In this article, I explore the application of strain wave gear, also known as harmonic gear drive, in industrial robotics, focusing on its design principles, operational advantages, and precision challenges. The strain wave gear, invented in the mid-20th century, represents a paradigm shift in mechanical transmission by utilizing elastic deformation of flexible components rather than rigid bodies. This innovation has become a cornerstone in modern industry, particularly in robotics, where over 60% of strain wave gear systems are deployed. I will delve into the structural aspects, working mechanisms, and key factors affecting motion accuracy, incorporating tables and mathematical formulas to summarize critical points. The discussion is based on a review of existing technologies and design philosophies, aiming to address issues in design, assembly, and production line applications.

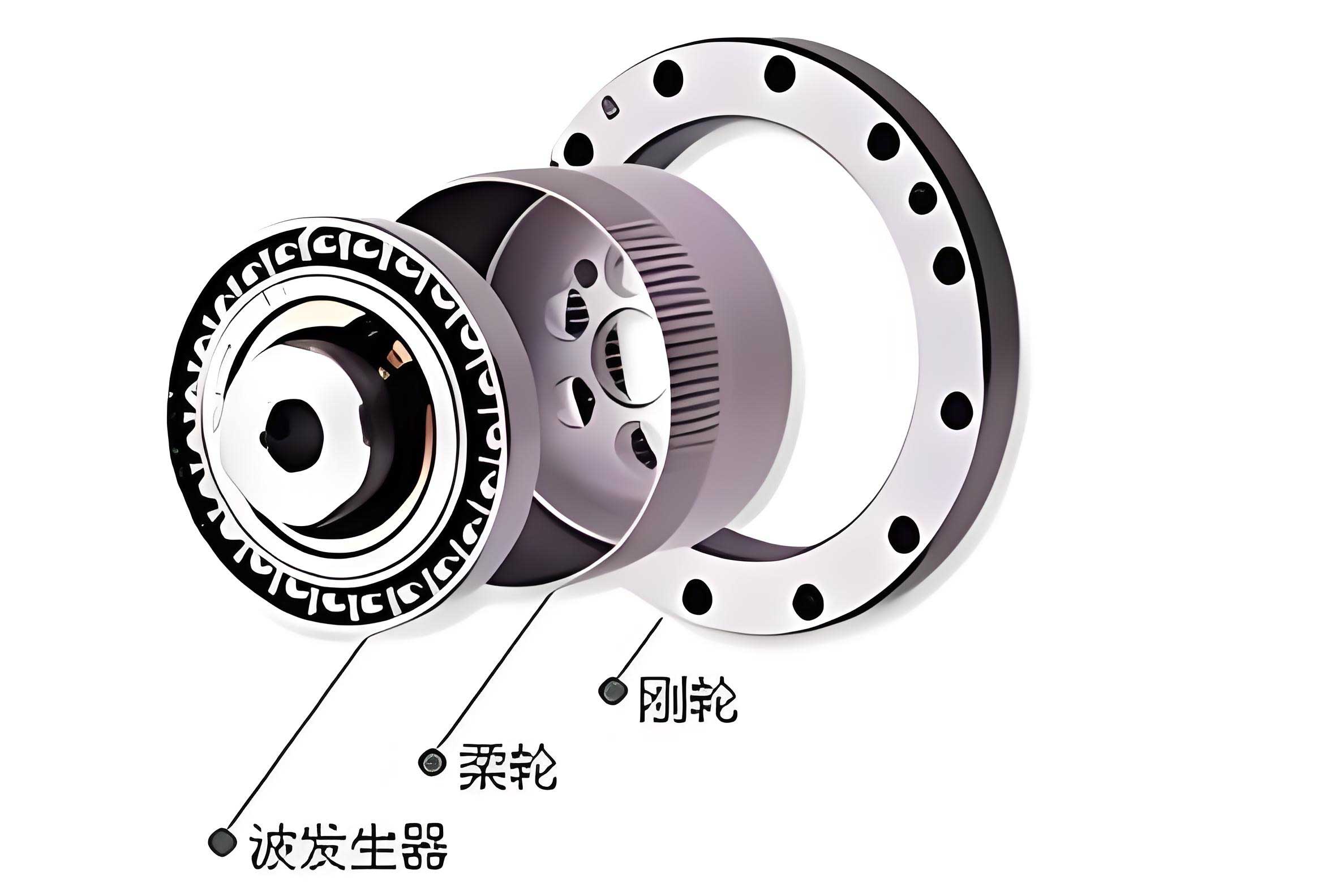

The strain wave gear system is composed of three primary components: the wave generator, the flexspline (flexible wheel), and the circular spline (rigid wheel). By fixing any one of these components and using the remaining two as input and output, one can achieve speed reduction or increase with a fixed transmission ratio. Alternatively, a differential transmission can be configured with two inputs and one output. The unique ability to deform the flexspline enables controlled engagement with the circular spline, facilitating high-precision motion transfer.

To understand the working principle, consider the strain wave gear as a system where the wave generator, often a cam or elliptical component, induces a traveling deformation wave in the flexspline. This wave causes the teeth of the flexspline to engage and disengage with those of the circular spline cyclically. Specifically, at the major axis of the wave generator, the teeth are fully engaged, while at the minor axis, they are completely disengaged. As the wave generator rotates continuously, driven by a motor, the flexspline undergoes repeated elastic deformation, leading to a sequence of meshing states: entry, engagement, exit, and disengagement. This “missed tooth” motion results in a high reduction ratio, converting high-speed input into low-speed output. The process can be described mathematically by the deformation function of the flexspline. Let the radial displacement of the flexspline be modeled as a wave function:

$$ u(\theta, t) = A \cos(n\theta – \omega t) $$

where \( u \) is the radial deformation, \( A \) is the amplitude, \( n \) is the wave number (typically 2 for common strain wave gears), \( \theta \) is the angular position, \( \omega \) is the angular velocity of the wave generator, and \( t \) is time. This deformation enables the transmission of motion with minimal backlash.

The characteristics of strain wave gear systems make them ideal for robotics. Compared to traditional gear systems, they offer superior performance in terms of compactness, weight, and precision. I summarize these advantages in Table 1, highlighting why strain wave gear is preferred in robotic applications.

| Feature | Strain Wave Gear | Traditional Gear (e.g., Spur Gear) |

|---|---|---|

| Weight | Lightweight due to flexible components | Heavier rigid structures |

| Volume | Compact design | Bulkier assembly |

| Transmission Ratio | High (e.g., 50:1 to 160:1 in single stage) | Lower per stage |

| Efficiency | High (up to 90%) | Varies, often lower |

| Backlash | Minimal, often near zero | Significant, requires compensation |

| Coaxiality | Excellent | Moderate |

| Application in Robotics | Widespread (>60% usage) | Limited to specific joints |

In industrial robotics, the strain wave gear serves as a core component for motion functionality, enabling reliable and precise operation in lightweight arms and manipulators. Robots are automated machines capable of executing programmed tasks, and industrial robots, in particular, are multi-jointed mechanical arms with multiple degrees of freedom. They consist of three main parts: mechanical structure, sensing system, and control system, further divided into six subsystems: mechanical structure system, drive system, perception system, control system, human-robot interaction system, and environment interaction system. I focus on the drive and mechanical structure systems, where strain wave gear plays a pivotal role.

The drive system of a robot provides actuation through various means, such as hydraulic, pneumatic, or mechanical transmission. Strain wave gear is often used in mechanical drive systems for indirect actuation, offering precise control and high torque density. For instance, in a five-degree-of-freedom (5-DOF) mechanical arm, strain wave gear drives are employed to achieve compact and efficient motion. The 5-DOF arm typically includes axes for arm elevation, shoulder extension, tilt, wrist rotation, and gripper actuation. Each joint requires a tailored transmission solution, and strain wave gear is commonly used in rotational joints due to its high reduction ratio and precision.

Analyzing a specific 5-DOF mechanical arm design, the strain wave gear is integrated into key joints such as the shoulder, elbow, and wrist. The arm uses a three-axis suspension mechanism plus a wrist segment to achieve five degrees of freedom in three-dimensional space. The waist rotation is driven by a DC motor with a primary gear reduction, while the pitch motions of the upper arm, forearm, and small arm are realized through strain wave gear transmissions. The wrist rotation employs a two-stage gear system with a strain wave gear primary stage. This design minimizes space occupation and enhances agility, making it suitable for confined workspaces. The use of strain wave gear in the first joint, which bears the largest load and requires high torque for start-stop cycles, is critical due to its high torque capacity and precision.

The motion precision of strain wave gear systems is a key concern in robotics. Transmission error, defined as the deviation between the actual and theoretical output positions, is a primary metric. It arises from manufacturing and assembly inaccuracies in the wave generator, flexspline, and circular spline. The strain wave gear benefits from multiple tooth pairs engaging simultaneously, which compensates for errors to some extent, resulting in lower motion error compared to conventional gears. However, various error sources still impact performance. I list these error sources and their effects in Table 2.

| Error Source | Component Affected | Effect on Transmission Error |

|---|---|---|

| Pitch Error | Circular Spline and Flexspline | Linear increase in error amplitude |

| Eccentricity | Wave Generator and Flexspline | Low-frequency error components |

| Tooth Profile Deviation | Flexspline Teeth | High-frequency harmonics |

| Assembly Misalignment | All Components | Increased backlash and stiffness variation |

| Elastic Deformation Variation | Flexspline Material | Non-linear error under load |

Mathematically, the transmission error \( \Delta \theta \) can be modeled as a function of individual errors. For instance, based on elastic deformation theory, the error due to pitch variations in the circular spline can be expressed as:

$$ \Delta \theta_p = \sum_{i=1}^{N} \frac{\Delta p_i}{r} \cos(\phi_i) $$

where \( \Delta p_i \) is the pitch error for tooth \( i \), \( r \) is the reference radius, \( \phi_i \) is the angular position, and \( N \) is the number of teeth. Similarly, eccentricity errors introduce sinusoidal components:

$$ \Delta \theta_e = e \sin(\omega t + \psi) $$

with \( e \) as the eccentricity magnitude and \( \psi \) as the phase angle. The total transmission error is often a superposition of such terms, leading to complex error spectra.

Error testing for strain wave gear systems typically involves dynamic measurement to capture both low- and high-frequency components. Static tests may only reveal low-frequency errors, but dynamic systems can assess real-time performance. The error curve of a strain wave gear often exhibits a “beat frequency” phenomenon, where two error frequencies with small differences interfere, creating a modulated pattern. This occurs when eccentricities in the circular spline and flexspline produce error frequencies \( f_1 \) and \( f_2 \) that are close, resulting in a beat frequency \( f_b = |f_1 – f_2| \). The error amplitude modulation can be described as:

$$ E(t) = A_1 \sin(2\pi f_1 t) + A_2 \sin(2\pi f_2 t) $$

which simplifies to a beat pattern when \( A_1 \approx A_2 \). This phenomenon complicates error analysis and necessitates advanced testing methodologies.

Furthermore, the stiffness of a strain wave gear system influences its precision under load. The torsional stiffness \( K_t \) can be derived from the elastic properties of the flexspline and engagement conditions. A simplified model gives:

$$ K_t = \frac{T}{\Delta \theta_l} = \frac{E I n^2}{R^3} $$

where \( T \) is the torque, \( \Delta \theta_l \) is the angular deflection under load, \( E \) is Young’s modulus, \( I \) is the moment of inertia of the flexspline cross-section, \( n \) is the wave number, and \( R \) is the mean radius. This stiffness affects the system’s response to dynamic loads in robotics, such as during rapid accelerations or payload changes.

In addition to precision, the design and manufacturing of strain wave gear systems require careful consideration. The flexspline, often made of high-strength alloy steel, undergoes heat treatment and precise machining to ensure durability and elasticity. The wave generator may use ball bearings or specialized cams to minimize friction. Advanced manufacturing techniques, such as CNC grinding and laser measurement, are employed to achieve tight tolerances. I summarize key design parameters in Table 3, which influence the performance of strain wave gear in robotic applications.

| Parameter | Typical Range | Impact on Performance |

|---|---|---|

| Module (Gear Size) | 0.1 to 1 mm | Affects torque capacity and compactness |

| Number of Teeth (Flexspline) | 100 to 300 | Determines reduction ratio and smoothness |

| Wave Generator Type | Cam, Elliptical, or Disk | Influences deformation pattern and efficiency |

| Flexspline Wall Thickness | 0.5 to 2 mm | Balances flexibility and strength |

| Material Hardness | HRC 50-60 for flexspline | Enhances wear resistance and fatigue life |

| Lubrication Method | Grease or Oil Bath | Reduces friction and heat generation |

The widespread use of strain wave gear in robotics is evident in examples like Honda’s ASIMO humanoid robot, which incorporates over 24 strain wave gear units in its limbs, and NASA’s Mars rovers, utilizing 19 units per robot for precise articulation. These applications underscore the reliability and precision of strain wave gear systems in demanding environments. As robotics evolves toward more dexterous and autonomous systems, the demand for high-performance strain wave gear is expected to grow.

Looking ahead, trends in strain wave gear technology include miniaturization for micro-robotics, integration with direct-drive motors, and smart materials for adaptive flexibility. Research is also focusing on error compensation algorithms using real-time sensor feedback to enhance accuracy. For instance, machine learning models can predict transmission errors based on load and temperature data, enabling corrective actions in control systems.

In conclusion, the strain wave gear is an indispensable component in industrial robotics, offering unmatched advantages in compactness, precision, and efficiency. Through detailed analysis of its structure, working principles, and precision factors, I have highlighted its critical role in enabling advanced robotic functionalities. The use of tables and mathematical models helps summarize complex aspects, from error sources to design parameters. As robotics continues to advance, driven by innovations in artificial intelligence and automation, the strain wave gear will remain a key enabler, pushing the boundaries of what machines can achieve. Future work should address manufacturing challenges and explore hybrid systems combining strain wave gear with other transmission technologies for even greater performance.