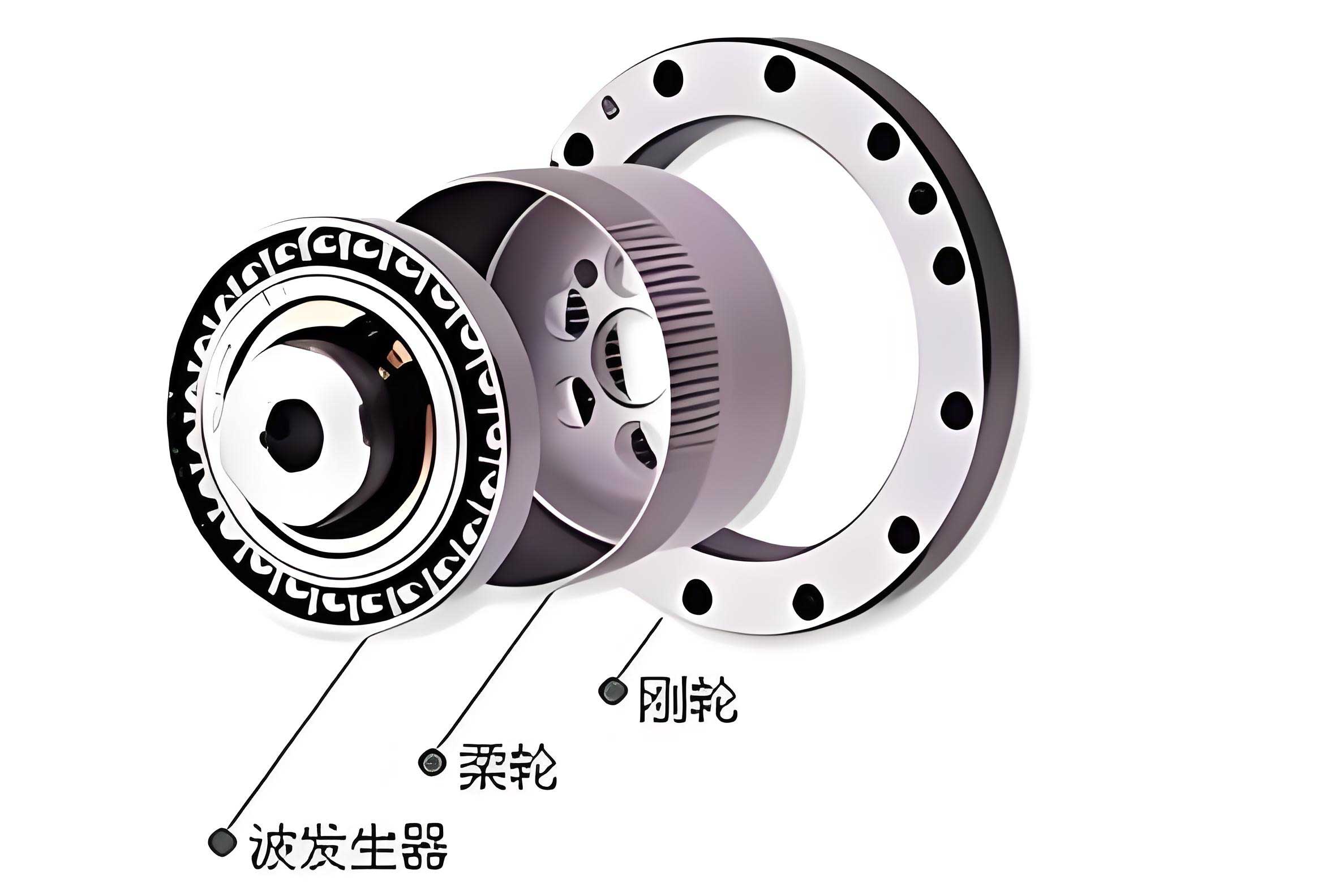

The advancement of modern industry, particularly in fields such as aerospace, robotics, and precision instrumentation, has consistently demanded compact, high-ratio, and high-precision transmission solutions. Among these, the strain wave gear, also known as a harmonic drive, stands out as a pivotal technology. Its unique operating principle, which relies on the elastic deformation of a flexible spline, enables exceptional performance characteristics including high reduction ratios in a single stage, near-zero backlash, high positional accuracy, and compactness. The genesis of the strain wave gear concept dates back to the mid-20th century, and its subsequent development and refinement have been driven by the need for reliable and precise motion control in demanding applications. The core of its performance lies in the meshing interaction between the non-deformable circular spline and the elliptically deformed flexspline. Therefore, the design of the tooth profile for both components is paramount, directly influencing the transmission’s load capacity, torsional stiffness, motion accuracy, and service life.

Traditional tooth profiles for strain wave gears have evolved from involute shapes to various arc-based profiles to improve load distribution and manufacturability. The double-circular-arc profile has been widely studied and applied. However, recent research has proposed a triple-circular-arc profile for the flexspline, which consists of three tangentially connected circular arcs: a convex arc at the addendum, a concave arc at the dedendum, and a middle transition arc. Preliminary studies suggest that this triple-arc profile offers a wider conjugate meshing zone and superior contact conditions compared to its double-arc counterpart. This article delves into a comprehensive meshing performance analysis of a strain wave gear utilizing this triple-circular-arc flexspline tooth profile. The analysis encompasses the derivation of the conjugate circular spline profile, evaluation of theoretical conjugate deviations, calculation of meshing overlap, determination of maximum tooth engagement depth, and a detailed investigation of the transmission backlash. All discussions are framed within the fundamental principles of strain wave gearing.

1. Kinematic Model and Coordinate Systems for Strain Wave Gearing

To analytically describe the complex spatial meshing process in a strain wave gear, it is standard practice to simplify the problem into a planar analysis. This involves making several key assumptions: (1) the meshing between the circular spline, flexspline, and wave generator is treated as a planar gear engagement; (2) the neutral curve of the flexspline does not elongate during deformation; and (3) the teeth of both the flexspline and circular spline are considered rigid bodies, neglecting tooth deflection during the kinematic analysis. These assumptions allow for the establishment of clear coordinate systems to quantify the relative motion and positions.

For a strain wave gear employing an elliptical wave generator, the following coordinate systems are established, as conceptually represented in the analysis:

$$ S_f(X_f, O_f, Y_f) $$: A coordinate system fixed to the flexspline tooth.

$$ S_0(X_0, O_0, Y_0) $$: A coordinate system fixed to the flexspline body.

$$ S_1(X_1, O_1, Y_1) $$: A coordinate system fixed to the circular spline.

$$ S_2(X_2, O_2, Y_2) $$: A coordinate system fixed to the wave generator.

The relationship between these systems is governed by the wave generator’s geometry. For an elliptical wave generator, the radial deformation of the flexspline’s neutral curve is often approximated by:

$$ \rho(\varphi) = r_0 + \omega_0 \cos(2\varphi) $$

where \( r_0 \) is the nominal radius of the neutral curve before deformation, \( \omega_0 \) is the radial deformation amplitude, and \( \varphi \) is the angular coordinate relative to the major axis of the ellipse. The transformation matrices between these coordinate systems are crucial for solving the conjugate tooth profiles.

2. Flexspline Triple-Arc Tooth Profile Definition

The proposed triple-circular-arc profile for the flexspline is defined in its own tooth coordinate system \( S_f \). The profile is composed of three circular arcs: the addendum convex arc \( \overset{\frown}{AB} \), the middle arc \( \overset{\frown}{BC} \), and the dedendum concave arc \( \overset{\frown}{CD} \). These arcs are tangently connected at points B and C.

The key geometric parameters defining this profile are listed in the following table:

| Parameter | Symbol | Description |

|---|---|---|

| Addendum Convex Arc Radius | \( \rho_a \) | Radius of the arc from point A to B. |

| Middle Arc Radius | \( \rho_m \) | Radius of the transitional arc from point B to C. |

| Dedendum Concave Arc Radius | \( \rho_f \) | Radius of the arc from point C to D. |

| Addendum Height | \( h_a \) | Tooth addendum height from the pitch line. |

| Dedendum Height | \( h_f \) | Tooth dedendum height from the pitch line. |

| Convex Arc Center Offset | \( y_a \) | Vertical offset of the convex arc center. |

| Tangential Angle at B | \( \delta_1 \) | Angle of the common tangent at point B relative to the Y-axis. |

| Tangential Angle at C | \( \delta_2 \) | Angle of the common tangent at point C relative to the Y-axis. |

| Distance to Neutral Layer | \( d_s \) | Distance from the tooth root circle to the flexspline’s neutral layer. |

Based on these parameters and geometric continuity conditions (tangency at B and C), the center coordinates for each arc can be derived. Let \( O_{a}(x_{a}, y_{a}) \), \( O_{m}(x_{m}, y_{m}) \), and \( O_{f}(x_{f}, y_{f}) \) be the centers of arcs AB, BC, and CD respectively in \( S_f \). Their coordinates are calculated as follows:

$$ x_a = 0 $$

$$ y_a = h_f + d_s – y_a $$

$$ x_m = \rho_a \cos \delta_1 + x_a – \rho_m \cos \delta_1 $$

$$ y_m = \rho_a \sin \delta_1 + y_a – \rho_m \sin \delta_1 $$

$$ x_f = \rho_m \cos \delta_2 + x_m – \rho_f \cos \delta_2 $$

$$ y_f = \rho_m \sin \delta_2 + y_m – \rho_f \sin \delta_2 $$

Using the arc length \( s \) as a parameter, the position vector \( \mathbf{r}(s) \) and unit normal vector \( \mathbf{n}(s) \) for any point on the flexspline profile can be expressed piecewise for each arc segment, forming a discrete point matrix for numerical analysis.

3. Conjugate Circular Spline Tooth Profile Generation

The fundamental requirement for a functional strain wave gear is that the circular spline tooth profile must be conjugate to the flexspline profile undergoing wave generator-induced motion. The conjugate profile is not a simple copy but is generated based on the kinematic path of the flexspline teeth relative to the circular spline. The precise mathematical method involves coordinate transformations and the meshing equation.

The coordinate transformation matrix \( \mathbf{M}_{10} \) from the flexspline body system \( S_0 \) to the circular spline system \( S_1 \), and its associated rotation matrix \( \mathbf{W}_{10} \), incorporate the wave generator motion parameters (rotation angle \( \beta \)) and the radial deformation function \( \rho(\varphi) \).

$$ \mathbf{M}_{10} = \begin{bmatrix}

\cos \beta & \sin \beta & \rho(\varphi) \sin(\varphi – \beta) \\

-\sin \beta & \cos \beta & \rho(\varphi) \cos(\varphi – \beta) \\

0 & 0 & 1

\end{bmatrix} $$

$$ \mathbf{W}_{10} = \begin{bmatrix}

\cos \beta & -\sin \beta & 0 \\

\sin \beta & \cos \beta & 0 \\

0 & 0 & 1

\end{bmatrix} $$

The meshing equation, which dictates the condition for contact between two profiles, states that the relative velocity at the contact point must be orthogonal to the common surface normal. In the context of the strain wave gear, this can be expressed as:

$$ \mathbf{n}^T \cdot \mathbf{v}^{(01)} = 0 $$

where \( \mathbf{n} \) is the normal vector at a point on the flexspline profile (transformed appropriately) and \( \mathbf{v}^{(01)} \) is the relative velocity of that point with respect to the circular spline. This leads to the formulation of a meshing invariant matrix \( \mathbf{B} \):

$$ \mathbf{B} = \mathbf{W}_{10}^T \frac{d\mathbf{M}_{10}}{dt} $$

and the final meshing condition in \( S_0 \) becomes:

$$ \mathbf{n}_0^T \cdot \mathbf{B} \cdot \mathbf{r}_0 = 0 $$

By solving this equation simultaneously with the flexspline profile equations \( \mathbf{r}_0(s) \) for discrete values of the arc length parameter \( s \), one obtains the corresponding meshing angle \( \varphi(s) \) (or generator angle \( \beta(s) \)) at which that point becomes a contact point. Applying the full coordinate transformation \( \mathbf{r}_1 = \mathbf{M}_{10} \mathbf{r}_0 \) for each valid \( (s, \varphi(s)) \) pair yields the set of all theoretical conjugate contact points in the circular spline coordinate system \( S_1 \). This set of points is the theoretical conjugate flexspline profile as seen from the circular spline. A key phenomenon observed in this solution is “double conjugation,” where most points on the flexspline profile generate two separate conjugate loci on the circular spline side at different wave generator angles.

To design the actual circular spline tooth profile, the outermost envelope of these conjugate loci is selected to avoid tooth interference during operation. For a triple-arc flexspline, this typically involves segments from the first conjugate of the addendum arc (\(L^{1}_{AB}\)), the first conjugate of the middle arc (\(L^{1}_{BC}\)), and the second conjugate of the addendum arc (\(L^{2}_{AB}\)). This composite curve is then approximated by a new set of three circular arcs using fitting algorithms. The radii of these fitted arcs are then slightly adjusted (usually increased for convex sections and decreased for concave sections relative to the conjugate curve) to introduce a minimal, controlled working clearance, resulting in the final manufactured circular spline profile. The parameters for an example circular spline profile conjugate to a given triple-arc flexspline are shown below:

| Circular Spline Arc Segment | Center Coordinates (mm) | Fitted Radius (mm) |

|---|---|---|

| Dedendum Convex Arc | (-0.4294, 26.0108) | 0.5265 |

| Middle Arc | (-2.4321, 25.4117) | 2.6845 |

| Addendum Concave Arc | (0.7225, 25.8219) | 0.6402 |

4. Meshing Performance Analysis of the Triple-Arc Strain Wave Gear

With both tooth profiles defined, a detailed analysis of the meshing performance can be conducted. This analysis is critical for predicting the behavior and suitability of this strain wave gear design for practical applications.

4.1 Conjugate Profile Deviation

The deviation between the theoretical conjugate flexspline profile (the exact kinematic envelope) and the final designed circular spline profile (the adjusted arc fit) is a direct measure of the theoretical perfection of the meshing pair. It indicates how closely the manufactured circular spline will approximate ideal conjugate motion with the flexspline. For the example triple-arc design, the deviations for the primary conjugate segments \(L^{1}_{AB}\), \(L^{1}_{BC}\), \(L^{2}_{BC}\), and \(L^{1}_{CD}\) are extremely small. The deviation values typically fall within the range of \([-0.38, 0.23] \mu m\), with a mean absolute deviation on the order of \(0.08 \mu m\). This negligible deviation confirms that the circular spline profile, derived via arc-fitting from the conjugate loci, maintains excellent theoretical conjugacy with the flexspline motion. Furthermore, all theoretical conjugate points lie on or inside the final circular spline profile, guaranteeing the absence of profile interference under no-load conditions.

4.2 Contact Ratio (Overlap)

The contact ratio, or overlap, is a fundamental metric for gear performance, indicating the average number of tooth pairs in simultaneous contact. A high contact ratio contributes to smoother operation, lower noise, higher load-sharing capability, and increased torsional stiffness. In a double-wave strain wave gear, the theoretical contact ratio can be calculated based on the angular extent of the continuous meshing zone within one quadrant. If \( \phi_s \) represents the angular range of effective meshing in the circular spline coordinate system within one 90-degree quadrant, and \( Z_g \) is the number of teeth on the circular spline, the contact ratio \( \epsilon \) is given by:

$$ \epsilon = \frac{4 \phi_s}{360^\circ} \times Z_g $$

For the analyzed triple-arc strain wave gear example, the effective continuous conjugate zones from segments \(L^{1}_{AB}\) and \(L^{1}_{BC}\) might span, for instance, from \( \varphi = -0.0019^\circ \) to \( 9.5115^\circ \) and from \( 12.7566^\circ \) to \( 45.7013^\circ \). The significant zone \( \phi_s \) is taken as the combined effective range, e.g., approximately \( 41.88^\circ \). For a circular spline with \( Z_g = 162 \) teeth:

$$ \epsilon = \frac{4 \times 41.88^\circ}{360^\circ} \times 162 \approx 75.4 $$

This result implies that, under no-load conditions, approximately 75 pairs of teeth are theoretically in contact at any given time, representing about 46% of the total teeth on the circular spline. Under load, tooth bending and contact deformation will likely increase this effective contact ratio further. This exceptionally high contact ratio is a hallmark of strain wave gearing and is particularly well-supported by the wide meshing zone of the triple-arc design, leading to outstanding load capacity and smoothness.

4.3 Maximum Tooth Engagement Depth

The maximum engagement depth \( h_n \) is the radial distance a flexspline tooth penetrates into the circular spline space when fully engaged. A greater engagement depth generally correlates with higher torsional stiffness and torque capacity. It is calculated as the difference between the radial position of the initial meshing point on the flexspline \( r_{rs} \), the radial position of the final meshing point on the circular spline \( r_{ge} \), and the wave generator’s radial deformation \( \omega_0 \), but must satisfy geometric constraints to avoid pointed teeth or interference.

$$ h_n = r_{rs} + \omega_0 – r_{ge} $$

The value must be less than the available space below the flexspline addendum and greater than the module \( m \) for proper tooth strength:

$$ m \leq h_n \leq 0.5m(Z_r + 2x_r) + h_a – r_{rs} $$

where \( Z_r \) is the flexspline tooth count and \( x_r \) is its profile shift coefficient. For a typical design with \( m=0.32 \) mm, \( \omega_0 = 0.32 \) mm, and calculated \( r_{rs} \) and \( r_{ge} \), the engagement depth \( h_n \) can meet these conditions, confirming a robust design. This analysis underscores the ability of the triple-arc strain wave gear to achieve a favorable and deep mesh.

4.4 Transmission Backlash Analysis

Backlash, the clear space between mating tooth surfaces, is a critical design parameter for precision strain wave gears. While some backlash is necessary to prevent jamming and accommodate manufacturing errors and thermal expansion, excessive backlash compromises positioning accuracy and can induce vibration. The goal is a minimal, uniform distribution of backlash across the many simultaneously engaged tooth pairs. The backlash for any instantaneous meshing position is found by calculating the minimum distance between the discrete points of the flexspline tooth profile (positioned according to its wave generator phase) and the discrete points of the circular spline tooth profile.

For a flexspline profile point \( M_{ri}(X_{ri}, Y_{ri}) \) at a specific meshing phase \( \phi_i \), and a circular spline profile point \( M_{gj}(X_{gj}, Y_{gj}) \), their distance is:

$$ j_{M,ij} = \sqrt{ (X_{ri} – X_{gj})^2 + (Y_{ri} – Y_{gj})^2 } $$

The minimum value of \( j_{M,ij} \) over all circular spline points \( j \) is the instantaneous clearance for that flexspline point. The minimum among all clearances on a given tooth pair is that pair’s operational backlash. Analyzing all tooth pairs engaged on one side of the wave generator major axis reveals the backlash distribution.

For the example triple-arc strain wave gear, analysis might show 23 tooth pairs in simultaneous engagement on one flank. The backlash across these pairs is positive and generally uniform for the first 22 pairs, with values ranging from a minimum of about \( 2.24 \mu m \) to a maximum of about \( 6.38 \mu m \), and an average near \( 3.53 \mu m \). The last pair (the one about to disengage) typically shows a significantly larger backlash (e.g., \( 23.36 \mu m \)) to ensure clean disengagement without tip interference. This controlled and small backlash distribution, characteristic of well-designed strain wave gears, is achievable with the triple-arc profile and contributes directly to high transmission accuracy.

5. Conclusion

The triple-circular-arc tooth profile presents a refined and promising design direction for high-performance strain wave gears. Through the application of precise conjugate theory and numerical methods, a compatible circular spline profile can be successfully generated. The subsequent meshing performance analysis yields highly favorable results. The deviations between the theoretical conjugate flexspline profile and the manufactured circular spline profile are negligible, confirming near-perfect theoretical conjugacy and a non-interference condition. The strain wave gear utilizing this profile exhibits an exceptionally high contact ratio, which directly translates to superior load distribution, smooth motion transmission, and high torsional stiffness. Furthermore, the calculated maximum engagement depth indicates a robust tooth mesh capable of handling significant loads. Finally, the analysis reveals that the design achieves a minimal and uniformly distributed backlash across the vast majority of simultaneously engaged tooth pairs, which is paramount for achieving the high positioning accuracy for which strain wave gears are renowned. In summary, the triple-arc strain wave gear demonstrates excellent potential across key performance metrics—load capacity, stiffness, smoothness, and precision—making it a compelling subject for continued research and development aimed at pushing the boundaries of precision motion control technology.