimize honing recipes.

ADO connection workflow:

_bstr_t strConnect = "Driver={SQL Server};Server=IP;Database=honing_db;";

m_pConnection->Open(strConnect, "user", "pass", adConnectUnspecified);Web Front-end

PHP/HTML-based portal supports remote access. Features include:

- Process knowledge base (machines, coolants, honing principles).

- AJAX-driven instance management with JSON responses.

- Role-centric views (e.g., operators query data; admins edit wheel specs).

User authentication snippet:

$query = "SELECT * FROM users WHERE user_name='$username'";

if(password_verify($password, $db_hash)) {

$_SESSION['role'] = $row['role'];

}Conclusion and Outlook

This research developed a dedicated database system for internal gear power honing, integrating process management, hybrid reasoning, and parameter optimization. Key contributions include:

- Mechanistic analysis of honing dynamics (feeding strategies, force control).

- Hybrid CBR-RBR framework with weighted similarity metrics.

- PSOG-based honing parameter optimization validated experimentally.

- Deployable C/S and B/S interfaces for shop-floor and remote access.

Future work will focus on refining weight assignment in CBR via sensitivity analysis, developing physics-based honing models, and integrating the database with CNC systems for real-time adaptive control. Expanding the honing instance repository remains critical for enhancing recommendation accuracy.