In modern automotive manufacturing, the assembly of rack and pinion gear systems in electric power steering mechanisms presents significant challenges due to the need for high precision, repeatability, and efficiency. As a researcher focused on automation technologies, I have extensively studied the automatic assembly process for helical gears and racks to address issues such as high assembly forces, low yield rates, and potential component damage. The rack and pinion gear assembly is critical for ensuring accurate steering response and reducing noise in vehicles. This paper delves into the key aspects of the process, including rack tooth surface positioning, synchronous meshing strategies, mathematical modeling, guiding functions, and control parameters, providing a comprehensive reference for similar applications. Through systematic analysis and optimization, I aim to demonstrate how automated systems can enhance productivity and quality while minimizing costs in mass production environments.

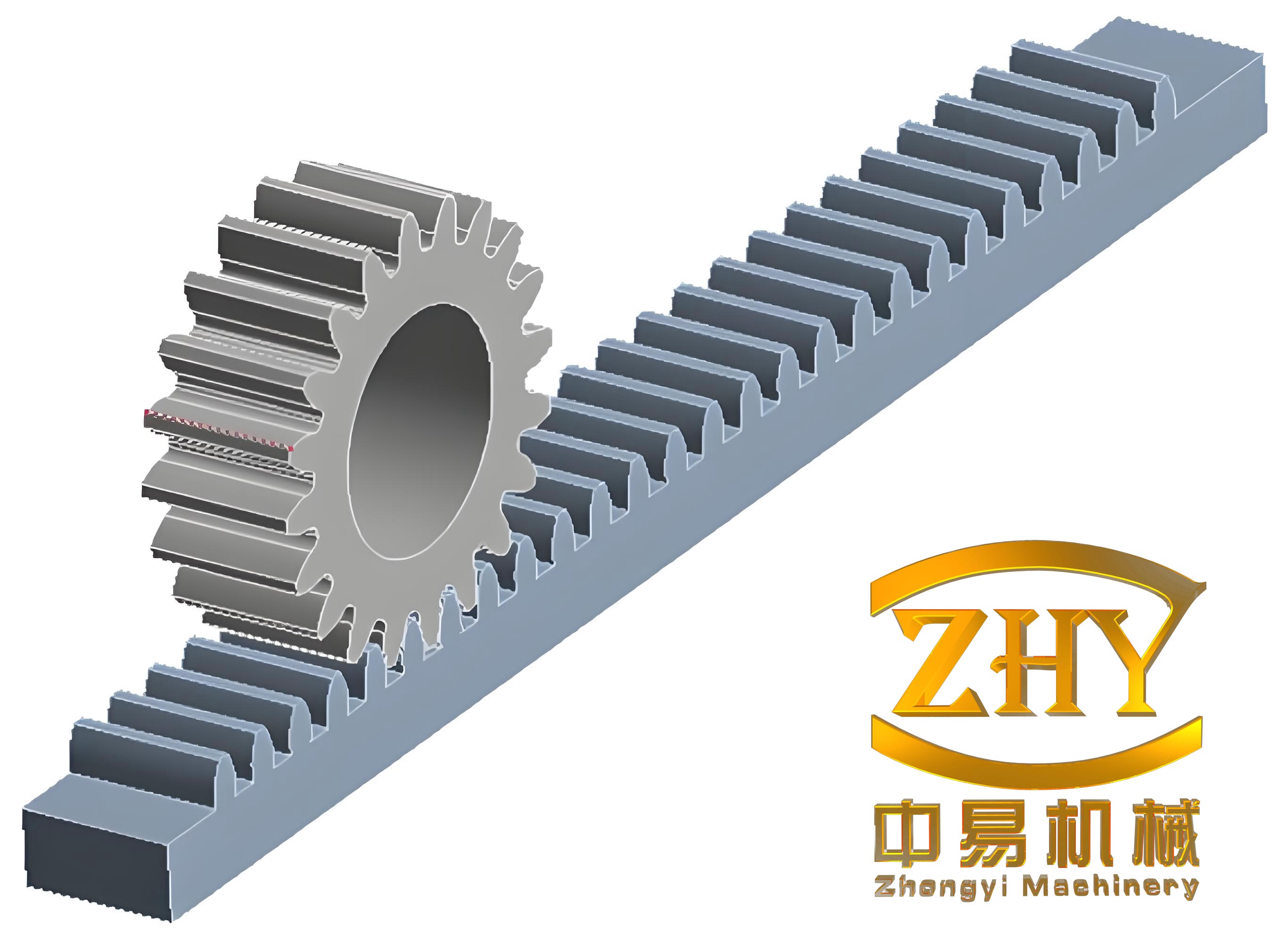

The rack and pinion gear system in steering mechanisms involves a helical gear meshing with a rack to convert rotational motion into linear displacement. Automating this assembly requires precise coordination between multiple axes of motion to avoid interference and ensure proper engagement. In my analysis, I have identified that the rack and pinion gear must be synchronized from the start to prevent collisions, which can lead to component wear, increased noise, and failure in service. The process begins with positioning the rack accurately within the housing, followed by detecting the tooth surface orientation to facilitate smooth insertion of the pinion. This initial step is crucial for the entire rack and pinion assembly, as any misalignment can result in excessive forces or damage. I have developed methods using displacement sensors to locate the rack tooth surface reliably, ensuring consistency across production batches.

To achieve successful assembly, the rack and pinion gear must start from a defined position that allows the pinion teeth to enter the rack slots without interference. Based on my observations, the starting point is determined by the gear displacement L1 and the rack displacement L2, which are derived from the gear helix angles and assembly geometry. For a rack with a right-hand helix angle β, the relationship between L1 and L2 is expressed mathematically as follows:

$$ \frac{L_1}{L_2} = \frac{\cos \beta}{\sin(\alpha + \beta)} $$

where α is the angle between the pinion axis and the vertical direction. Similarly, for a left-hand helix angle γ, the ratio is given by:

$$ \frac{L_1}{L_2} = \frac{1}{\sin \alpha – \cos \alpha \tan \gamma} $$

These equations ensure that the rack and pinion gear move in synchrony during assembly, minimizing the risk of tooth contact before full engagement. In practice, I have implemented servo-driven systems that control the vertical motion of the pinion and the horizontal motion of the rack simultaneously, based on these mathematical models. This synchronization is vital for the rack and pinion system to achieve consistent meshing and avoid the high forces that often plague manual processes. Additionally, I have accounted for variations in rack dimensions, such as those in gradient helix angle racks designed to reduce backlash, by incorporating adaptive control strategies that allow minor rotational adjustments during assembly.

The detection of the rack tooth surface position is a fundamental step in the automatic assembly process for rack and pinion gear systems. I utilize contact-type displacement sensors to measure the distance from the sensor tip to the rack surface as the rack rotates. The sensors identify concave points corresponding to the tooth surfaces, enabling precise angular positioning. For instance, by rotating the rack over 370 degrees, the sensors capture displacement variations, and the minimum points indicate the tooth locations. This data is used to orient the rack at a specific angle, typically 5 degrees from the vertical, to create clearance for the pinion insertion. The process can be summarized with the displacement vector equation for the meshing point motion:

$$ \Delta \mathbf{r} = \Delta x \mathbf{i} + \Delta z \mathbf{k} $$

where Δx represents the horizontal displacement of the rack and pinion, and Δz is the vertical displacement of the pinion. This equation highlights the two-dimensional motion required for synchronous assembly, underscoring the importance of coordinated control in rack and pinion applications.

In the synchronous meshing phase, the rack and pinion gear are driven along their respective paths to achieve full engagement without collision. I have analyzed the contact points between the gear and rack teeth using trajectory modeling, which reveals that interference can occur if the motions are not perfectly synchronized. For gradient helix angle racks, the tooth profile changes along the length, increasing the complexity of assembly. To address this, I have introduced a passive rotation mechanism for the pinion shaft, allowing it to adapt to the rack tooth variations under controlled forces. This reduces the assembly force from potentially over 500 N to around 100–150 N, significantly improving yield rates. The key parameters involved in this process are summarized in the table below, which includes geometric and material properties essential for calculating forces and displacements in rack and pinion gear systems.

| Parameter | Symbol | Typical Value | Description |

|---|---|---|---|

| Pinion Displacement | L1 | 12 mm | Vertical travel of pinion during assembly |

| Rack Displacement | L2 | 6 mm | Horizontal travel of rack during assembly |

| Helix Angle (Right) | β | 5°49’12” | Angle for right-hand rack and pinion |

| Helix Angle (Left) | γ | 5° | Angle for left-hand rack and pinion |

| Pinion Axis Angle | α | Based on design | Angle between pinion axis and vertical |

| Maximum Assembly Force | F | 560 N | Calculated force for pinion bearing press-fit |

Guiding functions play a critical role in ensuring the pinion shaft aligns properly with the bearings during assembly. In my designs, I incorporate导向支撑机构 that provide secondary alignment to compensate for cumulative tolerances in the automation equipment. These guides support the pinion shaft axially and radially, facilitating smooth entry into the bearing bores without scratching or jamming. This is particularly important for the rack and pinion gear system, as the pinion shaft must engage with both needle bearings and deep groove bearings with tight fits. The guiding mechanism reduces the dependency on high-precision machining of the assembly fixtures, thereby lowering costs and improving reliability. For example, the guide centers the shaft end during the press-in process, allowing for minor misalignments without affecting the final assembly quality of the rack and pinion.

Displacement and pressure control are integral to the automatic assembly of rack and pinion gear systems. I employ servo motors for precise displacement control and load cells for real-time force monitoring. The assembly force F for pressing the pinion into the bearings is derived from the interference fit calculations. For a pinion shaft with diameter d_f and length l_f, the force is given by:

$$ F = P_{\text{fmax}} \pi d_f l_f \mu $$

where P_fmax is the maximum contact pressure, and μ is the friction coefficient. The pressure P_fmax is calculated as:

$$ P_{\text{fmax}} = \frac{\delta}{d_f \left( \frac{C_a}{E_a} + \frac{C_i}{E_i} \right)} $$

Here, δ is the maximum interference, C_a and C_i are diameter change coefficients, and E_a and E_i are the elastic moduli of the housing and shaft materials, respectively. For a rack and pinion system with steel components, typical values are E_a = 200 GPa, E_i = 200 GPa, and μ = 0.1 for unlubricated surfaces. The diameter change coefficients depend on the diameter ratios and Poisson’s ratio, as shown in the table below, which aids in determining the press-fit forces for various rack and pinion configurations.

| Diameter Ratio q | C_a (ν=0.3) | C_i (ν=0.3) | Application |

|---|---|---|---|

| 0.57 | 2.214 | 0.7 | Common in rack and pinion bearings |

| 0.5 | 1.967 | 1.367 | General gear assemblies |

| 0.6 | 2.425 | 1.825 | High-load scenarios |

In practice, I set force thresholds based on these calculations to prevent damage during assembly. For instance, if the force exceeds 560 N, the system may halt and flag the component for inspection. This control strategy ensures that the rack and pinion gear are assembled within safe limits, reducing scrap rates and enhancing process capability. Moreover, the integration of displacement sensors allows for continuous monitoring of the rack position, enabling adjustments in real-time to maintain synchronization. The use of these controls has proven effective in achieving consistent meshing gaps and overall quality in rack and pinion systems.

Throughout the development of this automatic assembly process, I have encountered and overcome challenges such as gradient helix angle racks, which require subtle adaptations in the meshing sequence. By allowing the pinion to rotate passively under reduced clamping forces, the system accommodates tooth profile variations without increasing assembly forces. This innovation has led to a significant drop in defect rates, from 2% to below 0.4%, in high-volume production environments. The mathematical models and control algorithms developed for this rack and pinion gear assembly can be adapted to other gear systems, providing a scalable solution for automotive and industrial applications.

In conclusion, the automatic assembly process for rack and pinion gear systems represents a significant advancement in steering mechanism production. My research highlights the importance of precise tooth positioning, synchronous motion control, and adaptive guiding functions to achieve high-quality results. The rack and pinion assembly benefits greatly from automated systems that replicate optimal conditions consistently, leading to improved performance and reduced costs. Future work could explore the integration of artificial intelligence for predictive adjustments and further optimization of the rack and pinion gear interactions. This approach not only addresses current manufacturing needs but also sets a foundation for next-generation assembly technologies in the automotive industry.