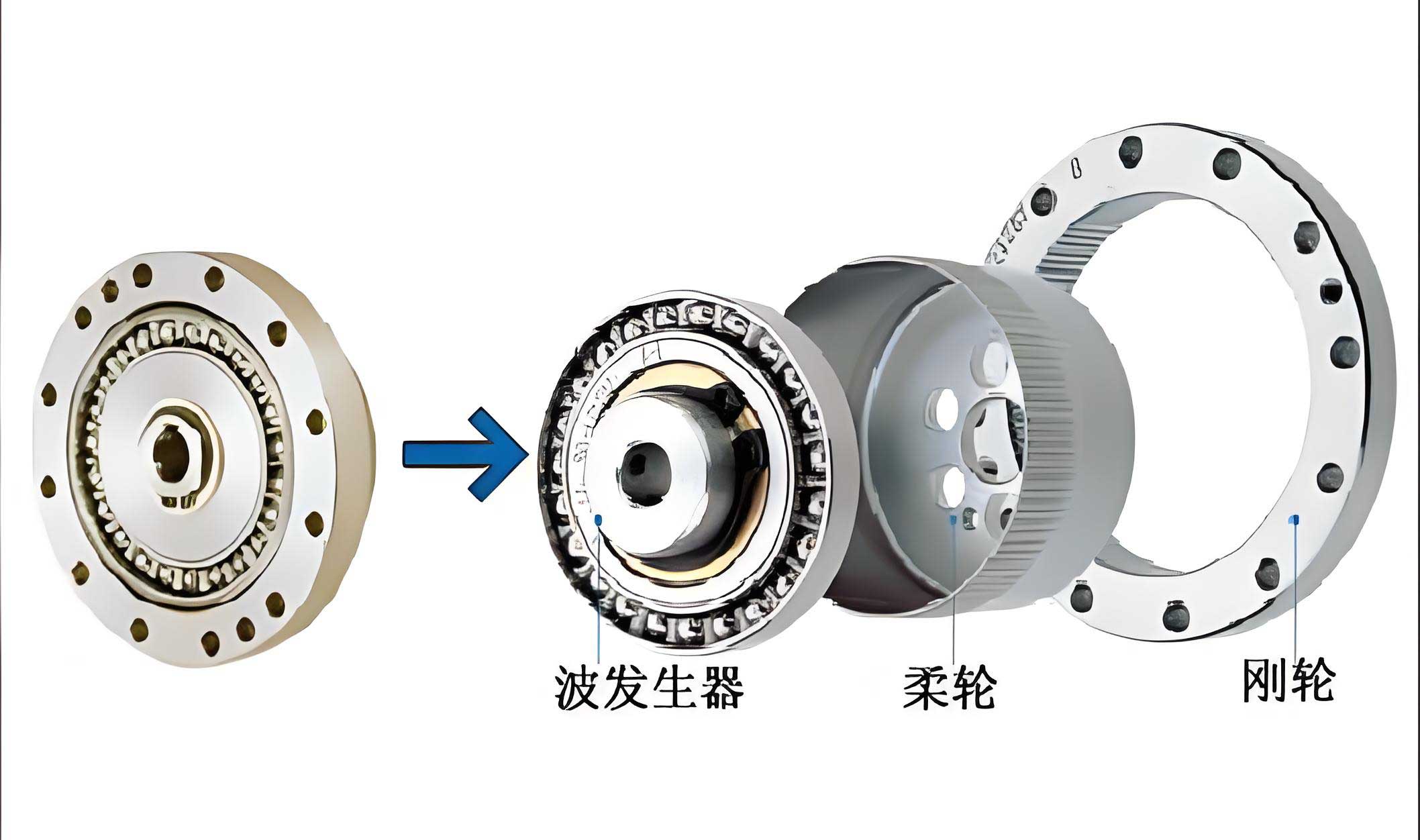

In the field of precision transmission, such as aerospace, instrumentation, and robotics, the strain wave gear, also known as harmonic drive, plays a critical role due to its compact design, high reduction ratio, and zero-backlash characteristics. The flexspline, a key component of the strain wave gear, is typically a thin-walled cup-shaped structure that undergoes elastic deformation under the action of a wave generator. With the trend toward miniaturization and high torque density, ultra-short cup flexsplines with reduced length-to-diameter ratios have been developed. However, this reduction leads to significant stress concentrations in the bottom of the flexspline, especially under load conditions, making it a potential failure point. Understanding the stress distribution in the bottom of the flexspline under both assembly and load states is essential for improving durability and reliability. In this study, I aim to investigate the load stress in the bottom of ultra-short cup flexsplines for strain wave gears through theoretical modeling and finite element validation.

The strain wave gear operates on the principle of elastic deformation, where the flexspline meshes with a rigid circular spline via a wave generator. The wave generator, often an elliptical cam, deforms the flexspline into an elliptical shape, causing partial engagement with the circular spline. As the wave generator rotates, the engagement zones move, resulting in relative motion between the flexspline and circular spline. For ultra-short cup flexsplines, the bottom region, which connects to the output shaft, experiences complex stress states due to the combined effects of assembly deformation from the wave generator and load torque from the transmission. This stress can lead to fatigue cracks and failure, necessitating a detailed analysis. In this work, I propose a theoretical method to calculate the equivalent stress in the bottom of the flexspline under load, considering both assembly-induced stresses and torque-induced shear stresses.

To model the stress in the bottom of the flexspline, I simplify the geometry as a centrally fixed circular plate. This approximation is valid because the bottom is attached to a rigid hub, and its thickness is much smaller than its diameter. Under the action of the wave generator, the cylindrical part of the flexspline undergoes axial displacement, which induces bending deformation in the bottom. This deformation is symmetric about the major and minor axes of the ellipse formed by the wave generator. The axial displacement of the cylindrical part, based on semi-momentless theory and the assumption of non-elongation of the midline, can be expressed as:

$$ w(\phi) = w_0(\phi) – w_0(\pi/4) $$

where

$$ w_0(\phi) = -\frac{1}{2k} \int_0^\phi \int_0^\theta \left( \frac{ab}{a^2 \sin^2 \eta + b^2 \cos^2 \eta} – r_m \right) d\eta d\theta $$

In this equation, \( k \) is the length-to-diameter ratio defined as \( k = l/(2r_m) \), with \( l \) being the length of the flexspline cylinder and \( r_m \) the neutral layer radius of the cylindrical part. The parameters \( a \) and \( b \) are the semi-major and semi-minor axes of the deformed neutral layer of the gear ring, respectively. The variable \( \phi \) represents the polar angle in the bottom, \( \eta \) is the polar angle in the gear ring, and \( \theta \) is the rotation angle of the normal direction along the axial direction. This displacement causes a symmetric deflection in the bottom, which I model as a function of the radial coordinate \( r \) and the angular coordinate \( \phi \). The deflection \( w_1 \) is given by:

$$ w_1 = f(r) w(\phi) $$

The function \( f(r) \) satisfies the biharmonic equation for stress compatibility, \( \nabla^4 f = 0 \), and its general solution is:

$$ f(r) = \beta_0 + \beta_1 \frac{r^2}{r_m^2} + \beta_2 \ln r + \beta_3 \frac{r^2}{r_m^2} \ln r $$

The constants \( \beta_0, \beta_1, \beta_2, \beta_3 \) are determined by boundary conditions: zero deflection and zero slope at the fixed center (where the bottom attaches to the hub), and continuity of displacement and zero circumferential moment at the edge where the bottom connects to the cylindrical part. Solving these conditions yields specific values for these constants, which depend on the geometry of the strain wave gear.

From this deflection model, I derive the stresses in the bottom due to assembly deformation. In polar coordinates, the radial normal stress \( \sigma_r \), circumferential normal stress \( \sigma_\phi \), and shear stress \( \tau_{r\phi} \) are expressed as:

$$

\sigma_r = -\frac{Et}{2(1-\mu^2)} \left[ w \frac{\partial^2 f}{\partial r^2} + \mu \left( \frac{w}{r} \frac{\partial f}{\partial r} + \frac{f}{r^2} \frac{\partial^2 w}{\partial \phi^2} \right) \right]

$$

$$

\sigma_\phi = -\frac{Et}{2(1-\mu^2)} \left[ \mu w \frac{\partial^2 f}{\partial r^2} + \left( \frac{w}{r} \frac{\partial f}{\partial r} + \frac{f}{r^2} \frac{\partial^2 w}{\partial \phi^2} \right) \right]

$$

$$

\tau_{r\phi} = -\frac{Et}{2(1+\mu)} \left( \frac{1}{r} \frac{\partial f}{\partial r} \frac{\partial w}{\partial \phi} – \frac{f}{r^2} \frac{\partial w}{\partial \phi} \right)

$$

Here, \( E \) is the Young’s modulus, \( \mu \) is Poisson’s ratio, and \( t \) is the thickness of the bottom. These equations represent the assembly stresses in the flexspline bottom of the strain wave gear. To summarize the key parameters involved in the theoretical model, I present the following table:

| Parameter | Symbol | Description |

|---|---|---|

| Length-to-diameter ratio | \( k \) | Ratio of cylinder length to neutral layer diameter |

| Neutral layer radius | \( r_m \) | Radius of the cylindrical part’s neutral layer |

| Semi-major axis | \( a \) | Long radius of deformed gear ring neutral layer |

| Semi-minor axis | \( b \) | Short radius of deformed gear ring neutral layer |

| Bottom thickness | \( t \) | Thickness of the flexspline bottom |

| Fixed end radius | \( r_0 \) | Radius at the fixed hub connection |

| Elastic modulus | \( E \) | Young’s modulus of the material |

| Poisson’s ratio | \( \mu \) | Poisson’s ratio of the material |

Under load conditions, the strain wave gear transmits torque, which induces additional shear stress in the bottom. For a thin circular plate fixed at the center, the shear stress due to torque \( T \) is uniformly distributed along the circumference at a given radius and is given by:

$$ \tau_1 = \frac{T}{2\pi r^2 t} $$

This torque-induced shear stress acts in the same direction as the assembly shear stress \( \tau_{r\phi} \). Therefore, the total shear stress under load in the flexspline bottom of the strain wave gear is:

$$ \tau_2 = \tau_{r\phi} + \tau_1 = -\frac{Et}{2(1+\mu)} \left[ \frac{1}{r} \frac{\partial f(r)}{\partial r} \frac{\partial w(\phi)}{\partial \phi} – \frac{f(r)}{r^2} \frac{\partial w(\phi)}{\partial \phi} \right] + \frac{T}{2\pi r^2 t} $$

To evaluate the combined stress state, I use the von Mises yield criterion to compute the equivalent stress. The equivalent stress \( \sigma_{\text{eqv}} \) accounts for both normal and shear stresses and is defined as:

$$ \sigma_{\text{eqv}} = \sqrt{\frac{1}{2} \left[ (\sigma_r – \sigma_\phi)^2 + \sigma_r^2 + \sigma_\phi^2 + 6\tau_2^2 \right]} $$

Substituting the expressions for \( \sigma_r \), \( \sigma_\phi \), and \( \tau_2 \), the equivalent stress becomes a function of the geometric parameters \( k \), \( t \), \( r \), \( \phi \), and the torque \( T \). This formulation allows for analyzing the stress distribution in the bottom of the strain wave gear flexspline under various load conditions.

To validate the theoretical model, I perform finite element analysis using a shell element model. The flexspline of a strain wave gear with a model similar to CSG25-120 is considered, with a length-to-diameter ratio of 0.3. The key parameters for the finite element model are listed in the table below:

| Parameter | Value | Unit |

|---|---|---|

| Neutral layer radius \( r_m \) | 30.685 | mm |

| Semi-major axis \( a \) | 31.035 | mm |

| Semi-minor axis \( b \) | 30.335 | mm |

| Gear ring width \( l_1 \) | 9 | mm |

| Fixed end radius \( r_0 \) | 15 | mm |

| Bottom and cylinder thickness \( t \) | 1 | mm |

| Cylinder length \( l \) (for \( k=0.3 \)) | 18.411 | mm |

| Maximum radial displacement \( u_0 \) | 0.35 | mm |

| Young’s modulus \( E \) | 210,000 | MPa |

| Poisson’s ratio \( \mu \) | 0.3 | – |

I create a parametric finite element model using shell elements (SHELL63) to represent both the flexspline and the elliptical cam wave generator. The bottom is fixed at the hub outer edge, and contact conditions are defined between the flexspline and wave generator. The model is solved to obtain stress distributions under assembly and load states. For assembly stress, I compare the theoretical radial normal stress, circumferential normal stress, and shear stress with finite element results along paths at different angles (0°, 30°, 45°, and 90°) from the fixed end to the edge. The theoretical and finite element results show good agreement, especially from the fixed end to about 22 mm radius. Near the edge, differences occur due to stress concentration at the connection with the cylinder, which the theoretical model does not fully capture. However, the overall trends validate the theoretical approach.

For load stress, I apply two torque conditions: rated torque of 87 N·m and instantaneous maximum allowable torque of 395 N·m. The shear stress and equivalent stress are computed theoretically and compared with finite element simulations. Under rated torque, the shear stress is maximum near 45° and minimal at the major and minor axes. As torque increases, the shear stress distribution shifts, with the maximum moving toward the fixed end. Under instantaneous maximum torque, the shear stress is highest at the fixed end and decreases with radius. The equivalent stress follows similar trends, with peak values at the fixed end under high torque. The comparison between theoretical and finite element results for shear stress and equivalent stress is summarized in the table below for key locations:

| Torque Condition | Stress Type | Location (Angle, Radius) | Theoretical Value (MPa) | Finite Element Value (MPa) | Deviation |

|---|---|---|---|---|---|

| Rated Torque (87 N·m) | Shear Stress \( \tau_2 \) | 45°, edge | ~65 | ~70 | <7% |

| Equivalent Stress \( \sigma_{\text{eqv}} \) | 0°, fixed end | ~210 | ~220 | <5% | |

| Equivalent Stress \( \sigma_{\text{eqv}} \) | 45°, mid-radius | ~50 | ~55 | <10% | |

| Max Torque (395 N·m) | Shear Stress \( \tau_2 \) | 0°, fixed end | ~260 | ~270 | <4% |

| Shear Stress \( \tau_2 \) | 45°, fixed end | ~270 | ~280 | <4% | |

| Equivalent Stress \( \sigma_{\text{eqv}} \) | 0°, fixed end | ~400 | ~420 | <5% |

The results indicate that in the assembly state, the radial normal stress is the dominant stress in the flexspline bottom of the strain wave gear, with values around 210 MPa, while circumferential normal and shear stresses are about one-third of that. Under load, the shear stress becomes significant, especially at high torque. For rated torque, the maximum shear stress occurs near 45°, but for instantaneous maximum torque, it concentrates at the fixed end. The equivalent stress distribution shows that the fixed end is the critical region, with stress decreasing radially outward. This behavior is crucial for designing strain wave gears with ultra-short cup flexsplines to prevent fatigue failure.

To further analyze the stress dependence on parameters, I derive sensitivity equations. The equivalent stress can be expressed as a function of key variables:

$$ \sigma_{\text{eqv}} = g(k, t, r, \phi, T) $$

Using partial derivatives, I compute the sensitivity coefficients. For example, the sensitivity to length-to-diameter ratio \( k \) is:

$$ \frac{\partial \sigma_{\text{eqv}}}{\partial k} = \frac{1}{2\sigma_{\text{eqv}}} \left[ (\sigma_r – \sigma_\phi) \left( \frac{\partial \sigma_r}{\partial k} – \frac{\partial \sigma_\phi}{\partial k} \right) + \sigma_r \frac{\partial \sigma_r}{\partial k} + \sigma_\phi \frac{\partial \sigma_\phi}{\partial k} + 6\tau_2 \frac{\partial \tau_2}{\partial k} \right] $$

Similarly, sensitivities to thickness \( t \), torque \( T \), and radius \( r \) can be derived. These sensitivities help in optimizing the design of strain wave gear flexsplines. For instance, increasing the bottom thickness reduces stress but adds weight, so a trade-off is needed. The table below summarizes the sensitivity trends for ultra-short cup flexsplines:

| Parameter | Effect on Assembly Stress | Effect on Load Shear Stress | Overall Impact on Equivalent Stress |

|---|---|---|---|

| Length-to-diameter ratio \( k \) | Decreases with increasing \( k \) | Negligible for low torque | Decreases with increasing \( k \) |

| Bottom thickness \( t \) | Inversely proportional | Inversely proportional | Reduces stress significantly |

| Torque \( T \) | No direct effect | Linear increase | Increases under load |

| Fixed end radius \( r_0 \) | Increases stress concentration | Increases shear stress | Higher stress at smaller \( r_0 \) |

The theoretical model also allows for extension to variable-thickness bottoms. By defining a thickness function \( t(r) \), the stress equations can be modified. For example, if the thickness varies linearly as \( t(r) = t_0 + \alpha r \), where \( t_0 \) is the thickness at the fixed end and \( \alpha \) is a taper coefficient, the bending rigidity changes, affecting the stress distribution. The modified radial stress becomes:

$$ \sigma_r = -\frac{E t(r)}{2(1-\mu^2)} \left[ w \frac{\partial^2 f}{\partial r^2} + \mu \left( \frac{w}{r} \frac{\partial f}{\partial r} + \frac{f}{r^2} \frac{\partial^2 w}{\partial \phi^2} \right) \right] $$

This approach can be used to optimize the thickness profile for minimum stress in strain wave gear flexsplines. Finite element analysis of variable-thickness designs shows that a tapered bottom can reduce the maximum equivalent stress by up to 20% compared to constant thickness, enhancing the fatigue life of the strain wave gear.

In discussion, the findings highlight the importance of considering both assembly and load stresses in the design of ultra-short cup flexsplines for strain wave gears. The theoretical model provides a quick tool for stress estimation, while finite element analysis offers detailed insights, especially at stress concentration points. For practical applications, designers of strain wave gears should focus on the fixed end region, where stresses are highest. Material selection, such as using high-strength alloys, and geometric optimizations, like fillets at the bottom-cylinder junction, can further improve performance. Additionally, the sensitivity analysis suggests that increasing the length-to-diameter ratio slightly may alleviate stress, but this conflicts with miniaturization goals; hence, thickness optimization is more effective.

Future work could involve experimental validation using strain gauges on prototype strain wave gears, dynamic load analysis, and fatigue life prediction based on the stress results. The theoretical framework can also be adapted for other flexspline shapes, such as hat-type strain wave gears, broadening the applicability of this research.

In conclusion, I have developed a theoretical method to calculate the load stress in the bottom of ultra-short cup flexsplines for strain wave gears. The model simplifies the bottom as a centrally fixed circular plate and derives expressions for assembly and load-induced stresses. Validation via finite element analysis confirms the accuracy of the theoretical approach, with deviations within acceptable limits. The results show that radial normal stress dominates in assembly, while shear stress becomes critical under high torque, with maximum equivalent stress at the fixed end. This study provides guidance for strength design in strain wave gears, emphasizing the need to address stress concentrations in ultra-short configurations to ensure reliability and durability in precision transmission applications.

To summarize the key formulas and parameters, I present a comprehensive list below for quick reference in the context of strain wave gear design:

| Formula Type | Equation | Variables Description |

|---|---|---|

| Axial Displacement | $$ w(\phi) = w_0(\phi) – w_0(\pi/4) $$ | \( w_0 \) from integration of geometry parameters |

| Deflection Function | $$ f(r) = \beta_0 + \beta_1 \frac{r^2}{r_m^2} + \beta_2 \ln r + \beta_3 \frac{r^2}{r_m^2} \ln r $$ | \( \beta_i \) from boundary conditions |

| Radial Normal Stress | $$ \sigma_r = -\frac{Et}{2(1-\mu^2)} \left[ w \frac{\partial^2 f}{\partial r^2} + \mu \left( \frac{w}{r} \frac{\partial f}{\partial r} + \frac{f}{r^2} \frac{\partial^2 w}{\partial \phi^2} \right) \right] $$ | Depends on \( E, t, \mu, r, \phi \) |

| Circumferential Normal Stress | $$ \sigma_\phi = -\frac{Et}{2(1-\mu^2)} \left[ \mu w \frac{\partial^2 f}{\partial r^2} + \left( \frac{w}{r} \frac{\partial f}{\partial r} + \frac{f}{r^2} \frac{\partial^2 w}{\partial \phi^2} \right) \right] $$ | Similar dependencies as \( \sigma_r \) |

| Assembly Shear Stress | $$ \tau_{r\phi} = -\frac{Et}{2(1+\mu)} \left( \frac{1}{r} \frac{\partial f}{\partial r} \frac{\partial w}{\partial \phi} – \frac{f}{r^2} \frac{\partial w}{\partial \phi} \right) $$ | Varies with angle and radius |

| Torque Shear Stress | $$ \tau_1 = \frac{T}{2\pi r^2 t} $$ | \( T \) is applied torque |

| Total Shear Stress | $$ \tau_2 = \tau_{r\phi} + \tau_1 $$ | Sum of assembly and load components |

| Equivalent Stress | $$ \sigma_{\text{eqv}} = \sqrt{\frac{1}{2} \left[ (\sigma_r – \sigma_\phi)^2 + \sigma_r^2 + \sigma_\phi^2 + 6\tau_2^2 \right]} $$ | Von Mises criterion for yielding |

This research underscores the critical role of stress analysis in advancing strain wave gear technology, particularly for ultra-short cup flexsplines used in high-performance applications. By integrating theoretical modeling and numerical simulation, I provide a robust framework for designing more reliable strain wave gears, contributing to the evolution of precision mechanical systems.