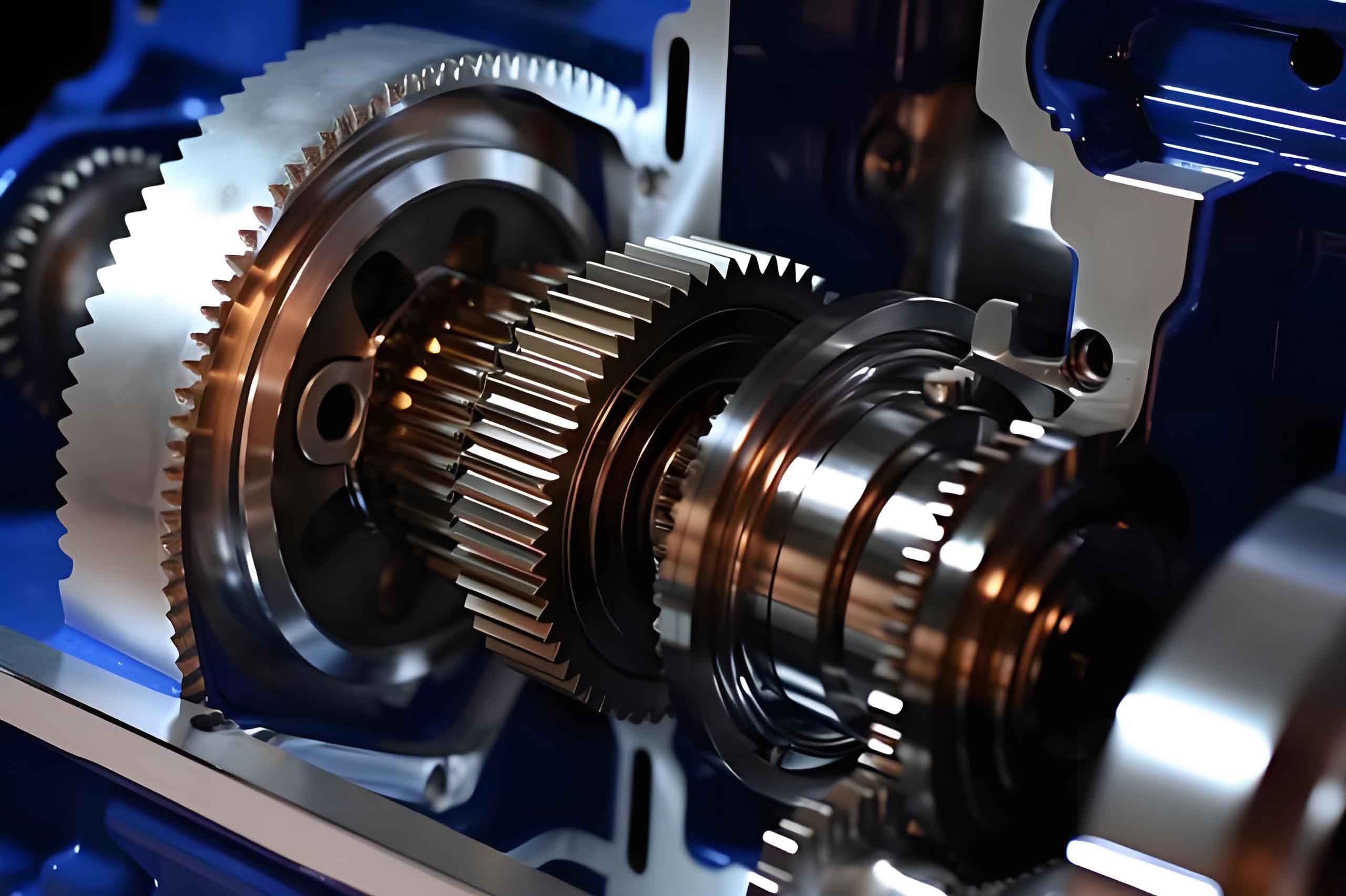

Automotive gears are critical components in vehicle transmission systems, where grinding cracks pose significant reliability risks. These defects exhibit characteristics like shallow depth, short length, and low detectability. Multi-optical path conditions further complicate crack identification due to diverse imaging geometries and complex light interactions. This work presents a machine vision-based approach for robust crack recognition in automotive gears under such challenging conditions.

The imaging system employs a CCD industrial camera with 5mm focal length, F2.1 aperture, and ring-shaped LED illumination positioned within 20mm of the optical axis. Image resolution is standardized at 100×300 pixels to maintain consistency. The acquisition setup minimizes optical interference while capturing detailed surface characteristics:

Preprocessing begins with Gaussian spatial filtering to eliminate high-frequency noise while preserving crack morphology. The filter operates in 2D space as:

$$G(m,n) = \frac{1}{2\pi\delta^2} e^{-\frac{(i^2 + j^2)}{2\delta^2}}$$

where $\delta$ denotes Gaussian variance. Residual impurities are removed through information entropy calibration:

$$P(m,n) = \frac{\sum_{s=0}^{200} \sum_{v=0}^{200} r \cdot h}{\log_2(m \cdot n)}$$

Grayscale conversion follows using single-component weighting and threshold shearing. Color channels are weighted by:

$$k(x,y) = 1.3R + 1.692G + 14B$$

Shearing continues iteratively until color saturation $r=0$:

$$S = \sum_{r=0}^{\lambda} \frac{w \cdot r^2}{x}$$

Feature extraction utilizes 3D vision sensors to segment images into gear body ($\Omega_b$), auxiliary components ($\Omega_a$), and background ($\Omega_{bg}$). Segmentation thresholds are determined by histogram peak similarity:

$$E = \alpha(X_0 + X_e) / 2$$

with optimal partitioning achieved through:

$$U(i,j) = \sum_{k=1}^{n} A_l \cdot [k \cdot E(i,j,k)]$$

Three feature classes are extracted from segmented regions:

Shape features via bidirectional projections:

$$V = \frac{\theta}{4\pi} \left( \int_{p=1}^{m} X_p(w,t) dp + \int_{r=1}^{n} Y_r(w,t) dr \right)$$

Density features using non-stationary filtering:

$$D = \eta \sum_{u \in [0,1]} V_u \cdot d_u$$

Area features through boundary expansion:

$$I = \lambda(D_u / 2 + L_o)$$

Recognition employs Support Vector Machines with particle swarm optimization. Feature weights are optimized in $k$-dimensional space:

$$\min_{f \in S} \sum_{k=1}^{n} \| f(k) – s_k \|^2$$

Classification is performed using the decision function:

$$G_{SVM} = \text{sgn} \left[ \sum_{k=1}^{n} \alpha_i \beta_j \cdot S(i,j) \cdot C \right]$$

Experimental validation used 600 automotive gear images with hardware configuration: 64GHz CPU, 128GB RAM, and MATLAB R2019b. Performance comparisons against established methods demonstrate superiority:

| Method | Initial Accuracy | Noisy Accuracy | Fault Tolerance |

|---|---|---|---|

| Proposed | 95.6% | 96.8% | 97.3% |

| Reference [4] | 94.3% | 94.9% | 95.7% |

| Reference [5] | 95.4% | 96.1% | 96.8% |

Recognition efficiency was evaluated across image batches:

| Image Count | Proposed (s) | Ref [4] (s) | Ref [5] (s) |

|---|---|---|---|

| 100 | 0.8 | 1.2 | 1.5 |

| 300 | 2.1 | 3.8 | 4.3 |

| 600 | 4.0 | 7.2 | 8.1 |

For automotive gear quality control, this method demonstrates significant advantages in multi-optical environments. The integration of 3D segmentation with optimized SVM classification achieves 40% faster processing than comparative techniques while maintaining 97.3% fault tolerance. Future work will extend this framework to other drivetrain components like bearing surfaces and spline shafts.