In modern precision engineering, harmonic gear reducers are widely used in aerospace, robotics, and general machinery due to their compact size, high transmission ratio, strong load capacity, and high positioning accuracy. The flexspline, a critical component of harmonic gears, is typically a large modified thin-walled gear with a significant modification coefficient, often around 3. The gear hobbing process for such large modified gears presents unique challenges, as standard hobbing tools can introduce substantial machining errors, compromising the near-zero backlash meshing required for precision transmission. This article investigates the formation mechanism of large modified flexsplines through gear hobbing simulation, analyzes the theoretical machining errors on the tooth surface, and explores the causes, providing guidance for selecting gear hobbing parameters to improve accuracy. We establish parametric equations for the hob cutting edges, develop a mathematical model for hobbing formation based on the relative motion between the hob and workpiece, and create an evaluation model for theoretical machining errors. Simulation calculations of tooth surface errors are performed, and gear hobbing experiments validate the correctness of the simulations. Our findings indicate that increasing the hob length effectively reduces errors caused by insufficient cutting at the tooth tip, and we calculate the minimum hob length for complete cutting. Additionally, reducing the axial feed of the hob significantly decreases tooth surface errors, and we derive the relationship curve between the maximum tooth alignment error and the axial feed.

The gear hobbing process involves complex interactions between the hob and the workpiece, necessitating a detailed mathematical model to simulate the cutting mechanism. For large modified gears, such as the flexspline in harmonic drives, the gear hobbing machine must be precisely controlled to avoid errors. We begin by defining the parametric equations for the hob cutting edges. The axial tooth profile of an Archimedes hob is represented in the hob coordinate system O1-X1Y1, where the X1-axis coincides with the hob axis, and the Y1-axis bisects the axial tooth profile. The tooth profile parameters include the tooth tip height ha1 = 1.35mn and tooth root height hf1 = mn, where mn is the normal module of the hob. The axial tooth profile is expressed as a function of the parameter s:

$$ P_1(s) = [s, Y_1(s), 0, 1]^T $$

where Y1(s) is the Y1-coordinate in the hob coordinate system, given by:

$$ Y_1(s) = \begin{cases}

r_h – h_{f1} & \text{for } x_2 < s \leq P_a / 2 \\

r_h + (P_a / 4 – s) \cot \alpha_x & \text{for } x_3 < s \leq x_2 \\

D_h / 2 – r_c + \sqrt{r_c^2 – (s – x_4)^2} & \text{for } x_4 < s \leq x_3 \\

D_h / 2 & \text{for } -x_4 < s \leq x_4

\end{cases} $$

Here, rh is the hob pitch radius, Pa is the axial pitch, αx is the axial pressure angle, Dh is the hob outer diameter, and rc is the tip radius. The coordinates x2, x3, and x4 are defined as:

$$ x_2 = P_a / 4 + h_{f1} \tan \alpha_x $$

$$ x_3 = P_a / 4 – [h_{a1} – r_c(1 – \sin \alpha_x)] \tan \alpha_x $$

$$ x_4 = x_3 – r_c \cos \alpha_x $$

The series of cutting edges on the hob are generated by rotating the axial tooth profile around the X1-axis. The k-th cutting edge is expressed as:

$$ L_1^k(s) = M_1^k P_1(s) $$

where the transformation matrix M1k is:

$$ M_1^k = \begin{bmatrix}

1 & 0 & 0 & k P_a \gamma_s / (Z_L \gamma_s) \\

0 & \cos(2\pi k / Z_L) & -\sin(2\pi k / Z_L) & 0 \\

0 & \sin(2\pi k / Z_L) & \cos(2\pi k / Z_L) & 0 \\

0 & 0 & 0 & 1

\end{bmatrix} $$

ZL is the number of hob gullets, and γs is the helix angle (positive for right-hand hobs, negative for left-hand hobs). This parametric model allows us to simulate the gear hobbing process accurately.

Next, we develop the mathematical model for hobbing formation of the modified gear. The relative position and motion between the hob and workpiece during gear hobbing are illustrated in Figure 2. The coordinate systems include the hob coordinate system O1-X1Y1Z1, the hob installation system O2-X2Y2Z2, the hob reference system O3-X3Y3Z3, the workpiece reference system O4-X4Y4Z4, the workpiece system O5-X5Y5Z5, and the machine fixed system O6-X6Y6Z6. The radial installation distance a is calculated as:

$$ a = r_g + r_h + x m_n $$

where rg is the gear pitch radius, x is the modification coefficient, and mn is the normal module. The axial feed μ as a function of the hob rotation angle φ is:

$$ \mu(\phi) = \pm \frac{N f \phi}{2\pi z} $$

where the sign depends on the milling direction (positive for climb milling, negative for conventional milling), N is the number of hob starts, z is the number of gear teeth, and f is the axial feed per revolution of the workpiece. The workpiece rotation angle ψ is related to the hob rotation angle by:

$$ \psi(\phi) = \pm \frac{N \phi}{z} $$

The spatial trajectory of the hob cutting edges in the workpiece coordinate system O5-X5Y5Z5 envelopes the gear tooth surface. The homogeneous coordinates of the trajectory surface for the k-th cutting edge are:

$$ G_g^k(s, \phi) = M_5^4 M_4^2 M_2^1 L_1^k(s) $$

where the transformation matrices are:

$$ M_2^1 = \begin{bmatrix}

1 & 0 & 0 & 0 \\

0 & \cos \phi & \sin \phi & 0 \\

0 & -\sin \phi & \cos \phi & 0 \\

0 & 0 & 0 & 1

\end{bmatrix} $$

$$ M_4^2 = \begin{bmatrix}

\cos \gamma_i & 0 & -\sin \gamma_i & 0 \\

0 & 1 & 0 & a \\

\sin \gamma_i & 0 & \cos \gamma_i & \mu(\phi) \\

0 & 0 & 0 & 1

\end{bmatrix} $$

$$ M_5^4 = \begin{bmatrix}

\cos \psi & -\sin \psi & 0 & 0 \\

\sin \psi & \cos \psi & 0 & 0 \\

0 & 0 & 1 & 0 \\

0 & 0 & 0 & 1

\end{bmatrix} $$

γi is the hob installation angle. This model enables the simulation of the gear hobbing process for large modified gears.

The theoretical tooth surface of the gear is parameterized based on the involute profile. For a spur gear, the tooth slot surface is formed by translating the involute curve along the gear axis. The homogeneous coordinates of the i-th tooth slot surface are:

$$ F_i(\theta, w) = \begin{bmatrix}

\pm [r_b \sin(\theta – \Omega – i \cdot \Delta) – r_b \theta \cos(\theta – \Omega – i \cdot \Delta)] \\

r_b \cos(\theta – \Omega – i \cdot \Delta) + r_b \theta \sin(\theta – \Omega – i \cdot \Delta) \\

w \\

1

\end{bmatrix} $$

where the sign depends on the side of the involute (positive for the right side, negative for the left), rb is the base circle radius, θ is the involute unfolding angle, w is the displacement along the gear axis, Ω is the rotation angle of the standard involute, given by Ω = π/(2z) – 2x tan αn / z – tan αn + αn, αn is the normal pressure angle, and Δ = 2π/z is the phase difference between adjacent slots. The surface normal vector at any point is obtained from the cross product of the partial derivatives:

$$ \mathbf{n}_i(\theta, w) = \frac{\partial F_i(\theta, w)}{\partial \theta} \times \frac{\partial F_i(\theta, w)}{\partial w} $$

This parameterized model is used to evaluate the theoretical tooth surface and compare it with the simulated hobbed surface.

To simulate the gear hobbing process, we use MATLAB to compute the theoretical tooth surface grid points and their normal vectors. The hob cutting edges are transformed into the gear coordinate system, and the intersections between the normal vectors and the cutting trajectories are calculated. The minimum distance from each grid point to the cutting trajectories is taken as the machining error at that point. A positive error indicates deviation in the direction of the normal vector, while negative indicates the opposite. The tooth surface error function δi(θ, w) is obtained by interpolating these error values. By fixing one parameter, we can derive the tooth profile error (varying θ) and tooth alignment error (varying w).

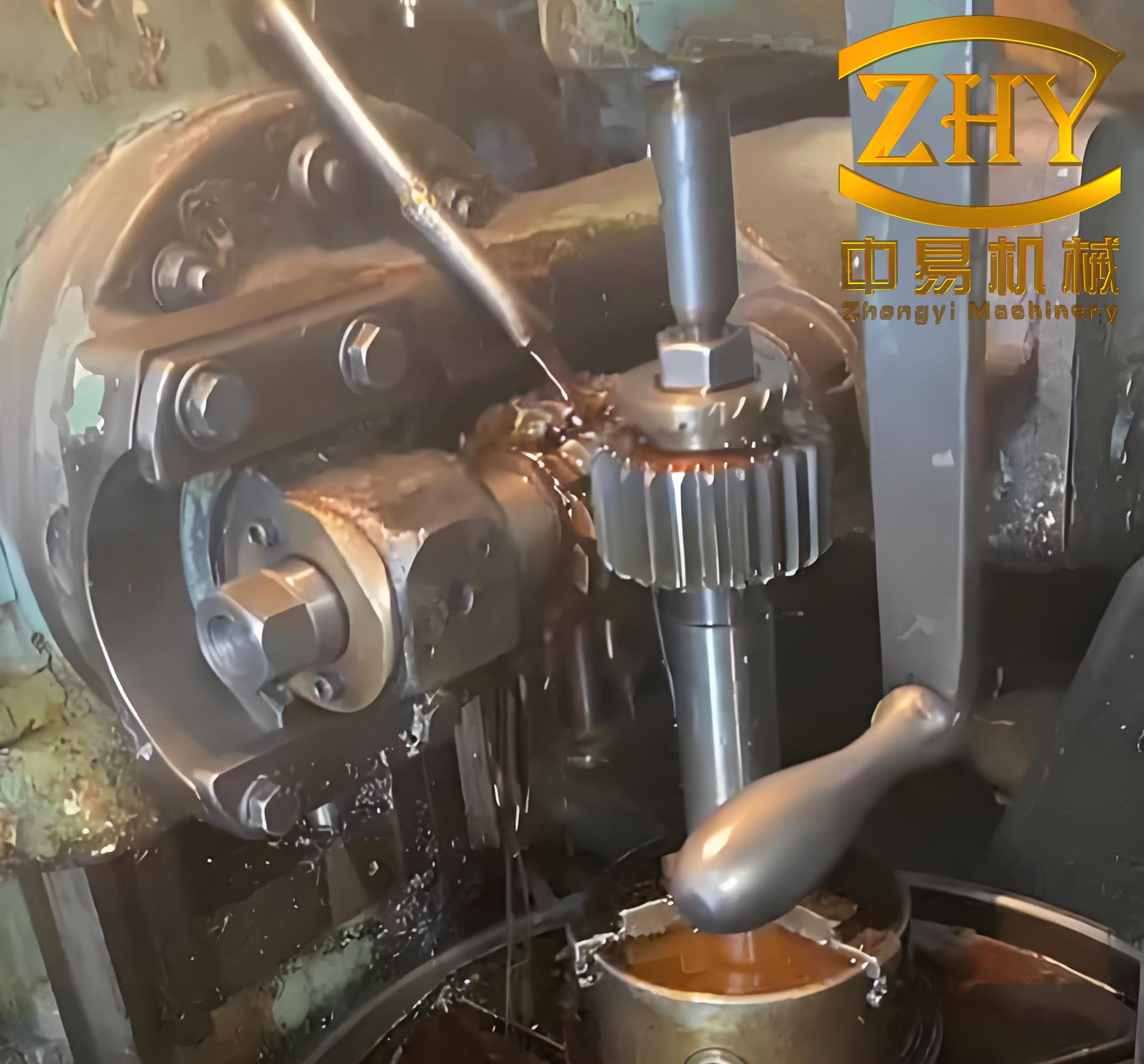

We conducted gear hobbing experiments to validate the simulation results. Two gears were processed: one with a modification coefficient of 0 and another with 3. The main parameters of the gears and hob are listed in Tables 1 and 2. The gear hobbing machine was operated at a hob speed of 450 rpm and an axial feed of 1.5 mm/rev. The tooth surface errors were measured using a coordinate measuring machine (CMM), which recorded the actual surface points relative to the theoretical grid points. The measured errors were compared with the simulation results for both tooth profile and tooth alignment errors.

| Module | Modification Coefficient | Pressure Angle (°) | Number of Teeth | Tip Diameter (mm) | Root Diameter (mm) |

|---|---|---|---|---|---|

| 2.5 | 0 | 20 | 90 | 230 | 218.75 |

| 2.5 | 3 | 20 | 90 | 245 | 233.75 |

| Module | Pressure Angle (°) | Number of Starts | Number of Gullets | Outer Diameter (mm) | Hand |

|---|---|---|---|---|---|

| 2.5 | 20 | 1 | 10 | 65 | Left |

The comparison between measured and simulated tooth profile errors for both gears showed close agreement, with similar error patterns. For the standard gear, the errors were relatively uniform, while for the large modified gear, errors increased near the tooth tip due to insufficient cutting. The tooth alignment errors also exhibited wavy patterns that matched between simulation and measurement, confirming the accuracy of our model.

We then focused on the error analysis for large modified flexsplines, using a typical harmonic gear flexspline with parameters listed in Table 3 and a standard hob with parameters in Table 4. The simulation used a hob with 73 effective cutting teeth and an axial feed of 1.5 mm/rev. The tooth surface topology error for the right flank of the 0th tooth slot is shown in Figure 7, revealing significant errors near the tooth tip and wavy patterns along the tooth width due to the axial feed.

| Module | Modification Coefficient | Pressure Angle (°) | Number of Teeth | Tip Diameter (mm) | Root Diameter (mm) |

|---|---|---|---|---|---|

| 0.5 | 3 | 20 | 200 | 104 | 101.65 |

| Module | Pressure Angle (°) | Number of Starts | Number of Gullets | Outer Diameter (mm) | Hand |

|---|---|---|---|---|---|

| 0.5 | 20 | 1 | 12 | 32 | Left |

The large errors near the tooth tip are attributed to insufficient cutting by the hob teeth. In standard gear hobbing, the central cutting teeth primarily form the tooth profile, but for large modified gears, the central teeth do not contribute effectively, and teeth farther from the center are required, leading to cutting insufficiency at the tip. We calculated the minimum hob length required to avoid this issue by determining the number of effective cutting teeth needed. For the flexspline in Table 3, the required hob teeth numbers at different diameters near the tip are shown in Table 5. At the tip diameter, teeth numbers 41 and -41 are needed for the left and right flanks, respectively, resulting in a minimum of 83 effective teeth.

| Diameter (mm) | 103.544 | 103.658 | 103.772 | 103.886 | 104 |

|---|---|---|---|---|---|

| 0 Left Flank | 37 | 38 | 39 | 40 | 41 |

| 0 Right Flank | -37 | -38 | -39 | -40 | -41 |

The relationship between the number of effective hob teeth and the modification coefficient is plotted in Figure 9. As the modification coefficient increases, the required hob length grows significantly to prevent cutting errors.

Tooth alignment errors are influenced by the axial feed of the hob. Since the feed is discontinuous, errors are minimized at feed positions and maximized between them. We simulated tooth alignment errors for axial feeds of 1.5, 1, and 0.5 mm/rev, as shown in Figure 10. The maximum error decreases substantially with reduced feed: from about 5.4 μm at 1.5 mm/rev to 0.6 μm at 0.5 mm/rev. The relationship between the maximum tooth alignment error and axial feed is derived and plotted in Figure 11, indicating a strong correlation where error reduction is achieved by lowering the feed.

We verified these findings through additional simulations. With an increased hob length of 83 effective teeth, the tooth profile errors near the tip are significantly reduced, as shown in Figures 12 and 13 for the right and left flanks, respectively. Further reducing the axial feed to 0.5 mm/rev minimizes the errors, with maximum tooth profile errors around 0.6 μm. This demonstrates that both hob length and axial feed are critical parameters in gear hobbing for large modified gears.

In conclusion, our study on the gear hobbing of large modified flexsplines reveals that standard hobs can cause significant errors due to insufficient cutting at the tooth tip, but these can be mitigated by increasing the hob length and reducing the axial feed. The mathematical models and simulation approach provide a reliable tool for optimizing gear hobbing processes. For precision applications like harmonic gears, careful selection of hob parameters and gear hobbing machine settings is essential to achieve high accuracy. Future work could explore the effects of other gear hobbing parameters, such as hob wear and dynamic cutting forces, on tooth surface quality.