As a key equipment in gear manufacturing, the advancement of CNC gear hobbing machines directly impacts the precision and efficiency of high-end manufacturing industries. With the rise of intelligent manufacturing, traditional gear hobbing machines face challenges such as insufficient mechanical transmission accuracy and poor process adaptability, necessitating breakthroughs through CNC upgrades and intelligent innovations. In this article, we explore the principles, applications, and future directions of CNC gear hobbing machines, emphasizing how these technologies drive progress in sectors like aerospace and automotive manufacturing.

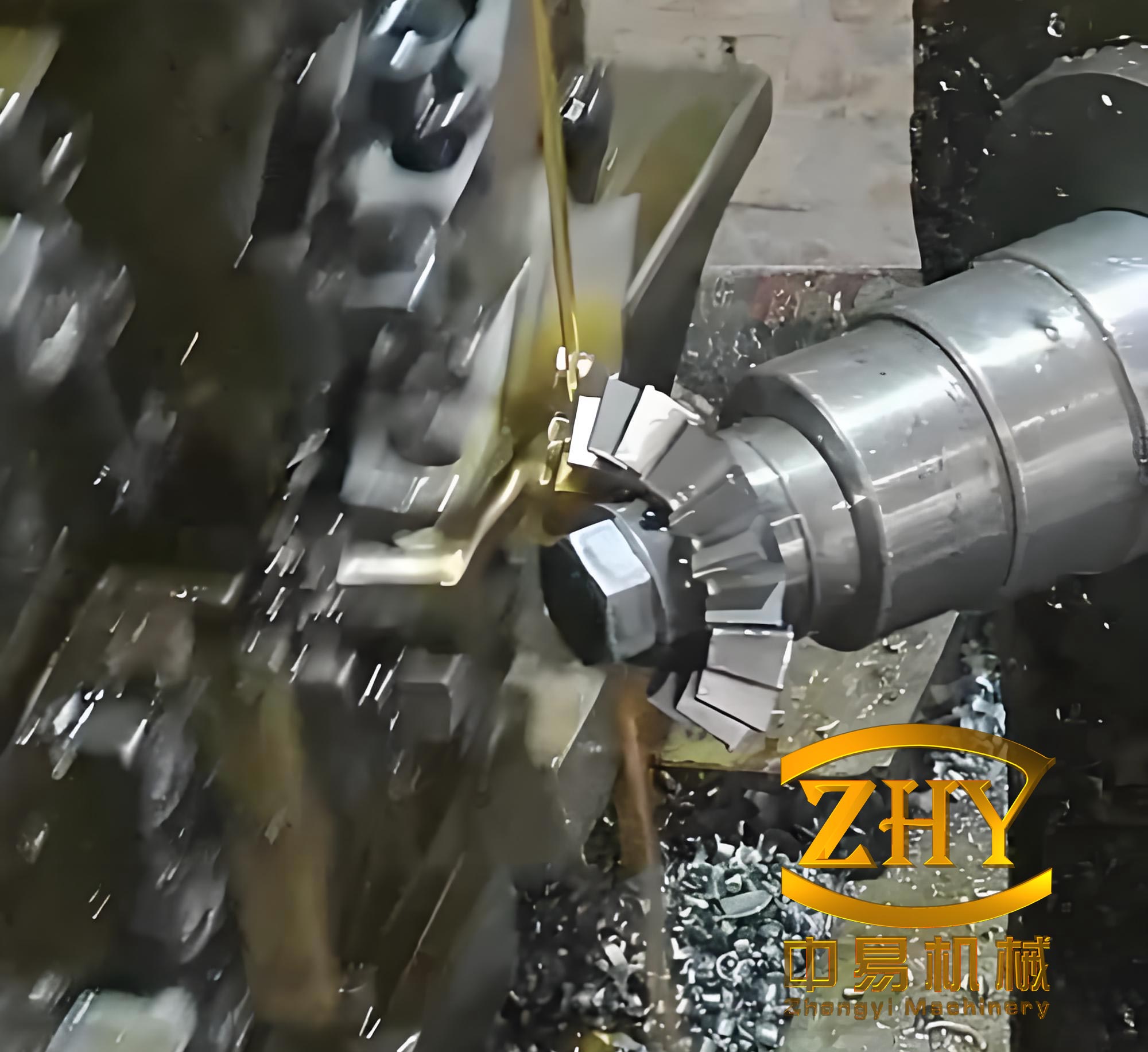

The gear hobbing process operates on the generating principle, where the relative motion between the hob and the gear blank envelops the hob’s cutting edge trajectory to form the gear tooth profile. The shape of the hob’s cutting edges determines the gear tooth profile, and the motion accuracy directly influences the gear machining precision. In traditional gear hobbing machines, this motion is achieved through complex mechanical transmission structures, which often introduce significant backlash and accuracy control issues. CNC gear hobbing machines integrate modern numerical control technology to precisely regulate parameters such as hob rotation, axial feed, and radial feed, thereby mitigating errors caused by mechanical transmission gaps. The use of CNC systems enables more complex motion trajectories, such as those required for non-circular gears or crown gears, and allows flexible adjustment of machining parameters to enhance productivity and product quality. Through the interpolation function of CNC systems, the hob’s motion can be accurately simulated, ensuring correct tooth formation. Additionally, CNC-upgraded gear hobbing machines feature data communication capabilities, facilitating data exchange with external devices and supporting automation and informatization in production processes. Real-time monitoring and fault diagnosis further improve operational safety and stability, reduce maintenance costs, and propel gear manufacturing into a new era of intelligence.

In CNC gear hobbing, the selection of process parameters critically affects machining efficiency, quality, and cost. Key parameters include cutting speed, feed rate, and depth of cut. Higher cutting speeds can reduce machining time but may accelerate tool wear and increase thermal deformation, compromising gear accuracy. Therefore, factors such as tool material, gear material, and workpiece hardness must be considered to determine an optimal cutting speed. For instance, when using high-speed steel tools for carbon steel gears, the cutting speed can be set within a specific range, whereas carbide tools allow for higher speeds when machining high-strength alloy steels. The feed rate must balance surface roughness requirements with productivity; it depends on tool sharpness and gear complexity. Simpler gears with lower precision demands permit higher feed rates, while high-precision complex gears require reduced rates. Proper coordination between axial and radial feeds ensures stable cutting conditions, preventing issues like tooth chipping or breakage. The depth of cut influences machining efficiency; excessive depths can lead to high cutting forces and machine vibration, affecting accuracy. Thus, roughing operations may use larger depths to quickly remove material, while finishing operations employ smaller depths to achieve desired precision and surface quality. The table below summarizes typical parameter ranges for different scenarios in gear hobbing.

| Parameter | Roughing Operation | Finishing Operation | Material Type |

|---|---|---|---|

| Cutting Speed (m/min) | 30-60 | 60-120 | Carbon Steel |

| Feed Rate (mm/rev) | 0.1-0.3 | 0.05-0.15 | Alloy Steel |

| Depth of Cut (mm) | 2-5 | 0.5-1.5 | Hardened Materials |

The quality control system for CNC gear hobbing is a comprehensive framework covering all stages of the machining process. Pre-machining controls involve strict inspections of raw materials to ensure gear blanks meet dimensional accuracy and surface quality standards, along with checks on tool sharpness and geometric tolerances. Regular maintenance and calibration of the CNC gear hobbing machine are essential to verify the accuracy of the CNC system and mechanical stability. During machining, real-time monitoring using sensors tracks parameters like cutting force and temperature; anomalies trigger immediate adjustments. Sampling and measurement with advanced instruments, such as coordinate measuring machines, assess tooth profile accuracy, tooth direction accuracy, and surface roughness. Post-machining controls include final product inspections and performance tests, such as contact strength and fatigue life assessments. A robust traceability system records processing and quality data for each batch, enabling quick root cause analysis and corrective actions. The overall quality can be modeled using equations that account for cumulative errors; for example, the total error $$E_{total}$$ in gear hobbing can be expressed as:

$$E_{total} = \sqrt{E_{mechanical}^2 + E_{thermal}^2 + E_{tool}^2}$$

where $$E_{mechanical}$$ represents mechanical transmission errors, $$E_{thermal}$$ thermal deformation errors, and $$E_{tool}$$ tool wear errors. By minimizing these components through systematic controls, the gear hobbing process achieves higher reliability.

CNC gear hobbing machines excel in manufacturing high-precision complex gears, which are vital in aerospace, automotive, and other advanced sectors. For special tooth profiles, such as helical or hypoid gears, CNC programming enables precise control of complex hob paths. Multi-axis synchronization allows multiple operations in a single setup, reducing clamping errors and enhancing accuracy. In producing high-precision involute gears, high-resolution position detection systems in CNC gear hobbing machines ensure exact hob rotation and axial feed control, coupled with high-performance tools to achieve micron-level tooth profile errors. For large high-precision gears, structural improvements in gear hobbing machines, including robust bed designs and high-stiffness transmission systems, counteract vibrations and maintain machining integrity. The integration of intelligent processing systems further augments capabilities by merging information technology with gear hobbing techniques. Sensors—such as temperature, vibration, and force sensors—gather real-time data on cutting conditions, enabling proactive adjustments. For example, temperature sensors detect overheating risks, allowing parameter modifications to sustain stable operations. Automation systems link CNC units with programmable logic controllers (PLCs) to manage tasks like automatic start-stop and tool changes. Industrial Ethernet facilitates communication with production management systems, enabling real-time monitoring and scheduling optimization. Artificial intelligence, particularly machine learning algorithms, analyzes historical and real-time data to predict tool wear and optimize parameters, thereby boosting efficiency and quality. This intelligent ecosystem positions CNC gear hobbing machines as competitive assets in modern manufacturing.

Innovations in CNC gear hobbing focus on multi-modal fusion intelligent control, which integrates visual, force, and thermal sensory data to enhance adaptability. Visual systems inspect gear surface quality in real-time, identifying defects like scratches or chipped teeth; force systems perceive cutting force variations to adjust parameters dynamically; and thermal systems monitor heat distribution to prevent localized overheating. After data acquisition, feature extraction and fusion employ AI algorithms, such as convolutional neural networks, for pattern recognition and decision-making. For instance, if a visual defect is detected, the system correlates it with force and thermal data to diagnose causes—like excessive depth of cut—and auto-corrects parameters while marking affected areas. This approach enables self-adaptive adjustments tailored to specific gear materials and requirements, significantly improving accuracy, efficiency, and versatility in complex tasks. The control logic can be represented by a decision function $$D$$ that combines multi-modal inputs:

$$D = f(V, F, T) = \alpha \cdot V + \beta \cdot F + \gamma \cdot T$$

where $$V$$, $$F$$, and $$T$$ denote visual, force, and thermal inputs, respectively, and $$\alpha$$, $$\beta$$, $$\gamma$$ are weighting coefficients optimized through machine learning. This fusion is a key trend in advancing intelligent gear hobbing machines.

Process technology innovations aim to elevate齿形精度, efficiency, and surface quality. Hybrid methods combining generating and forming principles allow for more complex and accurate tooth profiles. Digital twin technology creates virtual models of the gear hobbing process, simulating and optimizing parameters before physical machining. For efficiency gains, high-speed gear hobbing techniques are developed through improved hob designs—such as novel cutting edge geometries and materials—and enhanced transmission systems in gear hobbing machines to reduce losses and increase responsiveness. Continuous processing strategies, like automatic tool changers with interchangeable hob heads, minimize non-cutting time. Surface quality is boosted by integrating post-hobbing treatments, such as ion implantation, which hardens tooth surfaces for better wear and corrosion resistance. The relationship between cutting parameters and surface roughness $$R_a$$ can be approximated by:

$$R_a = k \cdot v^{-a} \cdot f^{b} \cdot d^{c}$$

where $$v$$ is cutting speed, $$f$$ is feed rate, $$d$$ is depth of cut, and $$k$$, $$a$$, $$b$$, $$c$$ are material-dependent constants. Optimizing these parameters through iterative testing or AI-driven models pushes gear hobbing toward higher performance standards.

Building a smart manufacturing ecosystem around CNC gear hobbing machines involves creating interconnected workshops where devices like machining centers and inspection equipment collaborate seamlessly. IoT technology enables real-time data transmission to central platforms, offering transparency in production processes—managers can monitor gear hobbing machine status and faults remotely via terminals. In supply chain integration, data sharing among raw material suppliers, tool providers, and gear blank manufacturers facilitates demand forecasting and inventory optimization, cutting costs. A full-lifecycle quality traceability system tracks products from raw materials to end-use, ensuring accountability. Collaboration with universities and research institutes fosters产学研 synergy, translating theoretical advances into practical applications. Talent development is crucial for cultivating professionals skilled in both gear hobbing technology and intelligent systems, supporting sustainable growth. The table below outlines key components of this ecosystem.

| Component | Description | Benefits |

|---|---|---|

| Interconnected Workshop | Integration of gear hobbing machines with other devices via IoT | Real-time monitoring and optimized scheduling |

| Smart Supply Chain | Data sharing among stakeholders for demand prediction | Reduced inventory costs and improved efficiency |

| Quality Traceability | End-to-end tracking from materials to final products | Quick problem identification and resolution |

| Research Collaboration | Partnerships with academic institutions for innovation | Accelerated technology adoption and refinement |

In conclusion, CNC gear hobbing machines provide a foundation for intelligent gear manufacturing, yet challenges remain in areas like multi-modal data fusion algorithms, where real-time performance and robustness require further validation. Process innovations such as high-speed gear hobbing and digital twins are still in experimental phases, facing hurdles in cost and stability for large-scale implementation. Future research should focus on dynamic optimization of machining parameters, strengthened industry-academia partnerships, and the development of open smart manufacturing platforms. Through continuous efforts, CNC gear hobbing machines are poised to play an expanded role in fields like aerospace and new energy vehicles, driving the transformation and upgrading of high-end equipment manufacturing. The potential for gear hobbing to integrate with emerging technologies promises even greater advancements in precision and automation.