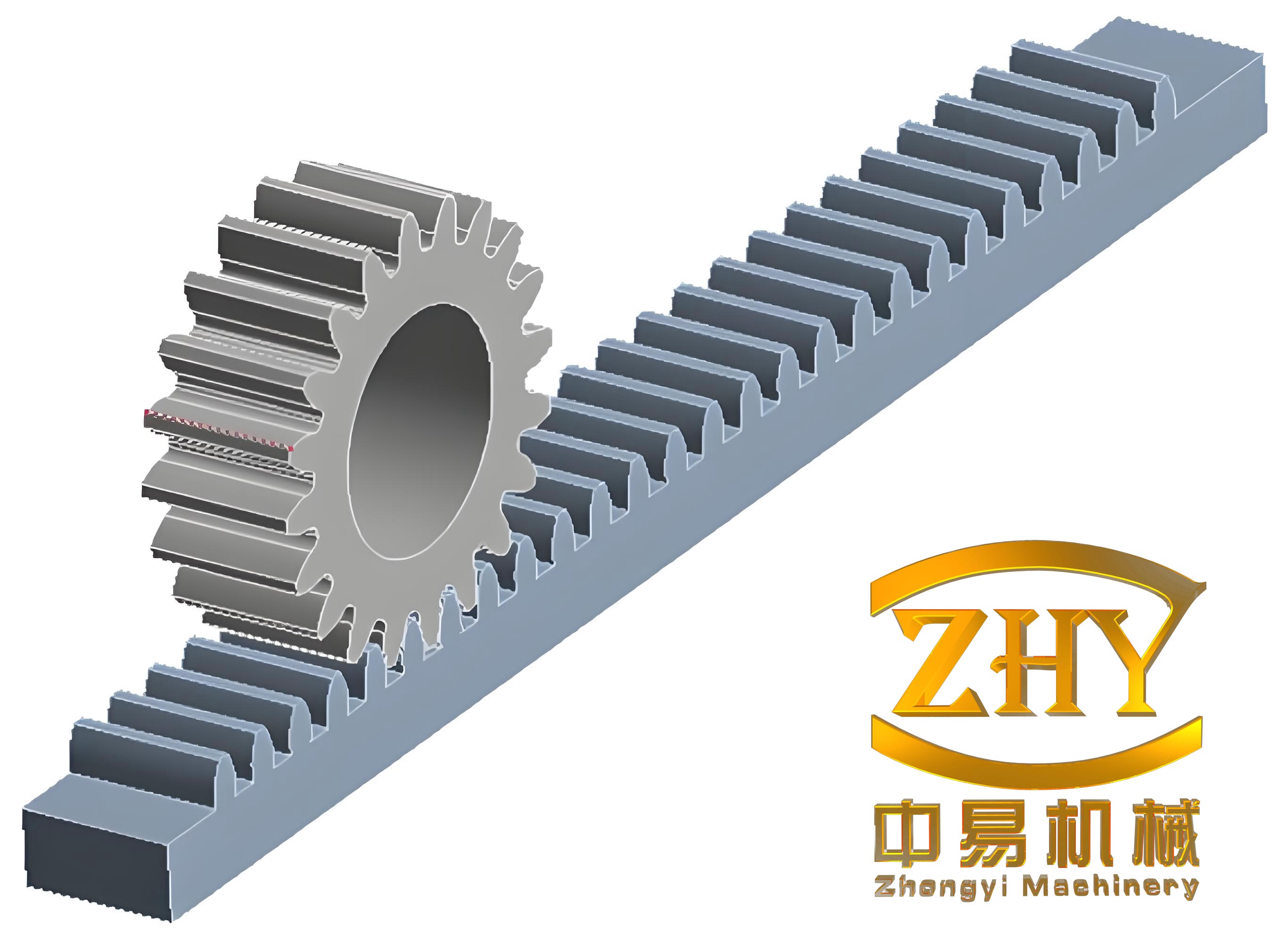

In modern forestry and agricultural practices, the mechanization of seedling transplantation plays a critical role in enhancing efficiency and ensuring the survival rate of trees. Among various mechanisms, the seedling supporting mechanism is pivotal for maintaining the upright posture of seedlings during planting. This study focuses on the design and analysis of a rack and pinion gear-based seedling supporting mechanism specifically for poplar seedlings. The rack and pinion system offers superior linear motion control, which is essential for achieving zero-speed transplantation—a condition where the seedling remains stationary relative to the ground during soil covering and compaction. By leveraging the precise motion characteristics of the rack and pinion gear, we aim to improve the直立度 (uprightness) of seedlings and reduce labor intensity. The mechanism’s design incorporates multiple gears and a rack and pinion arrangement to facilitate reciprocating motion, ensuring consistent support throughout the planting process.

The rack and pinion gear mechanism is chosen for its reliability in transmitting motion and force in a linear fashion. In this design, the rack and pinion system converts rotational input from the transplanter’s ground wheel into linear motion of the seedling support frame. This allows the support frame to move synchronously with the transplanter’s forward velocity but in the opposite direction, thereby stabilizing the seedling upon landing. The use of a rack and pinion gear ensures minimal velocity fluctuations, which is crucial for preventing seedling damage or misalignment. Key parameters, such as the modulus of the rack and pinion gear, are optimized to enhance performance. Below, we present a detailed analysis of the mechanism’s kinematics and dynamics, supported by simulations and mathematical models.

To begin with, we analyze the physical characteristics of fast-growing poplar seedlings, which typically have a length of approximately 300 cm and a ground diameter of 2.7 cm. These parameters influence the design of the rack and pinion seedling supporting mechanism, particularly in terms of the required working stroke and initial positioning. The initial position of the seedling support frame relative to the seedling’s theoretical landing point is calculated to avoid collisions and ensure timely support. The working stroke must accommodate the entire process from seedling landing to soil compaction. The following sections elaborate on the kinematic calculations, dynamic simulations using ADAMS software, and the impact of gear parameters on performance.

Kinematic Analysis of the Rack and Pinion Mechanism

The kinematic analysis involves determining the initial position and working stroke of the seedling support frame. The goal is to achieve zero-speed transplantation, where the seedling’s horizontal velocity is nullified upon landing. The initial gap between the support frame and the seedling’s landing point is derived based on the seedling’s drop time and the transplanter’s forward velocity. Let $v_m$ represent the transplanter’s operational speed (0.439 km/h or 122 mm/s), $H$ the vertical distance from the seedling release point to the ground (assumed as the seedling length for simplicity), and $g$ the acceleration due to gravity (9.8 m/s²). The theoretical drop time $t_1$ and horizontal displacement $l_{OA}$ are given by:

$$H = \frac{1}{2} g t_1^2$$

$$l_{OA} = v_m t_1$$

Solving these equations with $H = 3000$ mm (3 m) yields $t_1 \approx 0.243$ s and $l_{OA} \approx 29.7$ mm. To account for uncertainties, an initial gap $l_{x_0O}$ is introduced, which includes the seedling radius $R$ (12.5 mm) and the maximum allowable gap $e$ for maintaining uprightness. The uprightness requirement, based on a maximum tilt angle $\theta$ of 5°, gives $e = h \cdot \tan(\theta/2)$, where $h = 945$ mm is the vertical distance from the support frame to the landing point. Thus, $e \approx 41.2$ mm, and the initial gap is:

$$l_{x_0O} = l_{OA} + R + e \approx 83.4 \text{ mm}$$

The working stroke $S$ of the rack and pinion mechanism must cover this initial gap plus the distance to the soil compaction point. If $l_{OB} = 445.0$ mm is the distance from the seedling release point to the compactor’s center, and $l_{Bx_1} = 40.0$ mm is the additional distance for post-compaction support, the total required stroke $S_0$ is:

$$S_0 = l_{x_0O} + l_{OB} + l_{Bx_1} \approx 568.4 \text{ mm}$$

In the rack and pinion gear system, the theoretical stroke $S$ is determined by the geometry of the sector gears and the rack. For a sector gear with pitch diameter $d$ and engagement angle $\alpha$, the stroke is approximated as:

$$S = \frac{2\alpha + \beta}{360} \pi d$$

where $\beta$ is the sector angle. However, due to dynamic effects like gear meshing impacts, the actual stroke may exceed this value, as verified in simulations.

Dynamic Simulation Using ADAMS

We employ ADAMS software to simulate the dynamics of the rack and pinion seedling supporting mechanism. The simulation model includes multiple components: the rack and pinion gear, sector gears, sliding rails, and the seedling support frame. Contact forces between gears and the rack are modeled using the Impact function, which combines Hertzian contact theory with damping effects. The normal contact force $F_n$ is given by:

$$F_n = \begin{cases}

K \delta^q + \text{STEP}(\delta, 0, 0, d_{\text{max}}, C_{\text{max}}) \frac{d\delta}{dt} & \delta \geq 0 \\

0 & \delta < 0

\end{cases}$$

Here, $K$ is the contact stiffness, $\delta$ the penetration depth, $q$ the force exponent (1.5 for metals), $d_{\text{max}}$ the maximum penetration (0.1 mm), and $C_{\text{max}}$ the damping coefficient (100 N·s/mm). The tangential force $F_s$ incorporates Coulomb friction:

$$F_s = -F_n \times \text{STEP}(v_t, -v_s, -1, v_s, 1) \times \text{STEP}(|v_t|, v_s, f_{\text{st}}, v_d, f_{\text{dy}})$$

where $v_t$ is the relative slip velocity, $v_s$ and $v_d$ are static and dynamic friction thresholds, and $f_{\text{st}}$ and $f_{\text{dy}}$ are friction coefficients (0.08 and 0.05, respectively).

The simulation parameters are summarized in the table below, highlighting key aspects of the rack and pinion gear system.

| Parameter | Value |

|---|---|

| Transplanter Speed | 0.439 km/h |

| Input Shaft Speed | 6.18 rpm |

| Rack and Pinion Modulus | 7, 8, 9, 10 (varied) |

| Contact Stiffness $K$ | 1.714 × 10^5 N/mm^{3/2} |

| Damping Coefficient $C_{\text{max}}$ | 100 N·s/mm |

| Material | 45 Steel (Elastic Modulus 210 GPa) |

The simulation assesses the effect of the rack and pinion gear modulus on the seedling support frame’s velocity and displacement. For instance, a modulus of 9 results in the most stable motion, with velocity fluctuations minimized after an initial transient phase. The displacement of the support frame over time is nearly linear, indicating uniform motion at approximately 122 mm/s. The actual working stroke achieved in simulation is 599.9 mm, exceeding the required 568.4 mm, thanks to dynamic interactions in the rack and pinion system.

Furthermore, the angular velocities of the driving gears remain stable, with minor oscillations due to initial meshing impacts. The maximum contact force in the rack and pinion gear engagement is 512.6 N, which is well within the material strength limits, ensuring no tooth failure or excessive wear. This demonstrates the robustness of the rack and pinion design in transmitting power efficiently.

Results and Discussion

The simulation results confirm that the rack and pinion seedling supporting mechanism meets the requirements for poplar seedling transplantation. The rack and pinion gear system provides a smooth, linear motion that aligns with the transplanter’s velocity, enabling zero-speed conditions. Key performance metrics are outlined in the table below, emphasizing the role of the rack and pinion parameters.

| Metric | Value |

|---|---|

| Optimal Modulus | 9 |

| Support Frame Velocity | 122 mm/s (steady state) |

| Working Stroke | 599.9 mm |

| Max Meshing Force | 512.6 N |

| Gear Speed Stability | High (minimal fluctuations) |

The use of a rack and pinion gear ensures that the seedling support frame moves in a synchronized manner, reducing the risk of seedling tilting. The dynamics of the rack and pinion interaction are critical; for example, the initial engagement between the sector gears and the rack involves impact forces that are effectively managed through proper damping. The rack and pinion mechanism’s ability to maintain constant velocity over the working stroke is a significant advantage over alternative designs, such as linkage-based systems, which may introduce unwanted accelerations.

In terms of design implications, the modulus of the rack and pinion gear directly influences the tooth size and load capacity. A modulus of 9 strikes a balance between strength and smooth operation, as evidenced by the stable velocity profiles in simulation. The rack and pinion system’s simplicity also facilitates manufacturing and maintenance, making it suitable for field applications in forestry machinery.

Conclusion

In this study, we have designed and analyzed a rack and pinion seedling supporting mechanism for poplar seedling transplanters. The rack and pinion gear system proves effective in achieving zero-speed transplantation by providing a linear, reciprocating motion that stabilizes seedlings during soil covering. Kinematic calculations ensure proper initial positioning and working stroke, while dynamic simulations validate the mechanism’s performance under operational conditions. The rack and pinion design outperforms other mechanisms in terms of motion stability and reliability, with the optimal modulus of 9 yielding the best results. Future work could involve prototyping and field tests to further refine the rack and pinion parameters for varying soil conditions and seedling types. Overall, the rack and pinion approach offers a promising solution for enhancing the efficiency and success rate of mechanized seedling transplantation in forestry.