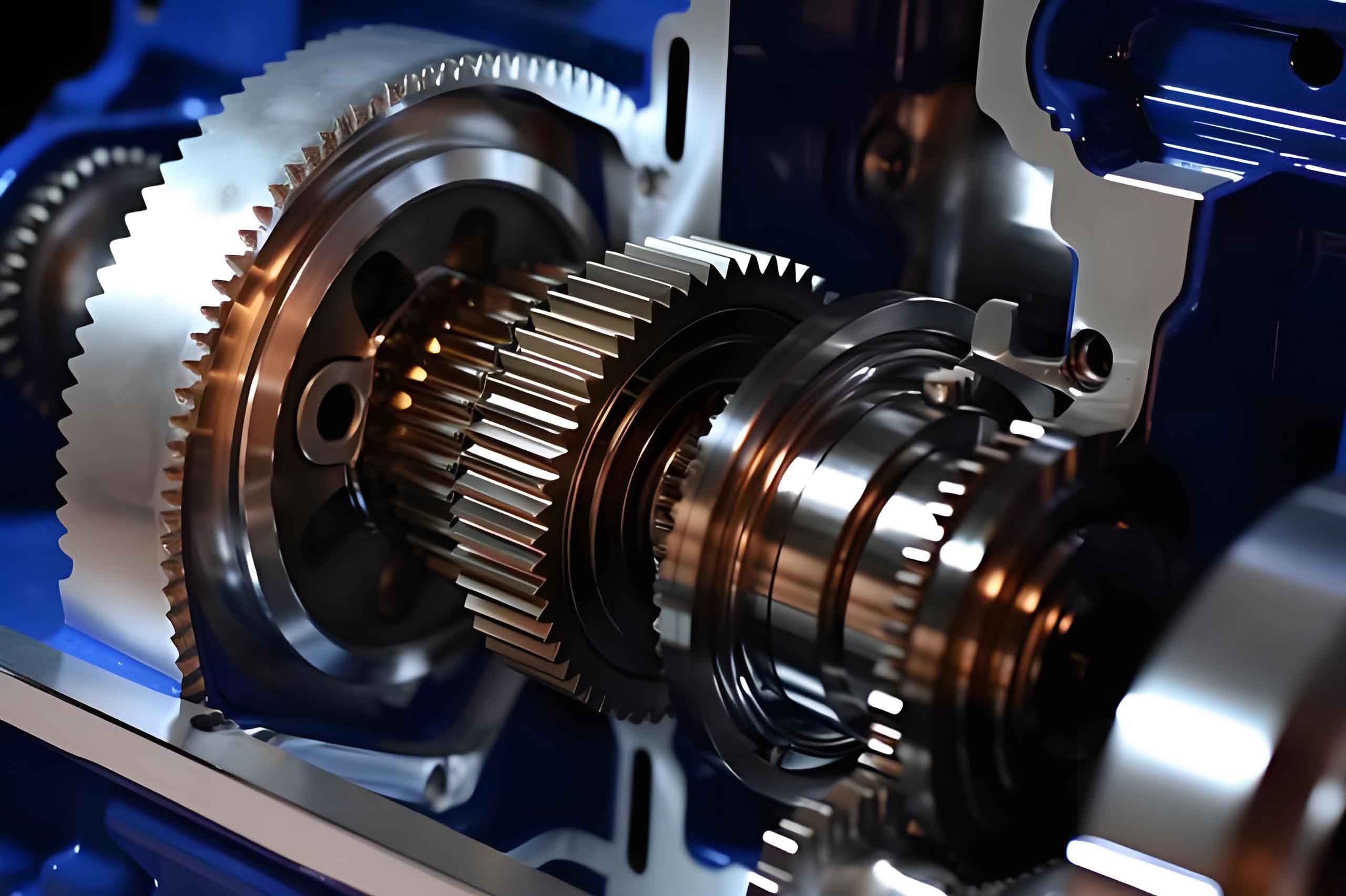

Over the past decade, advancements in testing technologies have significantly propelled the development of China’s automotive industry test equipment. Breakthroughs in drive/load technology, control systems, sensor accuracy, and data analytics now enable comprehensive validation of automotive gear transmission systems. As Principal Engineer at China Academy of Machinery Science & Technology, I’ve witnessed this evolution firsthand. This article details key testing methodologies and emerging equipment trends critical for next-generation transmission development.

Development Testing: Foundational Validation

Development testing validates design integrity and manufacturing robustness before mass production. For automotive gear systems, this encompasses bench tests (durability, performance) and vehicle tests. Bench testing identifies failures early, while vehicle testing confirms real-world reliability. Crucially, performance tests reduce costly durability test iterations.

| Test Category | Purpose | Impact on Durability Pass Rate |

|---|---|---|

| Durability (e.g., Full Transmission Endurance) | Validates gear/bearing lifecycle under simulated loads | Direct validation (4–6 months/test) |

| Performance (Contact Pattern, Lubrication, NVH) | Diagnoses meshing defects, lubrication efficiency, noise sources | Increases pass rate by 30–50% |

Contact pattern testing evaluates gear mesh alignment under load, preventing skewed load distribution and premature failure. The core equation for contact stress (σH) highlights its criticality:

$$ \sigma_H = Z_E \sqrt{\frac{F_t K_A K_v K_{H\beta} K_{H\alpha}}{b_w d_1} \cdot \frac{u+1}{u}} $$

where \( Z_E \) is the elasticity factor, \( F_t \) is tangential load, and \( K \)-factors account for dynamic conditions. Optimizing these parameters through testing directly enhances automotive gear longevity.

Durability Testing: High-Speed Challenges

Durability tests simulate real-world loads on gears, bearings, and synchronizers. Electrically closed-loop testers dominate modern setups due to superior accuracy. For electric vehicle (EV) reducers exceeding 15,000 RPM, new technical hurdles emerge:

- Vibration Control: High-speed shaft dynamics require precision balancing. The critical shaft speed \( n_{cr} \) must exceed test conditions:

$$ n_{cr} = \frac{30}{\pi} \sqrt{\frac{k}{m}} $$

where \( k \) = stiffness and \( m \) = mass. Advanced FEA ensures operational speeds stay below \( n_{cr} \). - Thermal Management: High-RPM efficiency losses demand active cooling.

- Reliability: 24/7 operation necessitates fail-safe controls (e.g., SIL-3 safety systems).

Performance Testing: Precision Diagnostics

Contact Pattern Analysis: Loaded gear mesh inspection reveals misalignment invisible in unloaded tests. Modern testers achieve ±0.05% torque accuracy and stabilize at ≥1 RPM for clear pattern capture. This prevents NVH issues and tooth breakage in automotive gear systems.

Lubrication Validation: Tilt-test rigs simulate vehicle angles and oil temperatures to verify bearing oil flow. Insufficient lubrication causes 70% of premature bearing failures – making this test indispensable before durability runs.

NVH Testing: Transmission Error (TE) is the primary noise excitation source:

$$ TE = \theta_{\text{output}} – \frac{\theta_{\text{input}}}{i} $$

where \( i \) = gear ratio. Electrically quiet dynamometers in hemi-anechoic chambers measure TE and noise radiation. Domestic 20,000 RPM NVH testers are now emerging to replace imports.

End-of-Line Testing: AI-Driven Quality Gates

Traditional unloaded “go/no-go” tests miss latent defects. Next-generation production testers integrate:

| Feature | Benefit | Defect Detection Rate |

|---|---|---|

| Robotic shift actuation | Eliminates human error in gear engagement | +40% shift faults |

| Loaded operation (10–100% torque) | Reveals bearing rumble, seal leaks | +35% load-related defects |

| AI-based vibration analytics | Flags abnormal signatures in 3–5 seconds | +25% early-stage failures |

Data from 50,000+ tests trains ML algorithms to predict automotive gear quality deviations unseen by threshold alarms.

Operational Monitoring: The Next Frontier

Embedded sensors in fielded transmissions enable real-time health monitoring. Key parameters include:

- Vibration FFT spectra for bearing spalling detection

- Oil debris counts for wear progression

- Temperature gradients for cooling efficiency

Current systems remain cost-prohibitive for mass-market vehicles, but digital-twin integration will drive adoption. The gear remaining useful life (RUL) prediction model exemplifies this:

$$ \text{RUL} = \int_{t_0}^{t_f} \frac{1}{\omega(t) \cdot \exp\left(\beta_0 + \beta_1 S(t)\right)} dt $$

where \( S(t) \) = stress history and \( \beta \) = material constants.

Future Trajectories: Intelligence and Integration

Three vectors will redefine automotive gear testing:

- High-Precision Systems: 0.001° encoder resolution and 20 kHz NVH sampling for EV micro-geometry validation.

- Unified Platforms: Modular testers combining durability, NVH, and TE capabilities with shared data lakes.

- AI Orchestration: Reinforcement learning for adaptive test profiles and root-cause diagnostics.

These advancements will close the gap with global leaders while addressing core weaknesses in high-speed bearings and multi-physics simulation.