In my investigation of high-speed transmission systems for aerospace applications, I focused on the dynamic transmission error (DTE) as a critical parameter for evaluating gear performance. This study compares straight bevel gears and zero degree spiral bevel gears in a two-stage cylindrical-bevel gear system, commonly used in engines. The zero bevel gear, despite theoretical advantages, exhibited unexpected dynamic issues in practical scenarios, prompting me to conduct detailed experimental analyses. I constructed a high-speed test platform to measure DTE under various operating conditions, employing spectral analysis to dissect the frequency components. My findings reveal that while the zero bevel gear offers superior transmission accuracy in low-frequency ranges, its high-frequency dynamic performance is inferior to that of straight bevel gears, leading to increased vibration and potential system failures. This contradiction with existing theories underscores the importance of real-world testing for such critical components.

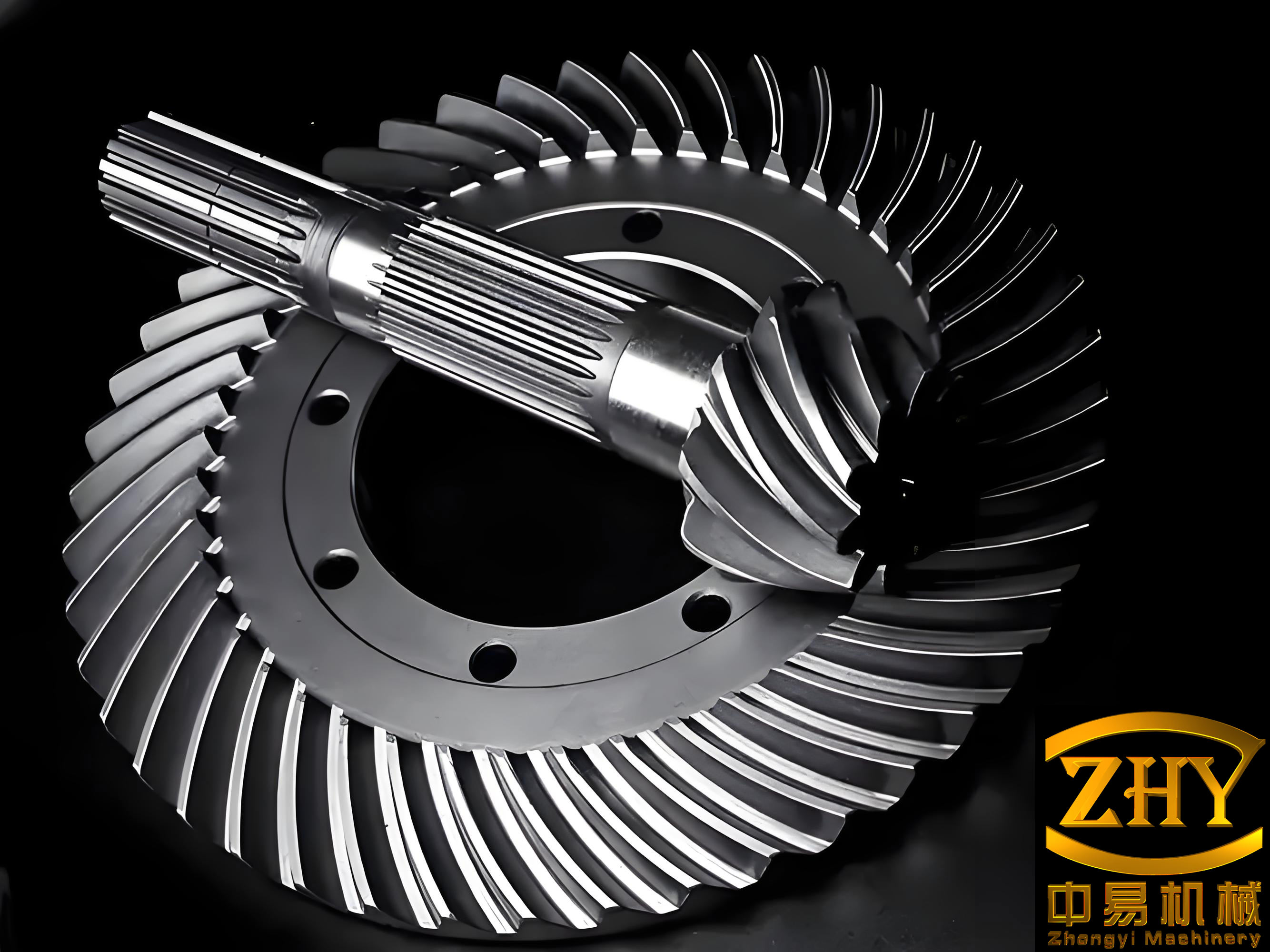

Gear transmissions are fundamental in mechanical systems due to their efficiency, compactness, and reliability. In aerospace engines, the performance of bevel gears, including the zero bevel gear, directly impacts overall system dynamics. Dynamic transmission error, defined as the deviation between the theoretical and actual angular positions of meshing gears, serves as a key indicator of vibrational excitation and noise. Traditional studies often emphasize the benefits of spiral bevel gears, such as smoother operation and higher load capacity, but my experience with a specific engine model showed that zero degree spiral bevel gears could induce severe vibrations. This led me to explore the underlying causes through empirical data, focusing on how DTE varies with gear type and operating speed.

To model DTE, I consider the gear system as a multi-body dynamic entity. The transmission error for a gear pair can be expressed as the difference in angular displacement between the driving and driven gears, accounting for elastic deformations and manufacturing imperfections. For a pair of meshing gears, the dynamic transmission error \(\Delta \theta\) is given by:

$$\Delta \theta(t) = \theta_1(t) – \theta_2(t) \cdot r,$$

where \(\theta_1(t)\) and \(\theta_2(t)\) are the instantaneous angular positions of the driving and driven gears, respectively, and \(r\) is the gear ratio. In frequency domain analysis, the DTE signal \(\Delta \theta(t)\) is transformed using Fourier analysis to identify dominant frequencies. The power spectral density (PSD) \(S(f)\) is computed as:

$$S(f) = \left| \int_{-\infty}^{\infty} \Delta \theta(t) e^{-i2\pi ft} dt \right|^2,$$

where \(f\) is the frequency. This allows me to isolate components related to shaft frequencies, mesh frequencies, and their harmonics. For the zero bevel gear, the mesh frequency \(f_m\) is calculated as \(f_m = N \cdot f_s\), where \(N\) is the number of teeth and \(f_s\) is the shaft rotational frequency. My analysis emphasizes comparing these spectral components between gear types to explain the observed dynamic behaviors.

The test system I designed addresses the challenges of high-speed DTE measurement, such as sensor limitations and data synchronization. I utilized high-precision angular encoders and magnetic gratings to capture real-time angular displacements. The virtual instrument platform, built on graphical programming, enabled continuous data acquisition at sampling rates sufficient to resolve high-frequency dynamics. Key parameters of the gear systems are summarized in the tables below to provide context for the analysis.

| Parameter | Pinion Value | Gear Value |

|---|---|---|

| Number of Teeth | 19 | 32 |

| Module (mm) | 2.25 | 2.25 |

| Pressure Angle (°) | 20 | 20 |

| Pitch Cone Angle | 30°41’59” | 59°18’1″ |

| Face Cone Angle | 34°34’24” | 61°34’40” |

| Root Cone Angle | 27°48’28” | 54°48’50” |

| Cone Distance (mm) | 51.17 | 51.17 |

| Face Width (mm) | 12 | 12 |

| Parameter | Pinion Value | Gear Value |

|---|---|---|

| Number of Teeth | 19 | 32 |

| Module (mm) | 2.25 | 2.25 |

| Pressure Angle (°) | 20 | 20 |

| Shaft Angle (°) | 90 | 90 |

| Spiral Angle (°) | 0 | 0 |

| Pitch Cone Angle | 30°42′ | 59°18′ |

| Face Cone Angle | 37°14′ | 64°1′ |

| Root Cone Angle | 25°59′ | 52°46′ |

| Addendum (mm) | 3.57 | 1.93 |

| Cone Distance (mm) | 51.17 | 51.17 |

| Face Width (mm) | 12 | 12 |

| Spiral Direction | Left | Right |

The shaft system geometry, crucial for understanding dynamic interactions, includes parameters like lengths and diameters that influence vibrational modes. For instance, the intermediate shaft’s length and bearing positions affect how excitations propagate through the system. In my tests, I varied the speed from 8,600 rpm to 17,032 rpm to cover typical operational ranges. The DTE data were filtered to separate low-frequency and high-frequency components, as the former relates to cumulative errors and the latter to dynamic mesh excitations.

For the straight bevel gear tests at 8,600 rpm, I observed that the DTE was dominated by low-frequency components corresponding to shaft frequencies and their harmonics. The intermediate shaft frequency \(f_{s2}\) and output shaft frequency \(f_{s3}\) were particularly prominent, with amplitudes decreasing under load. For example, the output shaft’s frequency component had a peak of 20.32 μrad unloaded, reducing to 12.91 μrad under load. This suggests that load conditions dampen some low-frequency vibrations. The high-frequency DTE, centered around the mesh frequency, showed modulation effects due to shaft interactions. Specifically, the mesh frequency of the bevel gears \(f_{m\_bevel}\) and the cylindrical gears \(f_{m\_cyl}\) interacted, with sidebands spaced at the intermediate shaft frequency. The equation for the modulated signal can be approximated as:

$$\Delta \theta_{hf}(t) = A_m \cos(2\pi f_m t) + \sum_k A_k \cos(2\pi (f_m \pm k f_s) t),$$

where \(A_m\) is the amplitude at mesh frequency, \(A_k\) are sideband amplitudes, and \(f_s\) is the shaft frequency. In the straight bevel gear case, the cylindrical gear’s double mesh frequency had the highest amplitude, modulated by the output shaft frequency.

In contrast, the zero bevel gear exhibited lower overall DTE in low-frequency ranges, indicating better transmission accuracy. However, the high-frequency components were significantly larger. At 8,600 rpm, the amplitudes at the cylindrical gear’s double mesh frequency and the zero bevel gear’s mesh frequency increased by 413% and 132%, respectively, compared to straight bevel gears. This is critical because high-frequency DTE directly correlates with dynamic loads and noise. The root mean square (RMS) value of high-frequency DTE for the zero bevel gear was higher, calculated as:

$$\text{RMS} = \sqrt{\frac{1}{T} \int_0^T (\Delta \theta_{hf}(t))^2 dt},$$

where \(T\) is the measurement period. This increase explains the excessive vibrations observed in the engine system when using zero bevel gears. The spectral analysis showed fewer modulation sidebands, implying that the zero bevel gear’s dynamics are less influenced by shaft frequencies but more by inherent mesh excitations.

To quantify the dynamic performance, I computed the transmission error variance \(\sigma^2\) as a function of speed and load. For a given gear pair, \(\sigma^2\) is proportional to the integral of the PSD over frequency. My results showed that for zero bevel gears, \(\sigma^2\) increased markedly in high-frequency bands, leading to poorer dynamic stability. The table below summarizes key DTE parameters at 8,600 rpm for both gear types under loaded conditions.

| Parameter | Straight Bevel Gear | Zero Bevel Gear |

|---|---|---|

| Low-Frequency Peak Amplitude (μrad) | 12.91 | 5.23 |

| High-Frequency RMS (μrad) | 0.15 | 0.62 |

| Mesh Frequency Amplitude (μrad) | 0.23 | 0.53 |

| Cylindrical Gear Double Mesh Amplitude (μrad) | 0.11 | 0.58 |

| Dominant Modulation | Output Shaft Frequency | Minimal |

The superiority of straight bevel gears in high-frequency dynamics can be attributed to their simpler tooth geometry, which reduces excitation at mesh frequencies. For zero bevel gears, the spiral tooth design, even with zero degrees, introduces complex contact patterns that amplify high-frequency vibrations. I derived a simplified model for mesh stiffness \(k_m(t)\) to explain this:

$$k_m(t) = k_0 + \sum_{n=1}^{\infty} k_n \cos(2\pi n f_m t + \phi_n),$$

where \(k_0\) is the average stiffness, and \(k_n\) are harmonics coefficients. For zero bevel gears, the variations in \(k_n\) are larger due to tooth curvature, leading to higher dynamic forces. This aligns with my spectral data, where the zero bevel gear showed pronounced peaks at harmonic frequencies of the mesh.

In extended tests across the speed range, I found that the dynamic transmission error for zero bevel gears consistently exhibited higher high-frequency content. For instance, at 12,000 rpm, the high-frequency RMS for zero bevel gears was 0.75 μrad compared to 0.18 μrad for straight bevel gears. This trend held under various loads, indicating that the issue is inherent to the gear design rather than operational conditions. The phase analysis of DTE signals further revealed that the zero bevel gear had larger phase shifts at high frequencies, contributing to torsional vibrations in the intermediate shaft. This explains the observed damage to cylindrical gears in the system, as the increased dynamics lead to fatigue loads.

My discussion emphasizes that while zero bevel gears offer advantages in static transmission accuracy, their dynamic drawbacks make them less suitable for high-speed applications where vibration control is critical. The engineering implication is that gear selection must balance accuracy and dynamic performance. For future designs, optimizing the tooth profile of zero bevel gears to reduce high-frequency excitations could be beneficial. Additionally, incorporating damping mechanisms in the shaft system might mitigate these issues.

In conclusion, my comprehensive analysis demonstrates that straight bevel gears outperform zero bevel gears in dynamic scenarios due to lower high-frequency transmission error. This study highlights the importance of empirical DTE measurements in validating gear performance, especially for critical aerospace systems. The insights gained can guide gear design and selection processes to enhance reliability and efficiency.