In the development of transmission systems for new energy vehicles, my focus was on a critical powertrain component: a pair of crossed-axis worm gears. Compared to traditional transmissions, the new energy E P21 gearbox utilizes these worm gears to achieve motion conversion and torque amplification within the bearing housing. This is a spatial mechanism for transmitting motion between non-parallel, non-intersecting shafts, typically at a 90° axis angle. This type of gearing is favored for its compact structure and high reduction ratio. Furthermore, the multiple tooth pairs in simultaneous contact provide high overlap, resulting in exceptionally smooth and quiet operation. However, the inherent complexity and high precision requirements of manufacturing both the worm and the wheel posed a significant technical challenge. This analysis details the journey from design parameters to a validated manufacturing process for these specific worm gears.

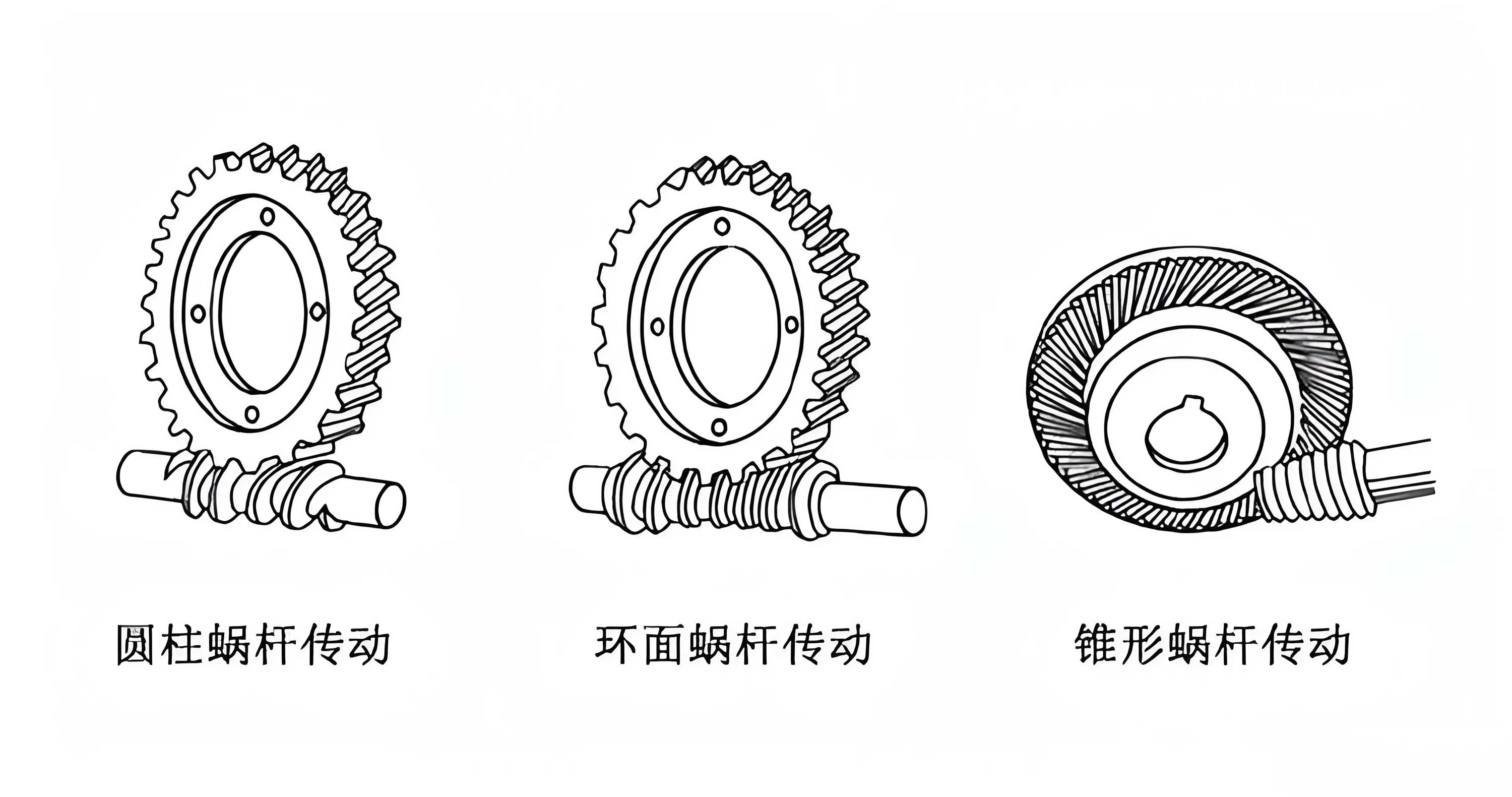

The worm gear mechanism is a vital transmission component in mechanical systems. Among various types, the cylindrical worm drive, with its spiral tooth surface that is relatively easier to machine, is most commonly used. Based on the tool setup and machining method, cylindrical worms are categorized into four primary types: ZA (Archimedes), ZN (Normal Straight-Sided), ZI (Involute), and ZK (Cone Enveloping). The subject of this process is the ZN-type worm. Its tooth surface is a ruled surface, generated by a straight cutting edge situated in the normal plane relative to the worm axis undergoing a helical motion. The flank profile in the axial section is a convex curve, while the tooth space profile in the normal section is a straight line. This characteristic straight-line profile in the normal section of the tooth space is central to the tooling and machining strategy employed.

The successful machining of these worm gears begins with a precise understanding of their design parameters. The geometric specifications dictate every subsequent step in the manufacturing sequence. The core parameters for the worm and worm wheel pair are as follows:

| Parameter | Worm | Worm Wheel |

|---|---|---|

| Module (m) | 1.25 mm | 1.25 mm |

| Number of Threads / Teeth (Z) | Z₁ = 2 (Threads) | Z₂ = 60 (Teeth) |

| Normal Pressure Angle (αₙ) | 20° | 20° |

| Diameter Factor (q) | 10 | — |

| Lead Angle (γ) | γ = arctan(Z₁ / q) = 11.31° | — |

| Hand of Spiral | Right Hand | Right Hand |

| Addendum Coefficient (hₐ*) | 1 | — |

| Pitch Diameter (d) | d₁ = m * q = 12.5 mm | d₂ = m * Z₂ = 75 mm |

| Profile Shift Coefficient (x) | 0 | x₂ = +0.2 |

From these fundamental parameters, key dimensions for machining are derived. The axial pitch of the worm is the foundation for thread spacing:

$$P_x = \pi m = \pi \times 1.25 \approx 3.927 \text{ mm}$$

The lead of the worm, which is the axial distance the thread advances in one complete revolution, is:

$$P_z = P_x \times Z_1 = 3.927 \times 2 = 7.854 \text{ mm}$$

This lead value is critical for setting up the helical motion during both the turning and grinding of the worm threads.

Based on the component characteristics and material properties, distinct yet interlinked process routes were established for the worm shaft and the worm wheel. The guiding principle was to progress from rough shaping to final precision finishing, incorporating necessary heat treatment for the worm to achieve the required surface durability. The overall process flow is summarized below:

| Component | Primary Process Route |

|---|---|

| Worm Shaft (Material: 40Cr Alloy Steel) |

Material Preparation → Blank Turning → Rough Turning → Finish Turning → Milling (Secondary Features) → Heat Treatment (Case Hardening) → Cylindrical Grinding → Thread/Tooth Profile Grinding → Final Inspection. |

| Worm Wheel (Material: ZCuSn10Pb1 Tin Bronze) |

Material Preparation → Blank Turning → Rough Turning → Finish Turning → Drilling → Rough/Finish Turning (OD) → Slot Milling → Gear Hobbing → Finishing Milling → Final Inspection. |

The machining of the ZN-type worm presented specific challenges, particularly in generating the correct tooth profile. The material, 40Cr alloy steel, was selected for its core strength and its suitability for subsequent case hardening to achieve a surface hardness of 45-55 HRC, essential for wear resistance in the worm gears pair.

The most critical phase was the finish turning of the thread profile. The defining feature of the ZN-type worm is that the tooth space profile in the normal section is a straight line. At the pitch line height, the tooth thickness and the space width are equal, each being half of the axial pitch:

$$ s_n = e_n = 0.5 \times P_x \approx 1.9635 \text{ mm} $$

To achieve this, a standard turning insert was specially reground to replicate this straight-sided normal profile geometry. During the turning operation on the CNC lathe, the tool was meticulously aligned to cut in the normal plane of the worm’s thread space. The process involved first machining one helical thread to near-final dimensions, leaving a defined grinding allowance. The setup was then indexed to machine the opposite flank of the same thread, followed by the same sequence for the second start (thread) of the double-lead worm. This method ensured the correct spatial relationship between the two threads of the worm.

The final accuracy of the hardened worm’s tooth profile was achieved through precision grinding. The form accuracy is directly dependent on the profile of the grinding wheel. A diamond dressing tool was used to accurately shape the grinding wheel. The worm was mounted between centers and carefully aligned. The grinding wheel was then fed axially along the workpiece to finish the hardened tooth flanks. This process produced the final, high-precision threads ready for assembly in the worm gears assembly.

The manufacturing of the mating worm wheel required a different approach due to its bronze material, which is chosen for its excellent conformability and load-bearing characteristics against the hardened steel worm. The core process is gear hobbing. A dedicated fixture was designed to accurately locate and hold the worm wheel blank via its central bore. A custom-designed and manufactured worm wheel hob, matching the exact parameters of the mating worm (including the profile shift coefficient x₂ = +0.2), was used. Prior to cutting, the hob axis was precisely aligned. The hobbing operation was performed using a radial infeed method, where the hob feeds directly into the workpiece from the outside diameter towards the center. An infeed rate of 0.03 to 0.05 mm per revolution of the workpiece was used, progressively cutting from the tooth tip to the full depth. This method is highly efficient and provides good surface quality for bronze worm gears.

The quality of the finished worm gears pair was validated through comprehensive inspection. For the worm, critical parameters like lead error, profile deviation, and pitch consistency were measured using specialized gear and thread measuring equipment. For the worm wheel, gear inspection equipment was used to generate reports on adjacent pitch error, cumulative pitch error, runout, and most importantly, the tooth flank form (profile) and alignment (lead). The scan of the worm wheel’s tooth surface confirmed that the actual meshing geometry aligned with the theoretical design, ensuring optimal contact pattern and performance for the final worm gears assembly. All measured parameters fell within the stringent specified tolerances, validating the effectiveness of the entire manufacturing process sequence.

In conclusion, this detailed process analysis for the ZN-type worm and worm wheel pair demonstrates a successful translation of design intent into a reliable manufacturing reality. By deeply analyzing the geometric characteristics of these specific worm gears, a tailored process plan was developed. This plan encompassed specialized tooling, such as the reground turning tool for the ZN profile and the custom hob, along with dedicated fixtures for precise location. The selection of appropriate materials and heat treatment, coupled with sequential roughing, finishing, and final precision grinding or hobbing operations, proved effective. The final inspection results, confirming all critical parameters, underscore that the developed methodology is robust. This systematic approach, from parameter analysis through process design to validation, provides a reliable framework and practical reference for the machining of similar high-precision worm gears components in advanced automotive and other precision engineering applications. The experience gained reinforces the principle that mastering the unique geometry of components like worm gears is the key to unlocking their manufacturing potential.