The demand for high-performance strain wave gear reducers is growing exponentially, particularly within the robotics industry, which mandates components with exceptional longevity, precision, and torque capacity. Traditional involute tooth profiles often fall short of these rigorous operational requirements due to their limited number of simultaneously engaged tooth pairs and constrained power transmission capability. In contrast, the double-circular-arc (DCA) tooth profile offers a superior solution, meeting the demands for high stiffness, long life, and high accuracy. However, the domestic industry’s grasp of the fundamental design principles for DCA profiles in strain wave gear remains largely elusive, with most manufacturers still reliant on involute profiles. This document details the development of a comprehensive theoretical model, the subsequent creation of Computer-Aided Design (CAD) software, and the verification via Finite Element Analysis (FEA) for the parametric design of DCA strain wave gears.

1. Introduction and Research Background

The strain wave gear reducer, a pivotal component in precision motion control, has evolved significantly since its inception. Modern applications, especially in robotics, impose stringent requirements that challenge traditional design paradigms. The core limitation of the widely used involute profile lies in its inherent geometry, which restricts the zone of simultaneous contact between the flexspline and the circular spline. This directly limits torque density, increases stress concentrations, and ultimately reduces the operational life and positioning accuracy of the strain wave gear assembly.

The DCA profile emerges as a technologically advanced response to these limitations. Its geometry is engineered to promote a larger, more distributed contact area between mating teeth during the wave generator’s rotation. This results in multiple tooth pairs sharing the load more effectively, leading to a substantial increase in torque capacity, stiffness, and service life for the strain wave gear. Despite its proven advantages, the complexity of accurately deriving the conjugate tooth profiles for both the flexspline and circular spline under elastic deformation has been a significant barrier. Many attempts have relied on empirical, trial-and-error methods, which are costly, time-consuming, and lack a robust theoretical foundation. This work aims to bridge that gap by establishing a precise mathematical model, automating the design process, and providing rigorous numerical validation.

2. Fundamental Principles of DCA Strain Wave Gear Design

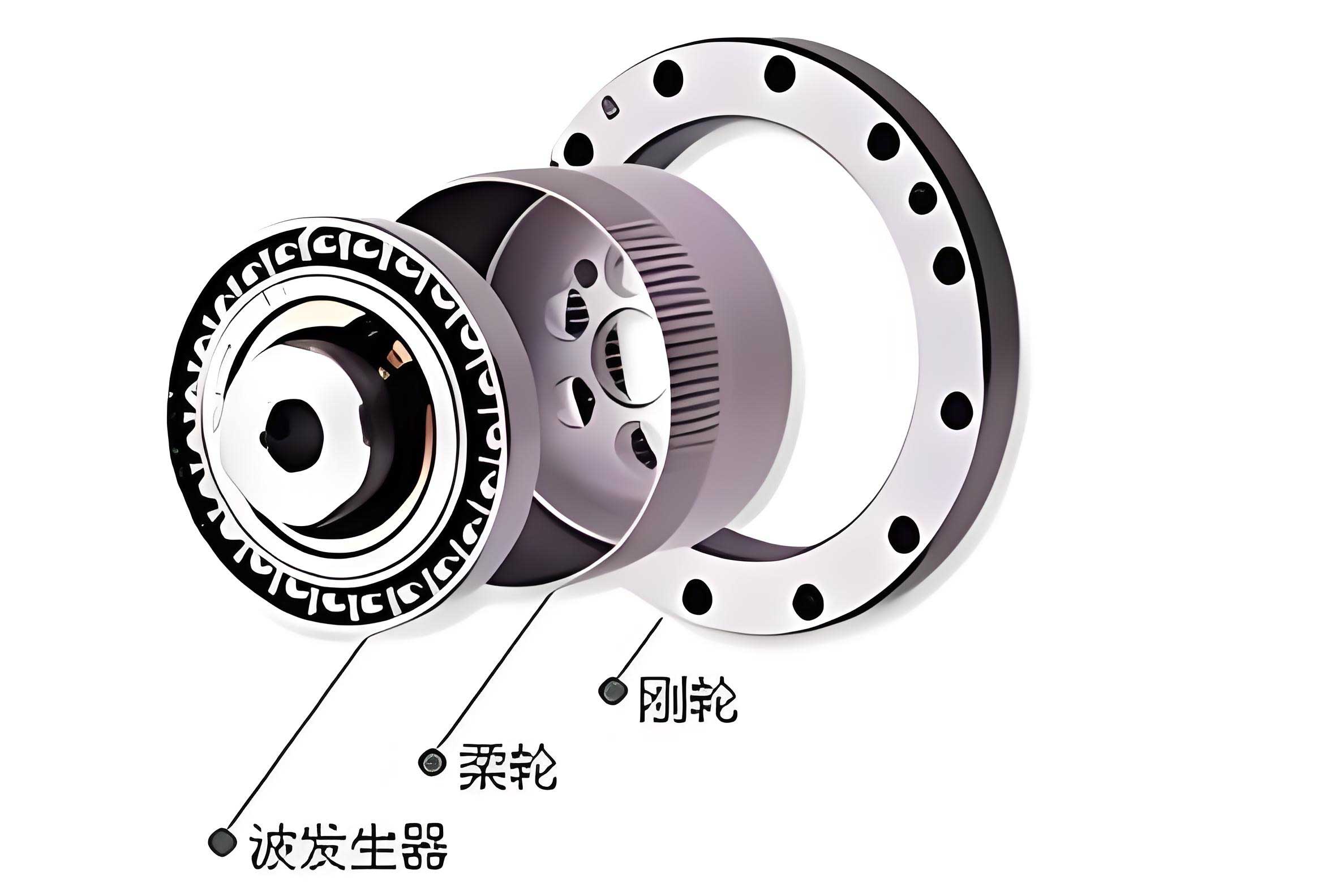

The operation of a strain wave gear relies on the controlled elastic deformation of a thin-walled flexspline by a wave generator, typically an elliptical cam paired with a flexible bearing. This deformation creates two opposing regions of meshing between the external teeth of the flexspline and the internal teeth of the rigid circular spline. The primary challenge in designing a high-performance strain wave gear is to define the tooth profiles such that they maintain precise, conjugate motion under this dynamic deformation state, minimizing interference and maximizing contact.

2.1 Model Assumptions and Parameters

To formulate a tractable yet accurate mathematical model, the following simplifying assumptions are made initially:

- The flexspline is modeled as a thin, cylindrical shell.

- Radial deformations are considered small.

- The neutral curve of the flexspline does not undergo circumferential elongation (this can be refined later).

- The tooth profile is treated as rigid relative to the flexspline body; deformation occurs only in the tooth space.

- The kinematic transmission ratio is constant, neglecting instantaneous fluctuations.

- The wave generator is a perfect, rigid elliptical contour.

The key geometric parameters for the DCA profile are defined in the following table:

| Symbol | Description |

|---|---|

| $m$ | Module |

| $Z_f$, $Z_c$ | Number of teeth on flexspline and circular spline |

| $\rho_a$, $\rho_f$, $\rho_c$ | Radius of addendum arc, root fillet arc, and bottom arc |

| $R_{af}$, $R_{ff}$ | Flexspline addendum and root circle radii |

| $r_f$ | Flexspline pitch circle radius ($r_f = m Z_f / 2$) |

| $r_m$ | Radius of the neutral curve |

| $e_a$, $e_f$ | Distance of arc centers from the pitch circle |

| $h_{af}$, $h_{ff}$ | Addendum and dedendum of the flexspline |

| $x^*_f$ | Profile shift coefficient for the flexspline |

| $\theta_1$, $\theta_2$ | Start and end angles for the addendum arc |

| $\theta_3$, $\theta_4$ | Start and end angles for the root fillet arc |

| $u(\theta)$, $v(\theta)$ | Radial and tangential displacement of the neutral curve |

| $\gamma(\theta)$ | Rotational displacement of a tooth section |

2.2 Undeformed Flexspline Tooth Profile

The flexspline is manufactured in its undeformed, circular state. Its tooth profile is composed of two circular arcs connected by a straight-line tangent segment, with supplemental tip and root relief arcs. In the local tooth coordinate system $X_2O_2Y_2$, the profile segments are defined as follows:

Addendum Arc:

$$ x_{c1}(\theta_x) = x_a + \rho_a \cos(\theta_x), \quad y_{c1}(\theta_x) = y_a + \rho_a \sin(\theta_x), \quad \theta_1 \leq \theta_x \leq \theta_2 $$

Root Fillet Arc:

$$ x_{c2}(\theta_x) = x_f – \rho_f \sin(\theta_x), \quad y_{c2}(\theta_x) = y_f – \rho_f \cos(\theta_x), \quad \theta_3 \leq \theta_x \leq \theta_4 $$

Tangent Segment:

$$ x_t(t) = x_{t0} + t \sin(\theta_1), \quad y_t(t) = y_{t0} – t \cos(\theta_1), \quad 0 \leq t \leq t_{max} $$

The coordinates $(x_a, y_a)$, $(x_f, y_f)$, the arc centers, and the limit angles are determined by a set of geometric continuity ($C^1$) conditions and design parameters like $e_a$, $e_f$, $\rho_a$, $\rho_f$, and the pressure angle. This ensures a smooth, continuous profile from the root to the tip of the strain wave gear flexspline tooth.

2.3 Deformed State of the Flexspline

When the wave generator is inserted, the flexspline’s neutral curve deforms from a perfect circle. A point $P$ on the neutral curve, originally at an angle $\theta$ from the major axis, undergoes radial displacement $u(\theta)$, tangential displacement $v(\theta)$, and its associated tooth section rotates by an angle $\gamma(\theta)$. The transformation from the local tooth coordinates $(x(\theta_x), y(\theta_x))$ to the global fixed coordinate system $X_1O_1Y_1$ involves a sequence of transformations:

1. Position before deformation (tooth located at $\theta$):

$$ X_{t1} = r_m \sin\theta + x(\theta_x)\cos\theta + (y(\theta_x)-r_m)\sin\theta $$

$$ Y_{t1} = r_m \cos\theta – x(\theta_x)\sin\theta + (y(\theta_x)-r_m)\cos\theta $$

2. New position of the neutral point $P$ after deformation:

$$ X_{t2} = (r_m + u(\theta))\sin\theta + v(\theta)\cos\theta $$

$$ Y_{t2} = (r_m + u(\theta))\cos\theta – v(\theta)\sin\theta $$

3. Final position of the tooth profile point after applying section rotation $\gamma$:

$$ X_2 = X_{t2} + (X_{t1} – r_m \sin\theta)\cos\gamma + (Y_{t1} – r_m \cos\theta)\sin\gamma $$

$$ Y_2 = Y_{t2} – (X_{t1} – r_m \sin\theta)\sin\gamma + (Y_{t1} – r_m \cos\theta)\cos\gamma $$

For a simple cylindrical flexspline under an elliptical cam, the deformation functions can be approximated as $u(\theta) = w_0 \cos(2\theta)$, $v(\theta) = – (w_0/2) \sin(2\theta)$, and $\gamma(\theta) = – (w_0 / r_m) \sin(2\theta)$, where $w_0$ is the radial deformation at the major axis.

2.4 Envelope Theory for Circular Spline Generation

The circular spline tooth profile is the envelope of the family of curves traced by the deformed flexspline teeth as the wave generator rotates. Let the wave generator rotation angle be $\phi_1$. For a fixed circular spline, the flexspline rotates by $\phi_2 = -\phi_1 / i$, where $i = Z_f / 2$ for a standard two-wave strain wave gear.

The family of flexspline tooth profiles in the fixed coordinate system is given by rotating the deformed profile $[X_2, Y_2]^T$ by the flexspline’s rotation $\phi_2$:

$$ \begin{bmatrix} X_T(\theta_x, \phi_1) \\ Y_T(\theta_x, \phi_1) \end{bmatrix} = \begin{bmatrix} \cos\phi_2 & -\sin\phi_2 \\ \sin\phi_2 & \cos\phi_2 \end{bmatrix} \begin{bmatrix} X_2(\theta_x, \phi_1) \\ Y_2(\theta_x, \phi_1) \end{bmatrix} $$

The envelope condition, ensuring a common tangent between consecutive positions, is:

$$ \frac{\partial X_T}{\partial \theta_x} \frac{\partial Y_T}{\partial \phi_1} – \frac{\partial X_T}{\partial \phi_1} \frac{\partial Y_T}{\partial \theta_x} = 0 $$

Solving the system comprising the profile equations and the envelope condition for $\theta_x$ and $\phi_1$ yields the coordinates of the circular spline tooth profile $[X_C(\phi_1), Y_C(\phi_1)]^T$. This process is the core of the theoretical model for the strain wave gear.

3. Development of Computer-Aided Design Software

To translate the complex theoretical model into a practical engineering tool, a dedicated CAD software was developed. This software automates the entire calculation and visualization pipeline for the strain wave gear design.

| Software Module | Core Function | Output |

|---|---|---|

| Core Solver | Implements the mathematical model: solves geometric constraints for the DCA profile, calculates deformed state, and performs envelope generation. | Coordinates for flexspline and circular spline tooth profiles. |

| Cutter Generation | Applies envelope theory a second time: uses the circular spline profile to generate its conjugate gear (shaper cutter), and uses the flexspline profile to generate the hob cutter profile. | Optimized circular arc parameters for the shaper and hob cutters, ensuring manufacturability. |

| Visualization & M-Value | Graphically displays the meshing of profiles. Calculates the over-pin measurement (M-value) for quality control of the manufactured strain wave gear components. | Graphical plots and quality control data sheets. |

| GUI (VC++ based) | Provides an intuitive Windows interface for inputting design parameters (module, tooth numbers, deformation, etc.) and executing all calculations. | A standalone, user-friendly application for strain wave gear design. |

The software significantly reduces development time and cost by eliminating physical trial-and-error loops. It allows for rapid iteration and optimization of the strain wave gear tooth geometry before any metal is cut.

4. Finite Element Analysis and Profile Correction

The initial theoretical model assumes a simple cylindrical flexspline. In reality, a practical strain wave gear flexspline has a complex geometry with a diaphragm or other end-connection for torque output. This added structure imposes additional boundary constraints that alter the deformation field from the idealized elliptical form, potentially causing meshing interference and reducing the strain wave gear’s performance.

4.1 FEA Model for Complex Flexspline

A high-fidelity Finite Element model is constructed using the profiles generated by the CAD software. The model typically includes a 90-degree sector to leverage symmetry, applying appropriate boundary conditions. Contact elements are defined between the wave generator (modeled as a rigid elliptical surface) and the flexspline bore, as well as between the flexspline teeth and the circular spline teeth. The analysis solves for the deformed state under a no-load assembly condition.

4.2 Extraction and Modeling of the Neutral Curve

The key output from the FEA is the actual displacement field of the complex flexspline. Nodal displacements along the theoretical neutral layer are extracted. These discrete data points $(x_k, y_k)$, representing the deformed neutral curve, are then fitted with a smooth, high-accuracy cubic spline function $S(x)$. This ensures $C^2$ continuity (continuous second derivative), which is crucial for accurate kinematic analysis of the strain wave gear.

For a cubic spline over intervals $[x_k, x_{k+1}]$, the function is:

$$ S_k(x) = M_k \frac{(x_{k+1}-x)^3}{6h_k} + M_{k+1} \frac{(x-x_k)^3}{6h_k} + \left(y_k – \frac{M_k h_k^2}{6}\right)\frac{x_{k+1}-x}{h_k} + \left(y_{k+1} – \frac{M_{k+1} h_k^2}{6}\right)\frac{x-x_k}{h_k} $$

where $h_k = x_{k+1} – x_k$. The second derivative moments $M_k$ are solved from the tridiagonal system ensuring continuity and specified end conditions:

$$ \mu_k M_{k-1} + 2M_k + \lambda_k M_{k+1} = d_k, \quad k=2,…,n-1 $$

with $\mu_k = h_{k-1}/(h_{k-1}+h_k)$, $\lambda_k = 1-\mu_k$, and $d_k = \frac{6}{h_{k-1}+h_k}\left(\frac{y_{k+1}-y_k}{h_k} – \frac{y_k-y_{k-1}}{h_{k-1}}\right)$.

The resulting spline functions $S(x)$ for the $X$ and $Y$ displacements provide highly accurate analytical expressions for $u(\theta)$ and $v(\theta)$ of the complex flexspline.

4.3 Profile Correction and Final Validation

The refined displacement functions $u(\theta)$ and $v(\theta)$ from the FEA/spline model are fed back into the core mathematical model (Section 2.3 and 2.4). The software then recalculates the envelope to generate a new, corrected circular spline tooth profile. This corrected profile is specifically conjugate to the deformed state of the complex flexspline, not just the idealized simple cylinder.

A final FEA simulation, using the corrected profiles, demonstrates near-perfect meshing with minimal interference across the entire engagement zone of the strain wave gear. This closed-loop process—theoretical design, FEA validation, neutral curve extraction, and profile correction—ensures the mathematical model’s accuracy is maintained for real-world geometries, guaranteeing high performance, low noise, and extended life for the strain wave gear reducer.

5. Conclusion

This work establishes a complete and verified methodology for the parametric design of double-circular-arc tooth profiles for strain wave gear reducers. The development of a rigorous theoretical model based on gear meshing and envelope theory forms the foundational core. The implementation of this model into specialized CAD software transforms the complex design process into an efficient, automated, and cost-effective engineering task, enabling rapid prototyping and optimization of strain wave gear designs.

Most importantly, the integration of high-fidelity Finite Element Analysis addresses the critical gap between idealized theory and practical complex flexspline geometry. By extracting the true deformation behavior via FEA and incorporating it back into the design loop through cubic spline modeling and profile correction, the methodology ensures that the final manufactured profiles will achieve precise, low-interference meshing. This process validates the underlying theoretical calculations and provides a powerful tool for developing high-performance, long-life, and high-torque-density strain wave gear reducers suitable for the most demanding applications like precision robotics.