In modern gear manufacturing, the use of indexable insert hobs (ICI hobs) has become increasingly prevalent, especially in high-volume production of large-module gears. As a mechanical engineer specializing in gear processing, I have observed that ICI hobs offer significant advantages in terms of cutting efficiency, economic viability, and environmental friendliness. These tools employ carbide inserts with high hardness, wear resistance, and thermal stability, enabling cutting speeds exceeding 100 m/min. This represents a substantial improvement over conventional high-speed steel or powder metallurgy hobs. Moreover, the replaceable nature of the inserts reduces auxiliary time and tool inventory, making ICI hobs ideal for batch production. However, despite these benefits, maintaining consistent gear hobbing accuracy remains a challenge. In this article, I will analyze the factors affecting gear hobbing precision with ICI hobs, including insert overlap errors, installation inaccuracies, and wear, and explore the optimization of processing parameters using Design of Experiments (DOE) to enhance tooth profile accuracy.

The gear hobbing process involves the use of a gear hobbing machine to generate gear teeth through a continuous indexing motion. With ICI hobs, the tooth profile is formed by the spatial overlap of multiple inserts, which can introduce errors if not properly controlled. From my experience, the gear hobbing machine’s stability and the hob’s design play crucial roles in achieving desired tolerances. For instance, in mass production, even minor deviations can lead to significant quality issues, such as excessive noise or reduced load capacity in the final gear. Therefore, understanding and mitigating these errors is essential for optimizing the gear hobbing process.

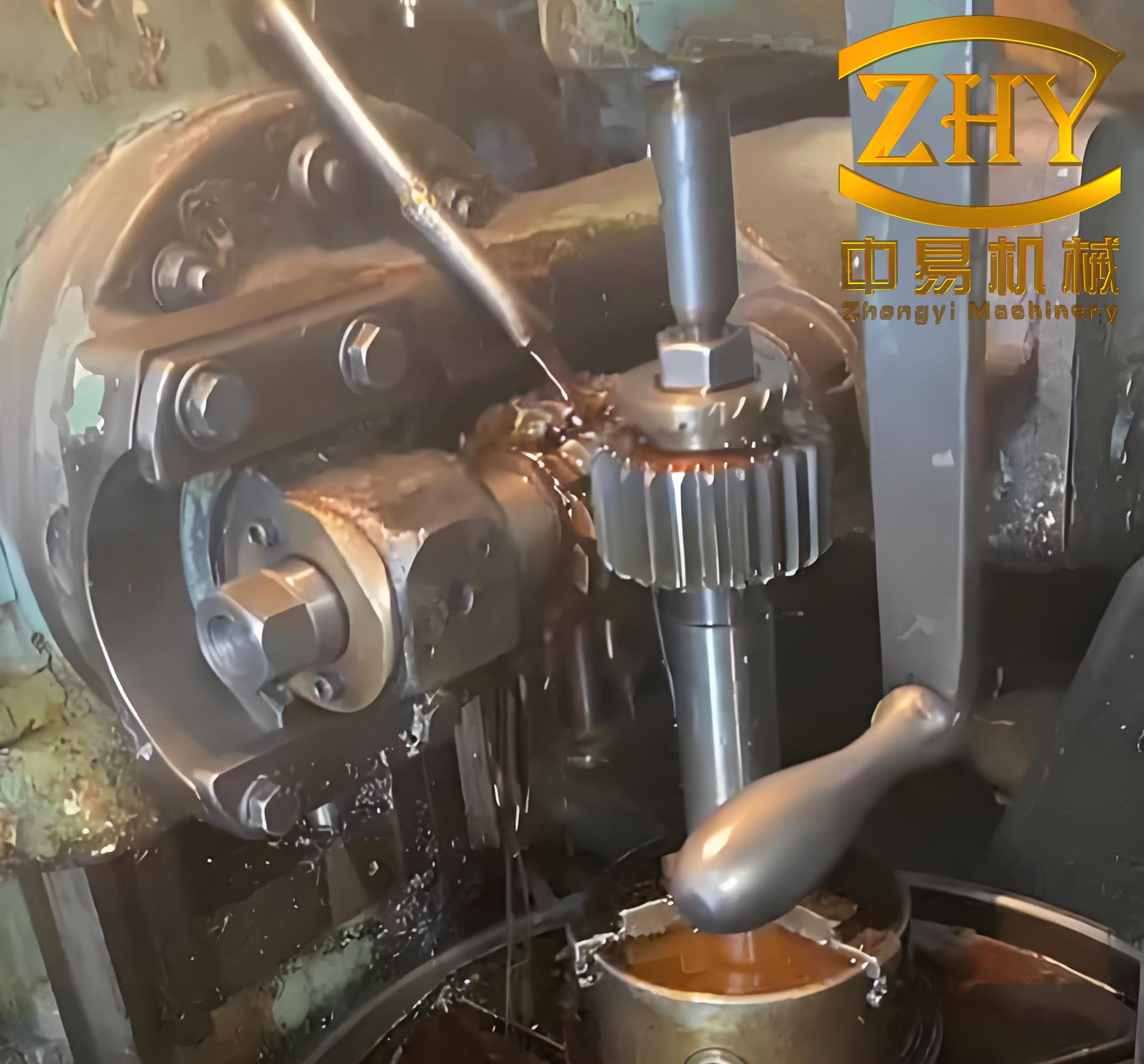

One critical aspect is the insert overlap error. In ICI hobs, the tooth profile is constructed by joining top and side inserts, as illustrated in the design. If the overlap between these inserts is not precise due to manufacturing tolerances or design flaws, the machined gear surface may exhibit abnormal steps or ridges. This can directly impact the profile slope deviation (fHα), profile form deviation (ffα), and total profile deviation (Fα), potentially causing the gear to fall outside the required accuracy class, such as ISO 9. For example, in a case I encountered, an overlap error led to irregular fluctuations in the tooth profile measurement report, rendering the hob unusable until corrections were made. To address this, rigorous inspection and adjustment of the insert seating slots during the tool design phase are necessary. The relationship between overlap error and profile deviation can be expressed using a basic geometric formula: $$ \Delta P = \sqrt{(\Delta x)^2 + (\Delta y)^2} $$ where ΔP represents the resultant profile error, and Δx and Δy denote the errors in the horizontal and vertical directions of insert positioning. By minimizing these errors through precise manufacturing, the overall gear hobbing accuracy can be improved.

Another factor I have investigated is the insert installation error. ICI hob inserts are secured into the tool body using screws and locating slots, and any deviation in installation can compromise accuracy. The screws engage with tapered holes in the inserts, which helps in achieving a tight fit and proper alignment. However, if the tightening torque is too high, it can cause insert fracture, as I have seen in several instances. Conversely, insufficient torque may lead to insert loosening during high-speed gear hobbing, resulting in tool damage and poor tooth profile. Based on my observations, adhering to the manufacturer’s recommended torque values is critical. Additionally, during insert replacement, cleaning the locating slots to remove debris is essential to prevent inaccuracies. The effect of installation error on profile deviation can be modeled as: $$ E_i = k \cdot \Delta T $$ where E_i is the installation-induced error, k is a constant dependent on the hob design, and ΔT is the deviation from the optimal torque. This highlights the importance of controlled assembly in the gear hobbing process.

Insert wear is also a major concern in gear hobbing with ICI hobs. Over time, the carbide inserts undergo coating wear and thermal degradation, leading to edge decarburization and softening. As the wear progresses, the cutting performance declines, causing poor surface finish and, eventually, chipping or breakage of the insert. In my work, I have monitored insert conditions regularly; for instance, when the flank wear exceeds a certain limit, it results in pronounced ridges along the tooth flank, making the gear unsuitable for further use. The wear rate can be described by Taylor’s tool life equation adapted for hobbing: $$ V \cdot T^n = C $$ where V is the cutting speed, T is the tool life, n is an exponent, and C is a constant. For ICI hobs, this relationship emphasizes the need for timely insert replacement to maintain gear hobbing accuracy. In practice, I recommend inspecting inserts after each batch and replacing them when signs of excessive wear, such as whitening or irregular edges, appear.

To quantitatively analyze the impact of processing parameters on tooth profile accuracy, I conducted a study using Design of Experiments (DOE). This approach allows for efficient exploration of multiple factors with minimal trials, which is crucial in optimizing the gear hobbing process. The study focused on a planetary gear with a module of 14 mm, processed on a standard gear hobbing machine. The key parameters investigated were axial feed speed, hob lead angle compensation, and number of cutting strokes. These factors were chosen because they directly influence the cutting forces and thermal conditions during gear hobbing. The table below summarizes the basic parameters of the gear and hob used in the study.

| Parameter | Value |

|---|---|

| Module (mm) | 14 |

| Number of Teeth | 38 |

| Pressure Angle (°) | 22.5 |

| Helix Angle (°) | 7.16 |

| Face Width (mm) | 358 |

| Parameter | Value |

|---|---|

| Module (mm) | 14 |

| Pressure Angle (°) | 22.5 |

| Helix Angle (°) | 3.651 |

| Number of Starts | 1 |

| Effective Number of Teeth | 12 |

| Outside Diameter (mm) | 260 |

The DOE was structured as a 3-factor, 2-level design with four center points to assess curvature and interactions. The factors and their levels are detailed in the table below. Note that the lead angle compensation refers to an artificial adjustment of the hob’s helix angle input on the gear hobbing machine to alter the effective cutting angle, which can balance the cutting conditions on both flanks.

| Factor | Low Level | High Level | Center Point |

|---|---|---|---|

| Axial Feed Speed (mm/rev) | 1.0 | 1.9 | 1.45 |

| Lead Angle Compensation (°) | 0 | 1 | 0.5 |

| Number of Cutting Strokes | 1 | 3 | 2 |

After conducting the experiments, I measured the tooth profile deviations—fHα, ffα, and Fα—for each trial and analyzed the data using statistical software. The Pareto charts from the analysis revealed that axial feed speed and lead angle compensation had significant effects on fHα and ffα, while interactions among all factors influenced Fα. For instance, the relationship between axial feed speed and profile deviation can be expressed using the feed mark depth formula: $$ \delta_x = \frac{(f_a / \cos \beta_0)^2 \cdot \sin \alpha_n}{4 \cdot d_{a0}} $$ where δ_x is the feed mark depth, f_a is the axial feed speed, β_0 is the helix angle, α_n is the pressure angle, and d_{a0} is the hob’s tip diameter. This equation shows that higher feed speeds increase δ_x, leading to greater profile errors. In the response optimizer, I set the objective to minimize the deviations while constraining the number of strokes to one to maintain efficiency. The optimal solution was found at low axial feed speed (1.0 mm/rev) and high lead angle compensation (1°), which theoretically ensures the gear meets ISO 9 accuracy.

To validate these findings, I performed 12 production runs with the optimized parameters. The results demonstrated a notable improvement: the proportion of gears exceeding ISO 9 accuracy for tooth profile dropped from 53% to approximately 25%. The process capability analysis indicated that the predicted non-conformance rates for fHα, ffα, and Fα were below 9%, 17.8%, and 2.5%, respectively. This confirms that parameter optimization via DOE can effectively enhance gear hobbing accuracy with ICI hobs. Moreover, the gear hobbing machine’s performance was stable throughout, underscoring the importance of integrating tool design with process control.

In conclusion, as a mechanical engineer focused on gear manufacturing, I have found that indexable insert hobs are invaluable for high-efficiency gear hobbing, but their accuracy depends on careful management of design and operational factors. Insert overlap errors must be minimized through precise tool manufacturing, while installation errors require strict torque control. Additionally, monitoring insert wear and replacing inserts proactively can prevent catastrophic failures. Through DOE-based optimization of processing parameters, such as reducing axial feed speed and adjusting lead angle compensation, significant improvements in tooth profile accuracy can be achieved without sacrificing productivity. This holistic approach—combining robust tool design with data-driven process optimization—ensures that gear hobbing with ICI hobs meets the demanding standards of modern industries, such as wind energy and automotive sectors. Future work could explore the integration of real-time monitoring systems in gear hobbing machines to further enhance accuracy and tool life.

From a broader perspective, the gear hobbing process with ICI hobs exemplifies the synergy between advanced tooling and machining strategies. As gear hobbing machines evolve to support higher speeds and automation, the role of optimized parameters becomes even more critical. In my experience, continuous improvement in gear hobbing not only boosts quality but also reduces costs and environmental impact, aligning with sustainable manufacturing goals. Therefore, I recommend that engineers regularly review and update their gear hobbing protocols based on empirical data and technological advancements to stay competitive in the field.