In modern manufacturing, high-speed gear hobbing has emerged as a critical process for producing gears with high efficiency and minimal environmental impact. Unlike traditional cutting methods that rely on cutting fluids, high-speed gear hobbing operates without such fluids, enabling faster cutting rates and reducing pollution. This paper focuses on optimizing the process parameters of high-speed gear hobbing to achieve lower energy consumption and improved gear quality. The optimization approach combines an improved Multi-Objective Gray Wolf Optimization (MOGWO) algorithm with the Technique for Order Preference by Similarity to Ideal Solution (TOPSIS) for multi-attribute decision-making. By iteratively refining parameters such as axial feed rate, spindle speed, hob diameter, and number of hob starts, the method aims to balance conflicting objectives like energy efficiency and gear accuracy. Experimental results demonstrate that the proposed algorithm reduces machining energy consumption by 6.3% and decreases gear error by 24.6%, highlighting its effectiveness in enhancing the performance of gear hobbing processes.

The gear hobbing process involves the continuous rotation of a hob tool to generate gear teeth through a series of coordinated movements. In high-speed gear hobbing, the absence of cutting fluids leads to heat accumulation in the cutting zone, which can cause thermal deformation and affect gear quality. Therefore, optimizing parameters is essential to mitigate these issues. Previous studies have explored various aspects, such as tool life, cost, heat generation, and dimensional accuracy, but often lack a comprehensive multi-objective framework. This work addresses this gap by integrating MOGWO for parameter optimization and TOPSIS for decision-making, providing a robust solution for industrial applications.

The optimization model considers four key variables: axial feed rate (denoted as $v_a$), spindle speed ($n_0$), hob diameter ($d_0$), and number of hob starts ($z_0$). Among these, $v_a$, $n_0$, and $d_0$ are continuous variables, while $z_0$ is discrete. The objectives are to minimize machining energy consumption ($E$) and gear quality error ($Q$), which are often conflicting. For instance, higher feed rates may reduce energy but increase errors. The MOGWO algorithm is employed to handle this multi-objective problem by simulating the social hierarchy and hunting behavior of gray wolves, where solutions are represented as positions in a search space. The algorithm iteratively updates these positions to approach the Pareto-optimal front, and TOPSIS is then used to rank the solutions based on their proximity to the ideal point.

The mathematical formulation of the optimization problem is as follows. Let $X = (v_a, n_0, d_0, z_0)$ represent a candidate solution. The objectives are defined as:

$$ \text{Minimize } F(X) = [E(X), Q(X)] $$

where $E(X)$ is the machining energy consumption and $Q(X)$ is the gear quality error. Constraints include bounds on the variables:

$$ 68 \, \text{mm/min} \leq v_a \leq 92 \, \text{mm/min} $$

$$ 650 \, \text{r/min} \leq n_0 \leq 780 \, \text{r/min} $$

$$ d_0 \in \{78, 79, \dots, 89\} \, \text{mm} $$

$$ z_0 \in \{2, 3\} $$

The MOGWO algorithm models the wolf pack with four hierarchy levels: alpha ($\alpha$), beta ($\beta$), delta ($\delta$), and omega ($\omega$). The $\alpha$ wolf represents the best solution, guiding the search process. The position update equations are:

$$ D = C \odot (X_p(t) – X(t)) $$

$$ X(t+1) = X_p(t) – A \odot D $$

where $A$ and $C$ are coefficient vectors computed as:

$$ A = 2a r_1 – a E $$

$$ C = 2 r_2 $$

Here, $a$ is a parameter that decreases linearly from 2 to 0 over iterations, $r_1$ and $r_2$ are random vectors in [0, 1], $E$ is a vector of ones, and $\odot$ denotes the Hadamard product. The distance $D$ measures the proximity to the prey (optimal solution). The algorithm ensures a balance between exploration and exploitation by adjusting $A$; when $|A| > 1$, the wolves explore widely, and when $|A| < 1$, they exploit local regions.

To handle discrete variables like $z_0$, the algorithm incorporates a rounding mechanism during position updates. The improved MOGWO also modifies the update coefficient $a$ to enhance convergence speed and avoid local optima. The fitness of each wolf is evaluated based on the objective functions $E(X)$ and $Q(X)$, and non-dominated solutions are stored in an archive. After the MOGWO process, the TOPSIS method is applied to the archive solutions. TOPSIS calculates the Euclidean distance of each solution to the ideal and negative-ideal solutions, assigning a score for ranking. The decision matrix is normalized, and weights are assigned to each objective (e.g., 0.5 for both energy and quality in this study).

The workflow of the algorithm is summarized as follows. First, initialize the wolf population with random positions within bounds. Then, for each iteration, compute the objectives for all wolves. Update the $\alpha$, $\beta$, and $\delta$ wolves based on non-domination and crowding distance. Adjust the positions using the hunting equations, and apply constraints to ensure feasibility. After maximum iterations, output the Pareto-optimal set. Finally, use TOPSIS to rank the solutions and select the best one based on the application requirements.

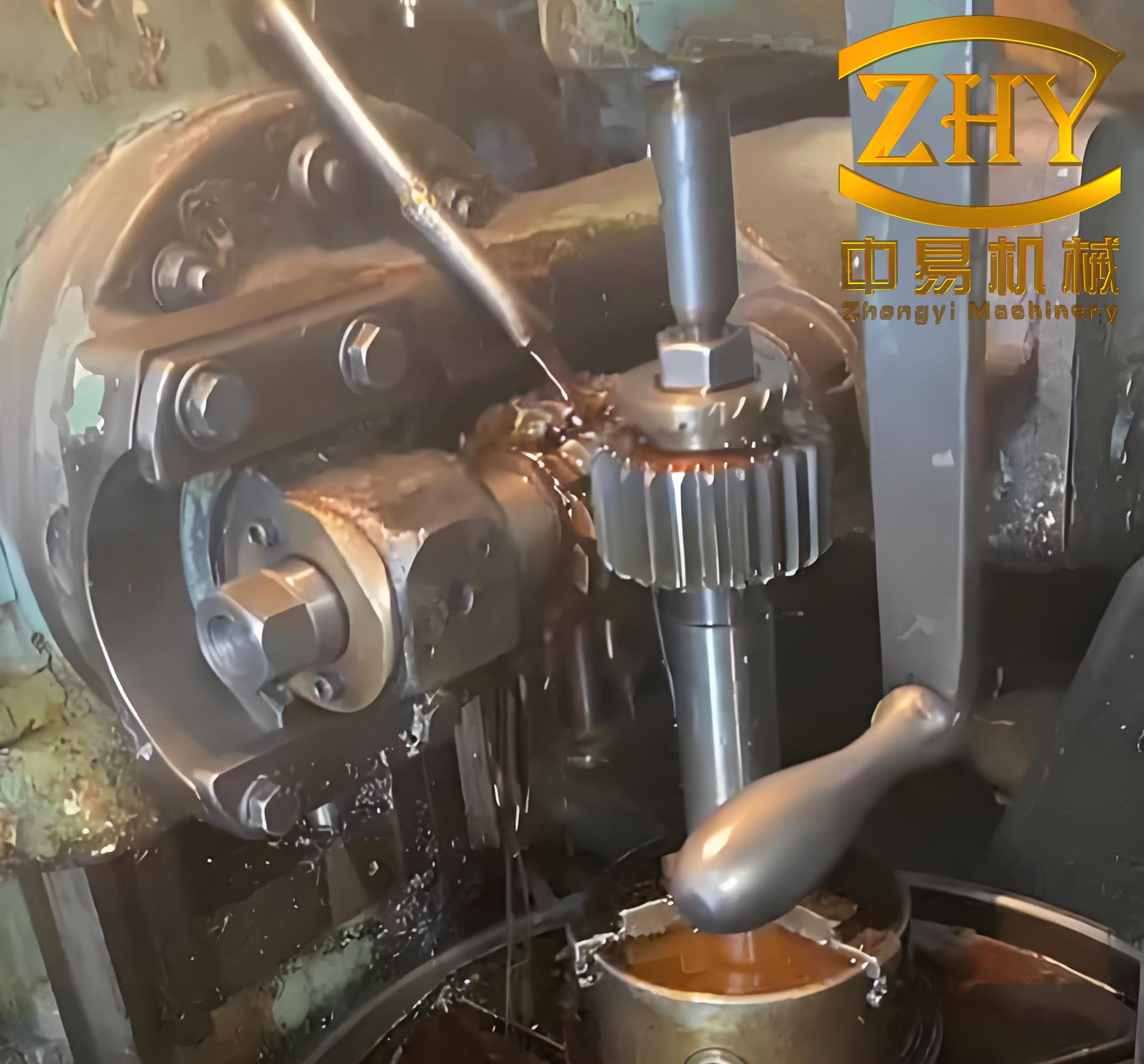

Experiments were conducted using a YKS3112CNC7 high-speed gear hobbing machine to validate the proposed method. This gear hobbing machine is capable of dry machining and is equipped with a 3 kW motor, offering a precision grade of 8. The test gear had a module of 6.5 mm, 48 teeth, a pitch diameter of 312 mm, and a face width of 32 mm. Key parameters included a helix angle of 60° and a feed rate of 0.12 mm/rev. The gear hobbing process was monitored for energy consumption using a power meter, and gear quality was assessed through error measurements on a coordinate measuring machine.

The algorithm was implemented in MATLAB, with a population size of 20 wolves and a maximum of 200 iterations. The control parameters were set as follows: grid number of 10, inflation rate of 0.1, and the number of objectives as 2. The variable ranges were as specified earlier. After optimization, 16 non-dominated solutions were obtained, representing trade-offs between energy consumption and gear quality. The results are presented in the table below, which includes the parameter values and corresponding objective values for each solution.

| Solution | $v_a$ (mm/min) | $n_0$ (r/min) | $d_0$ (mm) | $z_0$ | $Q$ (mm) | $E$ (MJ) |

|---|---|---|---|---|---|---|

| P1 | 91.00 | 782.01 | 89 | 2 | 0.035 | 0.16 |

| P2 | 91.00 | 772.39 | 88 | 3 | 0.085 | 0.81 |

| P3 | 91.00 | 781.98 | 89 | 3 | 0.432 | 0.63 |

| P4 | 69.00 | 649.92 | 78 | 2 | 0.143 | 0.72 |

| P5 | 68.33 | 752.28 | 78 | 2 | 0.048 | 1.35 |

| P6 | 80.96 | 780.87 | 89 | 3 | 0.055 | 0.74 |

| P7 | 80.03 | 780.00 | 89 | 3 | 0.353 | 6.85 |

| P8 | 69.00 | 780.00 | 89 | 3 | 0.015 | 10.96 |

| P9 | 69.00 | 780.00 | 89 | 3 | 0.014 | 7.68 |

| P10 | 69.00 | 754.23 | 89 | 3 | 0.016 | 6.85 |

| P11 | 74.38 | 780.00 | 89 | 3 | 0.017 | 13.32 |

| P12 | 68.40 | 739.35 | 82 | 3 | 0.016 | 2.85 |

| P13 | 76.75 | 782.45 | 89 | 3 | 0.032 | 4.63 |

| P14 | 69.00 | 754.77 | 89 | 3 | 0.030 | 3.12 |

| P15 | 74.66 | 780.00 | 89 | 3 | 0.025 | 7.85 |

| P16 | 69.00 | 762.32 | 89 | 3 | 0.022 | 10.06 |

Analysis of the results reveals that improving gear quality often leads to a reduction in energy consumption, as seen in solutions like P8 and P9. For example, when the hob diameter is larger (e.g., 89 mm), the cutting time decreases, enhancing productivity and tool rigidity. This is because a larger hob diameter allows for a larger inner hole, improving the stiffness of the gear hobbing machine tool and extending its service life. Additionally, solutions with a higher number of hob starts (e.g., $z_0 = 3$) tend to reduce energy consumption by shortening the machining time, but they may also increase gear errors if not properly balanced.

The relationship between process parameters and objectives is further illustrated through mathematical expressions. For instance, the energy consumption $E$ can be modeled as a function of axial feed rate and spindle speed:

$$ E = k_1 \cdot v_a + k_2 \cdot n_0 + k_3 \cdot d_0 + k_4 \cdot z_0 $$

where $k_1$, $k_2$, $k_3$, and $k_4$ are coefficients determined empirically. Similarly, gear quality error $Q$ might follow:

$$ Q = c_1 \cdot \frac{1}{v_a} + c_2 \cdot n_0 + c_3 \cdot d_0 + c_4 \cdot z_0 $$

These models highlight the complex interactions between parameters. For example, higher spindle speeds increase energy consumption but may reduce errors due to smoother cuts. The TOPSIS method helps in resolving these trade-offs by calculating a composite score. The decision matrix $R$ is normalized to $R’$, and the weighted normalized matrix $V$ is computed as:

$$ v_{ij} = w_j \cdot r’_{ij} $$

where $w_j$ is the weight for objective $j$. The ideal solution $A^+$ and negative-ideal solution $A^-$ are defined as:

$$ A^+ = (\min v_{i1}, \min v_{i2}) \quad \text{for minimization objectives} $$

$$ A^- = (\max v_{i1}, \max v_{i2}) $$

The separation measures are calculated using Euclidean distance:

$$ S_i^+ = \sqrt{\sum_{j=1}^{2} (v_{ij} – A_j^+)^2} $$

$$ S_i^- = \sqrt{\sum_{j=1}^{2} (v_{ij} – A_j^-)^2} $$

Finally, the relative closeness $C_i$ is given by:

$$ C_i = \frac{S_i^-}{S_i^+ + S_i^-} $$

Solutions with higher $C_i$ are preferred. The table below shows the TOPSIS scores for the 16 solutions, with P8, P3, and P6 ranking highest.

| Rank | Score | Solution |

|---|---|---|

| 1 | 0.1345 | P8 |

| 2 | 0.1503 | P3 |

| 3 | 0.1436 | P6 |

| 4 | 0.1194 | P9 |

| 5 | 0.0938 | P7 |

| 6 | 0.0385 | P10 |

| 7 | 0.0467 | P4 |

| 8 | 0.0664 | P14 |

| 9 | 0.0553 | P2 |

| 10 | 0.0356 | P5 |

| 11 | 0.0224 | P11 |

| 12 | 0.0245 | P1 |

| 13 | 0.0351 | P16 |

| 14 | 0.0124 | P15 |

| 15 | 0.0064 | P13 |

| 16 | 0.0067 | P12 |

For validation, the proposed method was compared to a standard gray wolf optimization algorithm combined with TOPSIS. The results, summarized in the table below, show that the improved MOGWO approach achieves better performance, with a 6.3% reduction in energy consumption and a 24.6% decrease in gear error. This demonstrates the efficacy of the enhancements in the optimization algorithm for gear hobbing applications.

| Method | $v_a$ (mm/min) | $n_0$ (r/min) | $d_0$ (mm) | $z_0$ | $Q$ (mm) | $E$ (MJ) |

|---|---|---|---|---|---|---|

| Proposed | 69.00 | 782.00 | 89 | 3 | 0.035 | 149.63 |

| Traditional | 73.56 | 735.29 | 89 | 3 | 0.042 | 152.62 |

In conclusion, this study presents a comprehensive framework for optimizing high-speed gear hobbing process parameters using an improved MOGWO and TOPSIS approach. The key findings are threefold. First, enhancing gear quality generally leads to lower energy consumption, as observed in the Pareto-optimal solutions. Second, larger hob diameters and higher numbers of hob starts contribute to reduced machining time and improved tool life, which are critical for the efficiency of gear hobbing machines. Third, the integration of TOPSIS enables effective decision-making by considering real-world trade-offs between energy and quality. The proposed algorithm significantly outperforms traditional methods, making it a valuable tool for manufacturers seeking to optimize their gear hobbing processes. Future work could explore dynamic parameter adjustments and real-time monitoring to further enhance performance.

The gear hobbing process is integral to the production of precision gears, and advancements in optimization techniques like those discussed here can lead to substantial improvements in sustainability and productivity. By repeatedly applying the terms ‘gear hobbing’ and ‘gear hobbing machine’ throughout this text, the importance of these concepts in manufacturing is emphasized. The use of mathematical models and algorithmic frameworks ensures that the optimization is both theoretically sound and practically applicable, providing a roadmap for future research in smart manufacturing environments.