In the heavy machinery industry, the demand for larger gear rings in applications such as grinding mills, cement kilns, and power generation equipment has driven the development of gear hobbing processes for massive components. As a manufacturer specializing in large gear rings, we have extensively used imported high-speed CNC gear hobbing machines to produce cast steel gear rings with diameters exceeding 7 meters and weights over 40 tons. However, during gear hobbing operations, we frequently encountered critical issues with the rotary table and its support system, leading to machine downtime, reduced productivity, and compromised product quality. This article details our first-hand experience in analyzing these failures and implementing a comprehensive design improvement to enhance the stability and precision of gear hobbing machines.

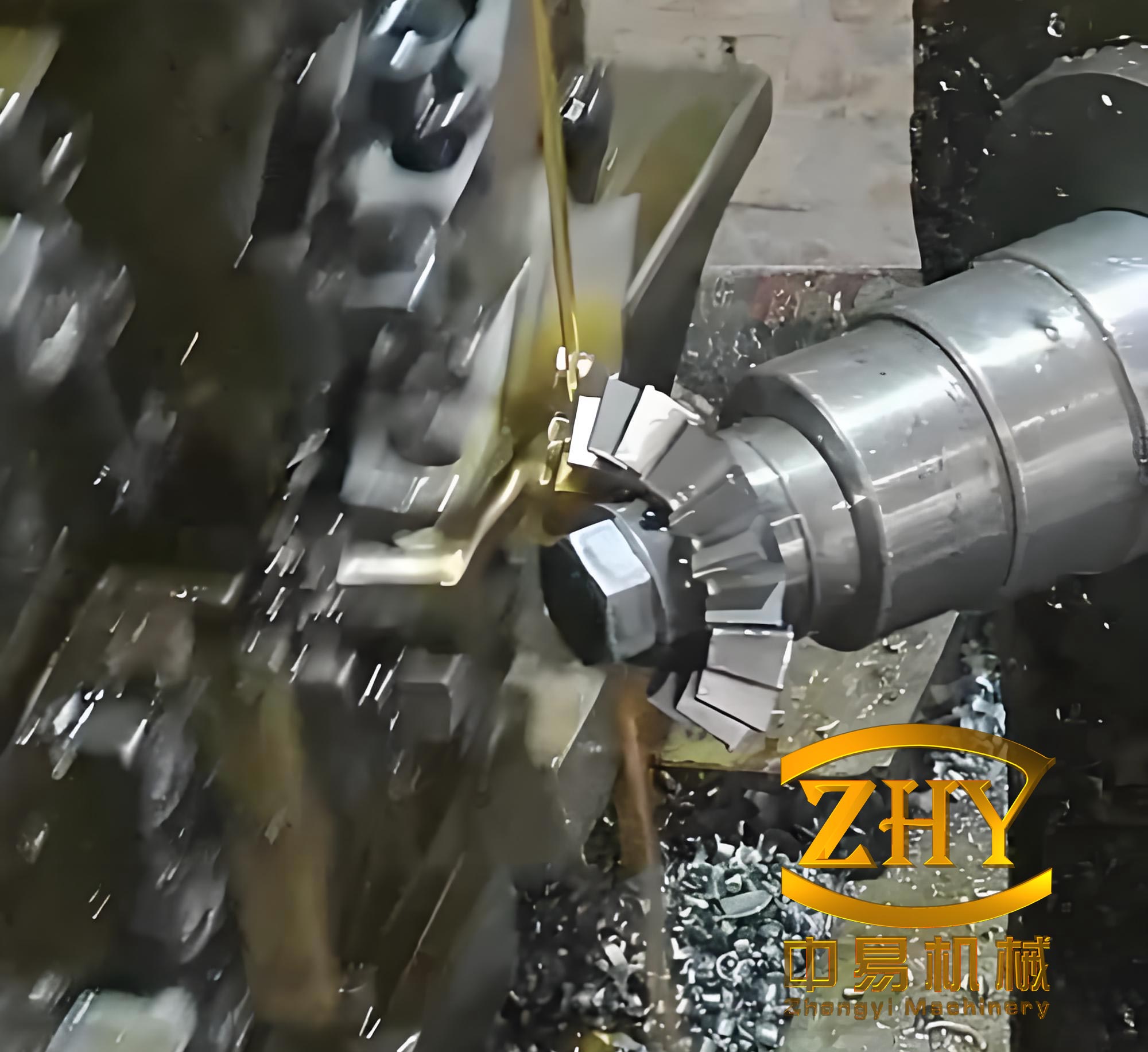

The gear hobbing process involves rotating a workpiece on a rotary table while a hobbing cutter engages it to form gear teeth. For large-diameter gear rings, the workpiece extends beyond the main table, necessitating an auxiliary rotary table supported by multiple components. In our setup, the rotary table导轨 (guide rails) rested on eight auxiliary support points, each equipped with bearings. Under high-speed gear hobbing conditions, with significant cutting depths and feed rates, the support system endured substantial impact forces during tool entry and exit. This resulted in repeated bearing failures and导轨 wear, as illustrated by the frequent cracking of bearing outer rings and severe scoring of the导轨 surfaces. Such issues not only halted production for repairs but also caused deviations in gear tooth profiles due to instantaneous table imbalances.

To address these challenges, we conducted a thorough failure analysis. The original support system utilized FAG 21319-E1-TVPB spherical roller bearings, which are designed to handle radial loads and moderate axial loads but proved inadequate for the high dynamic loads in gear hobbing applications. The total mass on the table, including the workpiece, table, and fixture, exceeded 100 tons, imposing extreme stresses. For instance, the radial load on each bearing was calculated using the formula for static load distribution: $$ F_r = \frac{W}{n} $$ where \( F_r \) is the radial load per bearing, \( W \) is the total weight, and \( n \) is the number of supports. With \( W = 102 \, \text{t} \) (approximately 1000 kN) and \( n = 8 \), each bearing faced a nominal load of 125 kN. However, additional forces from gear hobbing impacts amplified this, leading to overloading. The bearings’ inability to withstand torsional and axial moments during table rotation further contributed to their failure. Moreover, the导轨, made of cast steel with a hardness of 350–400 HBW, lacked sufficient wear resistance and became damaged when cracked bearings scraped against them.

Our改进方案 focused on three key areas: enhancing bearing capacity, redesigning the support assembly, and improving导轨 durability. We replaced the original bearings with NNTR90×220×100.2ZL heavy-duty support roller bearings, which feature a thick-walled outer ring and full complement of cylindrical rollers. This design allows for direct rolling on the导轨 and can handle heavier radial loads, impact forces, and combined moments. The bearing’s increased contact width (from 45 mm to 100 mm) and higher static load rating significantly boosted performance. The table below compares the specifications of the original and new bearings:

| Parameter | Original Bearing (FAG 21319-E1-TVPB) | New Bearing (NNTR90×220×100.2ZL) |

|---|---|---|

| Outer Diameter (mm) | 190 | 220 |

| Width (mm) | 45 | 100 |

| Static Load Rating (kN) | 430 | 750 |

| Dynamic Load Capacity (kN) | 380 | 600 |

The bearing’s static load capacity improved by approximately 74.4%, calculated as: $$ \text{Improvement} = \frac{750 – 430}{430} \times 100\% = 74.4\% $$ This enhancement directly addressed the overloading issue in gear hobbing machines. Additionally, we redesigned the support assembly to accommodate the new bearings and optimize functionality. The new assembly includes an adjustment ring for precise gap control between the bearing and导轨, a 45° lubrication port for easy grease application, and shielding plates to prevent chip ingress. The bearing housing was enclosed to protect against contaminants, ensuring longevity in harsh gear hobbing environments.

Installation and alignment were critical to the success of the改进方案. We developed a specialized tool to measure and equalize the height of all eight bearings, ensuring uniform contact with the导轨. The tool, mounted on the main table, used a dial indicator to scan each bearing’s top surface during rotation. By adjusting the rings, we maintained a gap within 0.02 mm and reduced planar runout to below 0.03 mm. This minimized impact forces and distributed loads evenly, crucial for stable gear hobbing operations. The alignment process can be modeled using the equation for runout error: $$ \delta = \sqrt{\sum_{i=1}^{n} (h_i – \bar{h})^2} $$ where \( \delta \) is the runout, \( h_i \) is the height of each bearing, and \( \bar{h} \) is the average height. By keeping \( \delta < 0.03 \, \text{mm} \), we ensured smooth table rotation.

For the导轨, we adopted a modular design with replaceable segments made from 45 steel, bolted to the rotary table. The segments were joined with steep-angle seams to reduce冲击 when bearings crossed joints. To enhance hardness, we applied super-frequency quenching, a surface hardening technique that achieves deep case depths with minimal distortion. The quenching process involves induction heating followed by rapid cooling, resulting in a surface hardness exceeding 60 HRC. After stress relief and machining, the final hardness stabilized above 58 HRC, comparable to the bearing surfaces. The hardness transformation can be described by the empirical formula for quenching depth: $$ d = k \sqrt{t} $$ where \( d \) is the depth of hardness, \( k \) is a material constant, and \( t \) is the quenching time. For 45 steel, \( k \approx 0.5 \, \text{mm/s}^{1/2} \), allowing us to control distortion within 0.3 mm through press straightening. This approach extended导轨 life and facilitated easy replacements, reducing downtime in gear hobbing processes.

The practical application of these improvements over three years demonstrated remarkable results. No bearing cracks occurred, and the导轨 surfaces retained machining marks with negligible wear. Table stability improved, maintaining runout within 0.03 mm during high-speed gear hobbing. This enhanced precision allowed for consistent gear tooth profiles and eliminated quality issues like tool marks. Productivity increased due to reduced interruptions, and the modular导轨 design lowered maintenance costs. The following table summarizes the performance metrics before and after the改进方案:

| Metric | Before Improvement | After Improvement |

|---|---|---|

| Bearing Failure Frequency | High (multiple times per project) | None |

| 导轨 Wear | Severe, requiring frequent repairs | Minimal, no visible damage |

| Table Runout (mm) | > 0.1 | < 0.03 |

| Production Downtime | Significant due to repairs | Reduced by over 80% |

| Gear Quality Issues | Common (e.g., tooth scoring) | Eliminated |

In conclusion, our design improvements for the rotary table and support components in high-speed CNC gear hobbing machines have resolved chronic issues of bearing failure and导轨 wear. By upgrading to heavy-duty roller bearings, optimizing the support assembly, and implementing hardened, replaceable导轨, we achieved greater machine stability and precision. These enhancements are vital for gear hobbing large, high-precision components, as they ensure reliable performance under heavy loads and high speeds. The use of advanced materials and precise alignment techniques has extended equipment life, boosted efficiency, and minimized economic losses from downtime. This approach sets a benchmark for future innovations in gear hobbing machine design, particularly as industry demands push toward larger and more complex gear systems.

Furthermore, the principles applied here can be adapted to other heavy-duty machining processes. For instance, the bearing selection criteria and导轨 hardening methods may benefit similar applications in milling or turning large workpieces. As gear hobbing technology evolves, continuous monitoring and refinement of these components will be essential. We plan to explore digital twin simulations for predictive maintenance, further optimizing the gear hobbing process. Through such efforts, we aim to contribute to the advancement of manufacturing capabilities globally, ensuring that gear hobbing machines remain at the forefront of precision engineering.