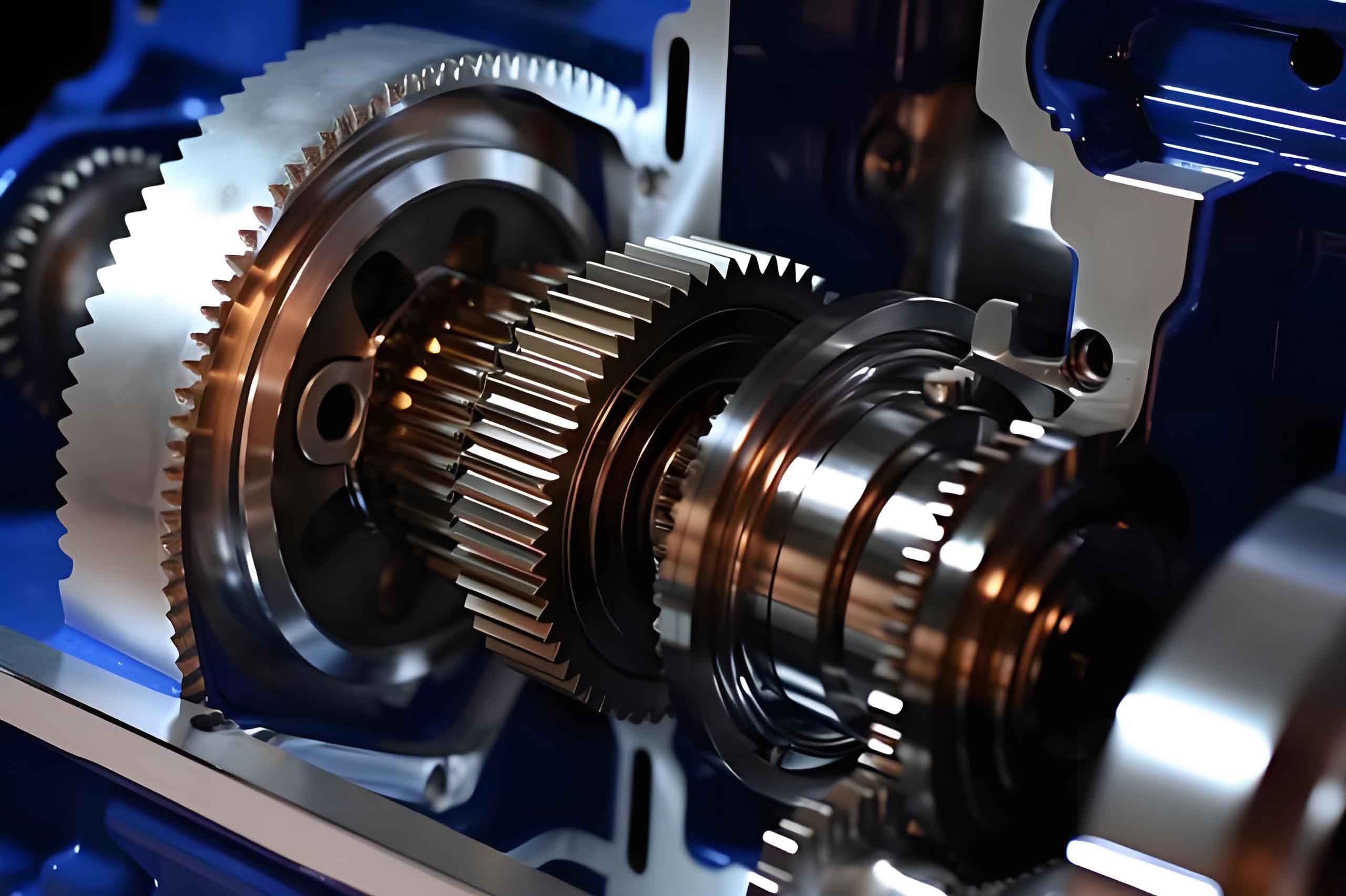

Automotive gears are critical transmission components responsible for transferring power and altering speed and direction. Operating under complex conditions—enduring significant loads, frequent impacts at tooth roots, and substantial surface friction—they demand exceptional wear resistance, high contact fatigue strength, and bending fatigue resistance. The performance and longevity of automotive gears heavily depend on material selection and heat treatment. While materials range from forged/cast steels to non-metallics, carburized steels dominate. This article explores performance requirements, material advancements, and future trends for automotive gear steels.

Performance Requirements for Automotive Gear Steel

Beyond standard strength and toughness, automotive gear steels require three core characteristics: controlled hardenability (narrow bandwidth), high purity, and fine grain size. Machinability (hot/cold workability and chip-breaking) is also essential.

1. Hardenability

Hardenability dictates post-carburizing core strength. Precise control of C, Cr, Mn, and Mo ensures consistent quenching response. Hardenability bandwidth ($$\Delta J$$) critically affects post-heat-treatment dimensional stability. Modern secondary refining and continuous casting enable precise prediction via computational models:

$$ J = k \cdot [C]^a \cdot [Cr]^b \cdot [Mn]^c \cdot [Mo]^d $$

where \(k\), \(a\), \(b\), \(c\), \(d\) are alloy-specific coefficients.

| Gear Type | Required Jominy Distance (HRC 40) | Typical Steel Grades |

|---|---|---|

| Passenger Car Transmission | 10 – 20 mm | 20MnCr5, SCM420H |

| Heavy-Duty Axle | 25 – 40 mm | 20CrNi2Mo, 17CrNiMo6 |

2. Purity

Oxide/sulfide inclusions and trace elements (N, H, O, S) degrade fatigue performance. Oxygen content (\([O]\)) directly influences contact fatigue strength (\(\sigma_{cf}\)):

$$ \sigma_{cf} \propto \frac{1}{\sqrt{[O]}} $$

Reducing \([O]\) from 45 ppm to 20 ppm can increase \(\sigma_{cf}\) by 47%. Ti is restricted (<0.01%) to avoid harmful TiCN precipitates.

3. Grain Size

Fine, stable austenite grains (ASTM 5-8) minimize distortion and enhance fracture resistance. Grain growth during vacuum carburizing is mitigated via Al/Nb additions:

$$ d^{-1/2} = k_1 + k_2 \cdot t^{-1/2} $$

where \(d\) is grain size, \(t\) is time, and \(k_1\), \(k_2\) are constants. Optimal Al (0.020–0.055%) and N (0.010–0.018%) ratios are critical.

4. Machinability

Automated automotive gear production demands superior chip-breaking. Controlled sulfur content (0.020–0.035%) improves machinability. Lead-free alternatives (Bi, Mg, Ca) are emerging. Avoiding granular bainite post-forging enhances tool life.

Current Materials for Automotive Gears

1. Carburizing Steels

Low-alloy steels dominate:

- Mn-Cr Series (e.g., 20MnCr5): Cost-effective for transmissions.

- Cr-Mo Series (e.g., SCM420H): Balanced strength/toughness.

- Cr-Ni-Mo Series (e.g., SAE8620): High-load axles.

2. Air-Cooled Bainitic Steels

Non-quenched steels like FB1 offer energy savings and reduced distortion. Key advantages:

$$ \sigma_{TS} \geq 1200 \text{ MPa}, \quad K_{IC} \geq 90 \text{ MPa·m}^{1/2} $$

Applications: Precision passenger car gears requiring minimal post-machining.

3. Meta-Bainitic Steels

Developed steels (e.g., BZ18Q) feature bainite/ferrite/retained austenite microstructures. Their carburizing response rivals Ni-rich alloys:

$$ \text{Surface Hardness} = 60 – 65 \text{ HRC}, \quad \text{Core Toughness} = 100 – 120 \text{ J} $$

4. Austempered Ductile Iron (ADI)

ADI provides vibration damping and high specific strength. For truck gears:

$$ \sigma_{cf} \approx 1600 \text{ MPa}, \quad \mu (\text{Friction Coefficient}) \leq 0.1 $$

Though bending fatigue strength lags behind carburized steels, new Mn-Cu ADI grades show promise for spiral bevel automotive gears.

Development Trends

1. Narrow Hardenability Bandwidth

Targeting \(\Delta J \leq 4 \text{ HRC}\) at critical Jominy positions. Achieved via:

- Computer-aided composition control (NCC)

- Dynamic secondary refining adjustments

2. High-Toughness Case

Optimizing for impact resistance:

$$ K_{IC}^{case} \propto [\text{Ni}]^{0.5} \cdot [\text{Mo}]^{0.3} / [\text{Si}] $$

Low-Si (<0.10%), low-P (<0.015%), and ultra-low oxygen (<10 ppm) steels are essential.

3. Enhanced Machinability

Sulfide morphology control through:

$$ \text{Mn/S} \geq 20, \quad \text{Ca Treatment} \rightarrow \text{Globular MnS} $$

Development of Pb-free, Bi/Ca-modified grades.

4. Lightweight Materials

Metal matrix composites (MMCs) for weight reduction:

$$ \rho_{composite} = \rho_m (1 – V_f) + \rho_f V_f $$

| Material | Density (g/cm³) | Specific Strength (MPa·cm³/g) |

|---|---|---|

| 20MnCr5 Steel | 7.85 | 51.0 |

| Al-SiC MMC (30% vol.) | 2.96 | 67.5 |

Conclusion

Advancements in automotive gear steels focus on:

- Narrow-hardenability alloys (e.g., 28MnCr5, 20CrNiMo) for distortion control.

- High-purity melts ([O] ≤ 15 ppm, [Ti] ≤ 0.01%) to extend fatigue life.

- Machinable variants with optimized S/Ca ratios for high-speed CNC.

- Lightweight alternatives like ADI and MMCs for electrified vehicles.

Future automotive gear materials will integrate computational alloy design, Industry 4.0 process control, and sustainable manufacturing—balancing performance, cost, and environmental impact.