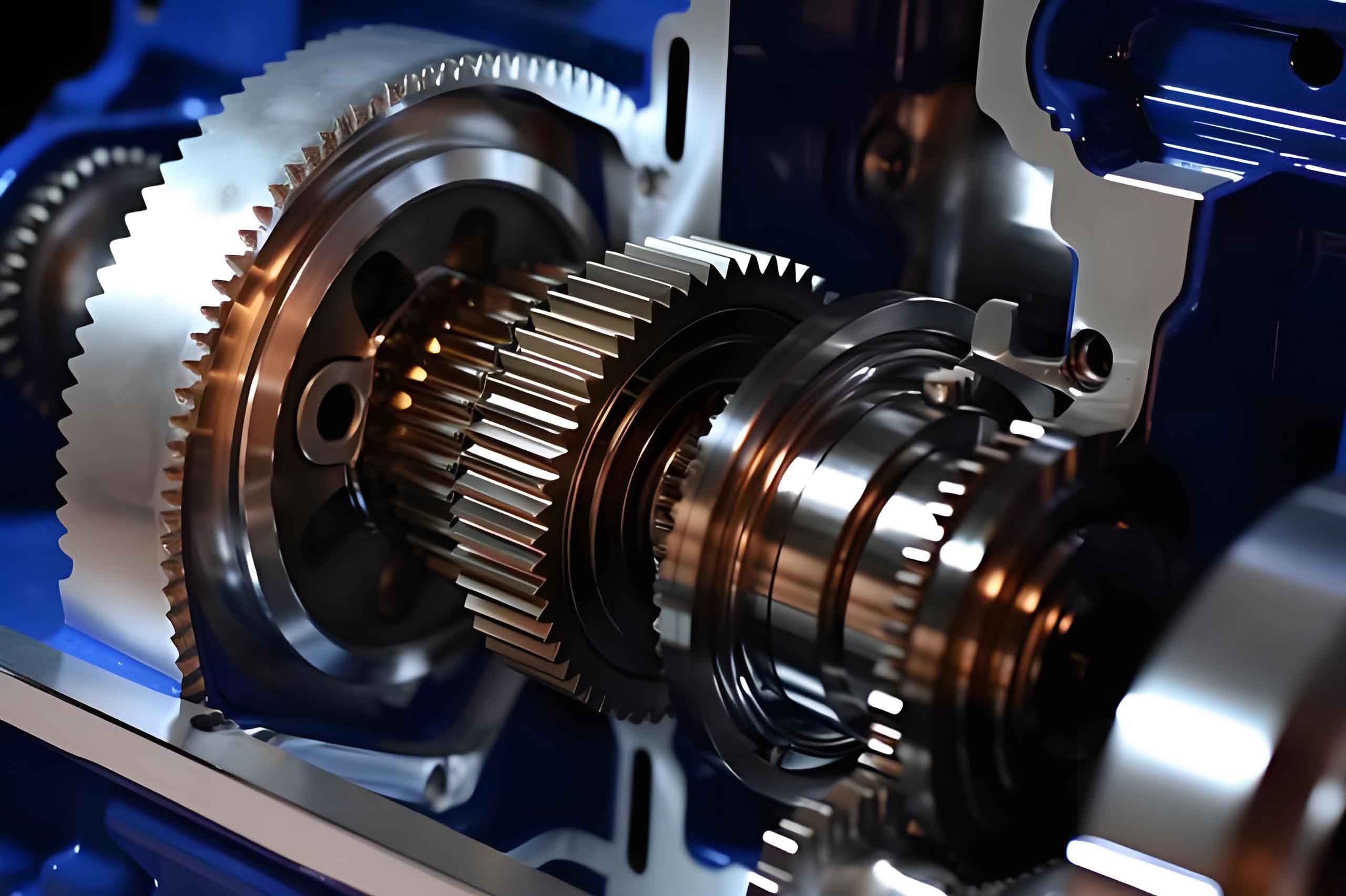

In automotive manufacturing, the quality of gears – critical components in transmission systems – directly impacts vehicle functionality and reliability. Material selection and heat treatment processes primarily determine automotive gear quality, with heat treatment dictating essential performance characteristics that affect service life. Common heat treatments include normalizing and isothermal annealing for pre-treatment, alongside post-forging thermochemical processes. While significant research optimizes automotive gear materials and heat treatments, studies on corrosion resistance remain limited. This work comprehensively analyzes how normalizing versus isothermal annealing influences the corrosion performance of 20MnCr5 automotive gear steel in NaCl environments.

Experimental Methodology

Automotive gear specimens were prepared from 20MnCr5 steel, with chemical composition verified by energy-dispersive X-ray fluorescence (Table 1). Post-forging at 1200°C, samples underwent either normalizing (940°C/1h, air cooling) or isothermal annealing (940°C/0.5h → 630°C/1h, air cooling). Corrosion behavior was evaluated through three methods:

Salt Spray Testing: Specimens (2cm×1cm×0.5cm) were exposed to 3.5wt% NaCl fog (23±1°C, 0.75±0.05MPa) at 25° inclination for 72h. Surface morphology was analyzed using optical microscopy.

Immersion Testing: Samples underwent full immersion in 0.6mol/L NaCl solution for 240h. Mass loss was measured every 12h using precision electronic balances. Corrosion rate was calculated as:

$$CR = \frac{K \times W}{A \times T \times \rho}$$

Where \(CR\) = corrosion rate (mm/year), \(K\) = constant (8.76×10⁴), \(W\) = mass loss (g), \(A\) = area (cm²), \(T\) = time (h), and \(\rho\) = density (g/cm³).

Electrochemical Testing: Using a three-electrode system (Pt counter electrode, saturated calomel reference electrode) in 0.6mol/L NaCl, potentiodynamic polarization occurred at 0.001V/s after 180s stabilization at -1.0V. Corrosion current density (\(i_{corr}\)) and potential (\(E_{corr}\)) were derived from Tafel extrapolation using:

$$\log i = \frac{E – E_{corr}}{\beta_a} \quad \text{(anodic branch)}$$

$$\log i = \frac{E_{corr} – E}{\beta_c} \quad \text{(cathodic branch)}$$

| Element | C | Mn | Cr | Si | S | Al |

|---|---|---|---|---|---|---|

| Specification | 0.17-0.22 | 1.0-1.3 | 1.0-1.3 | 0.1-0.35 | 0.02-0.035 | 0.02-0.055 |

| Measured | 0.205 | 1.120 | 1.125 | 0.102 | 0.024 | 0.024 |

Results and Discussion

Salt spray testing revealed stark differences: normalized automotive gears exhibited extensive pitting corrosion with expansive pits and white corrosion products, while isothermally annealed gears showed minimal micro-pitting. This divergence originates from microstructural heterogeneity in normalized steel versus the homogeneous structure achieved through isothermal transformation at 630°C. Uniform microstructures in automotive gear components create consistent electrochemical properties, reducing localized corrosion susceptibility.

Immersion testing quantified corrosion kinetics (Table 2). Normalized automotive gears demonstrated rapid initial mass loss, reaching 1.02% after 240h. The corrosion rate followed a parabolic growth model:

$$W^2 = k_p \cdot t$$

Where \(W\) = mass loss, \(k_p\) = parabolic rate constant, and \(t\) = time. In contrast, isothermally annealed gears exhibited 80% lower mass loss (0.20%), adhering to logarithmic kinetics:

$$W = k_l \cdot \log t + C$$

This indicates stable passivation behavior in annealed automotive gear components.

| Parameter | Normalized | Isothermal Annealed |

|---|---|---|

| Mass Loss (240h) | 1.02% | 0.20% |

| Corrosion Potential (Ecorr) | -1.032 V | -0.115 V |

| Corrosion Current Density (icorr) | 18.7 μA/cm² | 2.3 μA/cm² |

| Pitting Density | 127/cm² | 9/cm² |

| Dominant Kinetics | Parabolic | Logarithmic |

Electrochemical polarization confirmed these trends. Normalized automotive gear steel exhibited active dissolution with \(E_{corr} = -1.032V\) and \(i_{corr} = 18.7 \mu A/cm^2\). Annealed specimens demonstrated nobler behavior (\(E_{corr} = -0.115V\)) with significantly lower \(i_{corr} (2.3 \mu A/cm^2)\). The polarization resistance (\(R_p\)) was calculated using:

$$R_p = \frac{\beta_a \beta_c}{2.303 \cdot i_{corr} (\beta_a + \beta_c)}$$

Revealing 8.2× higher \(R_p\) for annealed automotive gears, confirming superior corrosion resistance. Microstructural analysis attributes this to carbide distribution homogeneity and reduced galvanic couples in annealed specimens.

Conclusions

1. Normalized 20MnCr5 automotive gear steel exhibits severe pitting corrosion in NaCl environments due to microstructural heterogeneity, with mass loss reaching 1.02% after 240h immersion

2. Isothermal annealing enhances automotive gear corrosion resistance by 80%, limiting mass loss to 0.20% through homogeneous microstructure development

3. Electrochemical parameters confirm superior performance: annealed automotive gears demonstrate 760mV nobler corrosion potential and 88% lower corrosion current density versus normalized counterparts

4. The corrosion kinetics transition from parabolic (normalized) to logarithmic (annealed), indicating stable passivation behavior in optimally heat-treated automotive gear components

5. Isothermal annealing is recommended for critical automotive gear applications where corrosion resistance impacts functional reliability and service life