In the field of precision mechanical transmission, the planetary roller screw assembly stands out as a critical component for converting rotary motion into linear motion. Compared to ball screws, the planetary roller screw assembly offers higher theoretical load capacity, longer service life, and improved reliability. However, in practical applications, especially in domestically produced systems, the actual performance often falls short of theoretical expectations. A key reason for this discrepancy lies in the presence of errors introduced during manufacturing and assembly processes. These errors can lead to uneven contact among the threads of the planetary roller screw assembly, with some threads potentially not making contact at all, severely compromising load distribution and lifespan. Therefore, investigating the meshing characteristics under error conditions is paramount for enhancing the performance of the planetary roller screw assembly. In this work, I develop a comprehensive meshing model that incorporates various error sources, providing a foundation for subsequent kinematic and dynamic analysis of the planetary roller screw assembly.

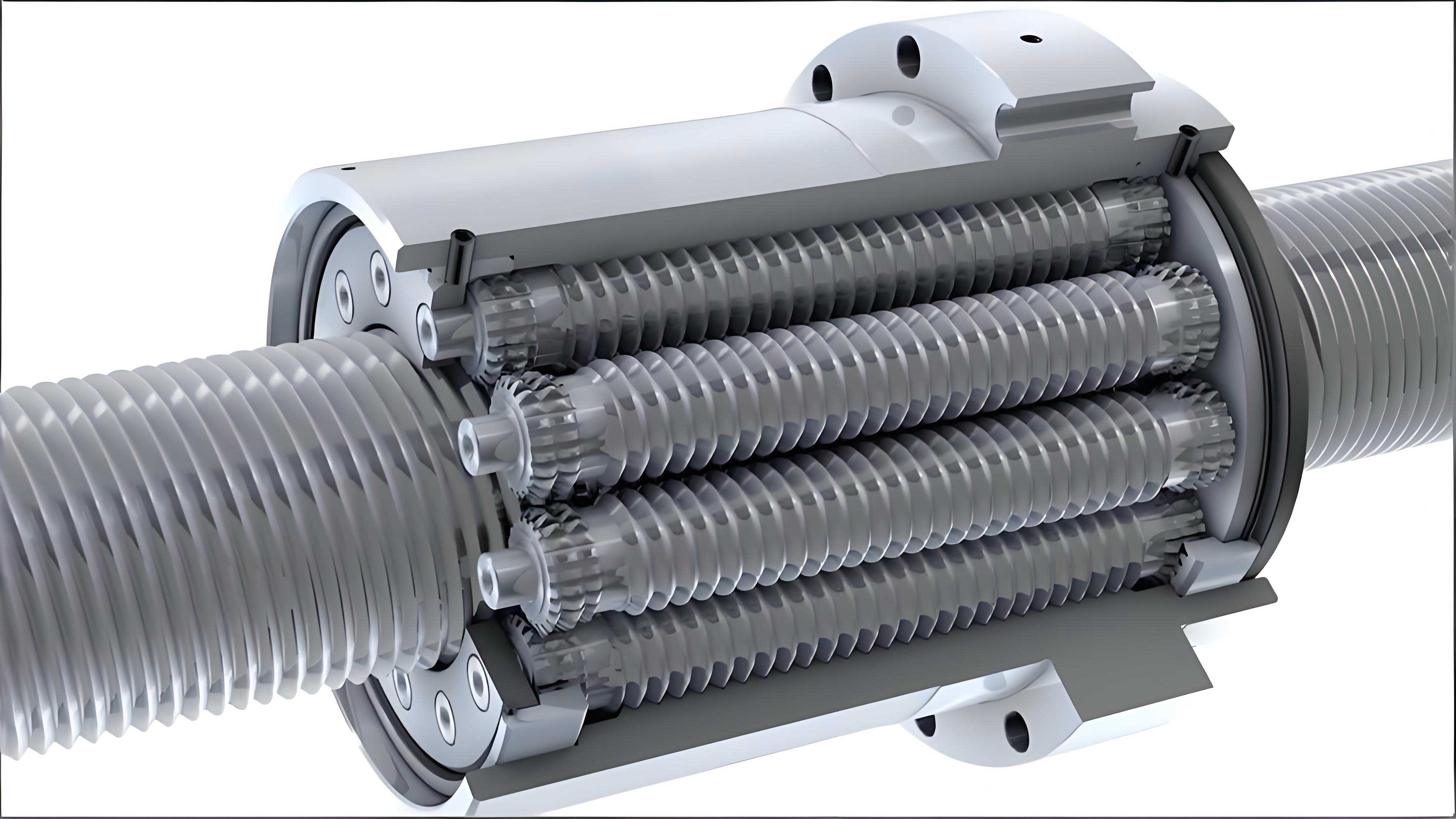

The planetary roller screw assembly consists of a screw, multiple circumferentially arranged rollers, a nut, and a retainer or cage. Its operation parallels that of a planetary gear system. When errors are present, the alignment and positioning of these components deviate from ideal conditions, altering contact points and characteristics. This study begins by analyzing the forms and quantitative manifestations of errors in the planetary roller screw assembly, followed by the derivation of spiral surface equations using rigid-body Euler theorems and coordinate transformations. A meshing model that accounts for errors is then proposed, solved numerically, and validated against other models and three-dimensional simulations. The results demonstrate the feasibility of this approach for studying deflected models of the planetary roller screw assembly.

Error Sources in Planetary Roller Screw Assembly

Errors in a planetary roller screw assembly primarily arise from two categories: thread parameter errors and roller positioning errors. These errors are inevitable due to manufacturing tolerances and assembly inaccuracies, and they significantly influence the meshing behavior of the planetary roller screw assembly.

Thread Parameter Errors

Thread parameter errors are associated with the machining of helical threads on the screw, rollers, and nut. They can be classified into three main types, as summarized in Table 1.

| Error Type | Symbol | Description | Effect on Planetary Roller Screw Assembly |

|---|---|---|---|

| Pitch Diameter Error | $\Delta d_i$ where $i=s, r, n$ | Deviation from the nominal pitch diameter for screw (s), roller (r), and nut (n). | Alters the nominal center distances, affecting thread engagement depth and clearance. |

| Helix Division Error | $\Delta \phi_i$ | Phase angle error between multiple thread starts due to indexing inaccuracies during machining. | Causes non-uniform load distribution among thread starts, leading to premature wear. |

| Thread Profile Error | $\Delta \beta_i$, $\Delta c_i$, $\Delta r$ | Includes thread flank angle error ($\Delta \beta_i$), half-tooth thickness error ($\Delta c_i$), and roller thread root radius error ($\Delta r$). | Changes the local geometry of contacting surfaces, influencing stress concentration and contact patterns. |

Mathematically, the pitch diameter error directly modifies the nominal diameter in spiral surface equations. The helix division error is incorporated as an additional rotation in the transformation matrix for multi-start threads. For a thread with $n$ starts and a division error $\Delta \phi_{ij}$ for the $j$-th start, the modified rotation matrix becomes:

$$ \mathbf{R}_{w_i} = \begin{bmatrix} \cos\left(\frac{2\pi j}{n} + \Delta \phi_{ij}\right) & -\sin\left(\frac{2\pi j}{n} + \Delta \phi_{ij}\right) & 0 & 0 \\ \sin\left(\frac{2\pi j}{n} + \Delta \phi_{ij}\right) & \cos\left(\frac{2\pi j}{n} + \Delta \phi_{ij}\right) & 0 & 0 \\ 0 & 0 & 1 & 0 \\ 0 & 0 & 0 & 1 \end{bmatrix} $$

Thread profile errors affect the parametric equations of the thread contour. For a standard trapezoidal thread, the ideal profile in a local coordinate system is given by $x’ = t$, $y’=0$, $z’ = \pm [t \tan(\beta) + c]$, where $\beta$ is the half flank angle and $c$ is the half-tooth thickness. With errors, this becomes:

$$ x’ = t, \quad y’ = 0, \quad z’ = \pm \left[ t \tan(\beta + \Delta \beta_i) + (c + \Delta c_i) \right] $$

For roller threads with a root radius $r$, the profile includes a circular arc, and the error $\Delta r$ modifies the radius value in the contour equations. These modifications are crucial for accurately modeling the planetary roller screw assembly.

Roller Positioning Errors

Roller positioning errors occur during the assembly of the planetary roller screw assembly. They are related to the retainer (cage) and its interaction with the rollers. Key errors include:

- Pin Hole Position Error: Deviation in the location of pin holes on the retainer that guide the rollers, leading to radial misalignment.

- Retainer Positioning Plane Error: Inaccuracies in the axial positioning plane of the retainer, causing axial displacement of rollers.

- Retainer Installation Torsion Error: Twisting of the retainer during installation, resulting in roller tilt or skew.

These errors collectively cause each roller to deviate from its ideal position and orientation. The deviation can be decomposed into rotational and translational components. In a fixed coordinate system $O-xyz$, where the $z$-axis aligns with the screw axis, the ideal roller coordinate system $O_{R’}-x_{R’}y_{R’}z_{R’}$ is offset by $(d_s + d_r)/2$ along the $x$-axis. Due to errors, the actual roller coordinate system $O_R-x_Ry_Rz_R$ is obtained by applying a rotation matrix $\mathbf{R}_{R’}^{R}$ and a translation vector $\mathbf{n} = [x, y, z]^T$ to the ideal system. The rotation is defined by Euler angles $\alpha$, $\beta$, $\gamma$ about the $x_{R’}$, $y_{R’}$, $z_{R’}$ axes, respectively. The transformation is:

$$ \begin{bmatrix} \mathbf{p}_{R’} \\ 1 \end{bmatrix} = \begin{bmatrix} \mathbf{R}_{R’}^{R} & \mathbf{n} \\ \mathbf{0} & 1 \end{bmatrix} \begin{bmatrix} \mathbf{p}_{R} \\ 1 \end{bmatrix} $$

where $\mathbf{p}_{R}$ is a point in the actual roller coordinates, $\mathbf{p}_{R’}$ is in the ideal coordinates, and the rotation matrix is:

$$ \mathbf{R}_{R’}^{R} = \begin{bmatrix} \cos\gamma & -\sin\gamma & 0 \\ \sin\gamma & \cos\gamma & 0 \\ 0 & 0 & 1 \end{bmatrix} \begin{bmatrix} \cos\beta & 0 & \sin\beta \\ 0 & 1 & 0 \\ -\sin\beta & 0 & \cos\beta \end{bmatrix} \begin{bmatrix} 1 & 0 & 0 \\ 0 & \cos\alpha & -\sin\alpha \\ 0 & \sin\alpha & \cos\alpha \end{bmatrix} $$

This comprehensive error representation allows us to model the actual state of each roller in the planetary roller screw assembly.

Development of the Meshing Model Considering Errors

To analyze the contact in a planetary roller screw assembly with errors, I first derive the mathematical equations for the spiral surfaces of all threads, incorporating the error parameters. Then, I establish the meshing conditions based on gear theory.

Spiral Surface Equations with Errors

The spiral surface of a thread is generated by a profile curve undergoing a screw motion. For external threads (screw and roller), I define a local profile coordinate system $O’-x’y’z’$ attached to a point on the pitch cylinder. The profile curve, considering errors, is represented parametrically. For the screw thread profile:

$$ x’ = t, \quad y’ = 0, \quad z’ = \pm \left[ -t \tan(\beta_s + \Delta \beta_s) + (c_s + \Delta c_s) \right] $$

where the $\pm$ sign denotes the upper (right) and lower (left) flanks. This profile is then transformed to the main screw coordinate system $O_s-x_s y_s z_s$, which coincides with the fixed system $O-xyz$. The transformation involves a translation to the pitch point and a rotation by the helical phase angle $\varphi$. The resulting screw spiral surface equation in fixed coordinates is:

$$ \begin{bmatrix} \mathbf{\Pi}_s \\ 1 \end{bmatrix} = \begin{bmatrix} \cos\varphi & -\sin\varphi & 0 & \frac{(d_s + \Delta d_s) \cos\varphi}{2} \\ \sin\varphi & \cos\varphi & 0 & \frac{(d_s + \Delta d_s) \sin\varphi}{2} \\ 0 & 0 & 1 & \frac{L_s \varphi}{2\pi} \\ 0 & 0 & 0 & 1 \end{bmatrix} \begin{bmatrix} t \\ 0 \\ \pm \left[ -t \tan(\beta_s + \Delta \beta_s) + (c_s + \Delta c_s) \right] \\ 1 \end{bmatrix} $$

Expanded, this gives:

$$ x_s = t \cos\varphi + \frac{(d_s + \Delta d_s) \cos\varphi}{2} $$

$$ y_s = t \sin\varphi + \frac{(d_s + \Delta d_s) \sin\varphi}{2} $$

$$ z_s = \pm \left[ -t \tan(\beta_s + \Delta \beta_s) + (c_s + \Delta c_s) \right] + \frac{L_s \varphi}{2\pi} $$

where $L_s$ is the lead of the screw. For multi-start screws, this equation is further multiplied by the division error matrix $\mathbf{R}_{w_s}$ from the left.

For the roller external thread, the process is similar but the main roller coordinate system $O_R-x_R y_R z_R$ is not aligned with the fixed system due to positioning errors. The transformation from roller coordinates to fixed coordinates involves the error-induced rotation $\mathbf{R}_{R’}^{R}$ and translation $\mathbf{n}$, as well as the initial offset. The profile curve for the roller thread includes a root radius $r_R$ (with error $\Delta r_R$) and is more complex. In roller coordinates, the profile can be expressed using a parameter $m$ for the lateral distance and an angle parameter for the arc. After incorporating errors, the profile equations become:

$$ x’_r = m \cos\Psi + \frac{(d_r + \Delta d_r) \cos\Psi}{2} $$

$$ y’_r = m \sin\Psi + \frac{(d_r + \Delta d_r) \sin\Psi}{2} $$

$$ z’_r = \pm \left[ (c_r + \Delta c_r) – \frac{\sqrt{2}}{2}(r_R + \Delta r_R) + \sqrt{ (r_R + \Delta r_R)^2 – \left( m + \frac{\sqrt{2}}{2} r_R + \frac{\sqrt{2}}{2} \Delta r_R \right)^2 } \right] + \frac{L_r \Psi}{2\pi} $$

where $\Psi$ is the helical phase angle for the roller. Transforming to fixed coordinates via the error transformation yields the roller spiral surface equation $\mathbf{\Pi}_r$ in $O-xyz$:

$$ \begin{bmatrix} \mathbf{\Pi}_r \\ 1 \end{bmatrix} = \begin{bmatrix} \mathbf{I} & \begin{bmatrix} \frac{d_s + \Delta d_s + d_r + \Delta d_r}{2} \\ 0 \\ 0 \end{bmatrix} \\ \mathbf{0} & 1 \end{bmatrix} \begin{bmatrix} \mathbf{R}_{R’}^{R} & \mathbf{n} \\ \mathbf{0} & 1 \end{bmatrix} \begin{bmatrix} \mathbf{\Pi}’_r \\ 1 \end{bmatrix} $$

where $\mathbf{\Pi}’_r$ is the surface in roller coordinates. The full expanded form is lengthy but systematically derived. For the nut internal thread, the approach is analogous, but the profile orientation is inverted. In nut coordinates $O_N-x_N y_N z_N$, which is offset by $p/2$ along the $z$-axis (where $p$ is the pitch), the profile equation with errors is:

$$ x’_n = l \cos\theta + \frac{(d_n + \Delta d_n) \cos\theta}{2} $$

$$ y’_n = l \sin\theta + \frac{(d_n + \Delta d_n) \sin\theta}{2} $$

$$ z’_n = \pm \left[ l \tan(\beta_n + \Delta \beta_n) + (c_n + \Delta c_n) \right] + \frac{L_n \theta}{2\pi} $$

Transforming to fixed coordinates gives the nut spiral surface $\mathbf{\Pi}_n$:

$$ x_n = l \cos\theta + \frac{(d_n + \Delta d_n) \cos\theta}{2} $$

$$ y_n = l \sin\theta + \frac{(d_n + \Delta d_n) \sin\theta}{2} $$

$$ z_n = \pm \left[ l \tan(\beta_n + \Delta \beta_n) + (c_n + \Delta c_n) \right] + \frac{L_n \theta}{2\pi} + \frac{p}{2} $$

For multi-start nuts, the division error matrix $\mathbf{R}_{w_n}$ is applied. These equations collectively describe the geometry of all contacting surfaces in the planetary roller screw assembly, inclusive of errors.

Meshing Condition Formulation

In a planetary roller screw assembly, contact between threads is theoretically line contact. However, for assembly ease and smooth operation, a small axial clearance is typically present. Let $\mathbf{\Gamma}_d$ and $\mathbf{\Gamma}_u$ represent the spiral surfaces of two mating threads (e.g., screw and roller, or roller and nut). At the point of contact, the surfaces must satisfy two conditions: positional continuity with clearance and parallelism of normals. Denoting an axial clearance vector $\mathbf{k} = (0, 0, \delta)$, where $\delta$ is the clearance value (positive for gap, negative for interference), the meshing conditions are:

$$ \mathbf{\Gamma}_d(u_1, v_1) + \mathbf{k} = \mathbf{\Gamma}_u(u_2, v_2) $$

$$ \mathbf{n}_d = \xi \mathbf{n}_u $$

where $\mathbf{n}_d$ and $\mathbf{n}_u$ are the unit normal vectors at the contact points on each surface, $\xi$ is a scalar constant, and $(u_1, v_1)$, $(u_2, v_2)$ are the surface parameters. The normal vector for a parametric surface $\mathbf{\Gamma}(u,v)$ is given by $\mathbf{n} = \frac{\partial \mathbf{\Gamma}}{\partial u} \times \frac{\partial \mathbf{\Gamma}}{\partial v}$ normalized.

For the planetary roller screw assembly, considering the screw-roller pair, the equations become:

$$ [\mathbf{\Gamma}_s]_{x} = [\mathbf{\Gamma}_r]_{x} $$

$$ [\mathbf{\Gamma}_s]_{y} = [\mathbf{\Gamma}_r]_{y} $$

$$ [\mathbf{\Gamma}_s]_{z} = [\mathbf{\Gamma}_r]_{z} + \delta_{sr} $$

$$ \mathbf{n}_s = \xi_{sr} \mathbf{n}_r $$

Similarly, for the roller-nut pair:

$$ [\mathbf{\Gamma}_r]_{x} = [\mathbf{\Gamma}_n]_{x} $$

$$ [\mathbf{\Gamma}_r]_{y} = [\mathbf{\Gamma}_n]_{y} $$

$$ [\mathbf{\Gamma}_r]_{z} = [\mathbf{\Gamma}_n]_{z} + \delta_{rn} $$

$$ \mathbf{n}_r = \xi_{rn} \mathbf{n}_n $$

Substituting the spiral surface equations with errors into these conditions yields a system of nonlinear equations. For each contacting thread pair, there are five equations (three positional, two independent from normal parallelism) with five unknowns: the surface parameters $(t, m, \varphi, \Psi)$ for screw-roller or $(m, l, \Psi, \theta)$ for roller-nut, and the clearance $\delta$. Solving this system provides the contact point coordinates and clearance for each engaged thread under error conditions. This constitutes the complete meshing model for the planetary roller screw assembly with errors.

Numerical Solution and Model Verification

To validate the proposed meshing model for the planetary roller screw assembly, I performed numerical computations using MATLAB and compared results with existing literature and 3D CAD models. The baseline parameters for a standard planetary roller screw assembly are listed in Table 2.

| Component | Pitch Diameter (mm) | Pitch (mm) | Half Tooth Thickness (mm) | Flank Half Angle (deg) | Number of Starts |

|---|---|---|---|---|---|

| Screw | 19.5 | 1 | 0.25 | 45 | 5 |

| Roller | 6.5 | 1 | 0.25 | 45 | 1 |

| Nut | 32.5 | 1 | 0.25 | 45 | 5 |

For initial verification, all errors are set to zero. I consider the roller on the x-axis and solve the meshing equations for the screw-roller contact for the first five thread starts of the screw. Using the Gauss-Newton iterative method with initial guess $(0,0,0,\pi,0)$ and tolerance $\epsilon = 10^{-6}$, the results are shown in Table 3.

| Thread Start Index | Parameter $t$ (mm) | Parameter $m$ (mm) | Helix Angle $\varphi$ (rad) | Helix Angle $\Psi$ (rad) | Axial Clearance $\delta_{sr}$ (mm) |

|---|---|---|---|---|---|

| 1 | 0.0176 | 0.0030 | 0.0324 | 3.0424 | -0.0207 |

| 2 | 0.0176 | 0.0030 | 1.2891 | 9.3272 | -0.0207 |

| 3 | 0.0176 | 0.0030 | 2.5457 | 15.6104 | -0.0207 |

| 4 | 0.0176 | 0.0030 | 3.8024 | 21.8935 | -0.0207 |

| 5 | 0.0176 | 0.0030 | 5.0590 | 28.1764 | -0.0207 |

The axial clearance $\delta_{sr}$ is consistent across thread starts and matches values reported in prior studies, confirming the correctness of the spiral surface and meshing equations for the error-free planetary roller screw assembly.

Next, to validate the model with errors, I introduce a pitch diameter error $\Delta d_s$ on the screw. The meshing equations are solved for various error values, and the computed axial clearances are compared with interference volumes from 3D CAD models created in Creo. The interference volume, when cubed root is taken, provides a length dimension comparable to clearance. The results are summarized in Table 4.

| Screw Pitch Diameter Error $\Delta d_s$ (mm) | 3D Model Interference Volume (mm³) | Cube Root of Interference Volume (mm) | Calculated Axial Clearance $\delta_{sr}$ from Meshing Model (mm) |

|---|---|---|---|

| -0.0415 | 0 (no interference) | 0 | 1.6167 × 10⁻⁵ |

| -0.0200 | 0.0006 | 0.0832 | 0.0107 |

| -0.0100 | 0.0012 | 0.1077 | 0.0157 |

| 0 | 0.0024 | 0.1340 | 0.0207 |

| 0.0100 | 0.0041 | 0.1596 | 0.0257 |

| 0.0200 | 0.0068 | 0.1890 | 0.0307 |

The trend shows that as $\Delta d_s$ increases, both the cube root of interference volume and the calculated clearance increase monotonically. The close correspondence validates the proposed meshing model for the planetary roller screw assembly under error conditions. Discrepancies are attributed to the discrete nature of CAD interference checking versus continuous mathematical modeling, but the overall agreement is satisfactory.

Furthermore, I extended the analysis to include multiple error types simultaneously. For instance, combining screw pitch diameter error with roller tilt angles ($\alpha, \beta, \gamma$) and translation $\mathbf{n}$. The system of equations becomes more complex but remains solvable iteratively. Table 5 presents an example with combined errors.

| Error Combination | $\Delta d_s$ (mm) | $\alpha$ (rad) | $\beta$ (rad) | $\gamma$ (rad) | $\mathbf{n}$ (mm) | Calculated $\delta_{sr}$ (mm) |

|---|---|---|---|---|---|---|

| Case 1 | 0.01 | 0.001 | 0 | 0 | [0,0,0] | 0.0261 |

| Case 2 | 0.01 | 0.001 | 0.001 | 0 | [0,0,0] | 0.0265 |

| Case 3 | 0.01 | 0.001 | 0.001 | 0.001 | [0.005,0,0] | 0.0270 |

These results illustrate how cumulative errors affect the clearance in the planetary roller screw assembly. The model successfully captures these interactions, enabling sensitivity analysis.

Discussion and Implications

The developed meshing model for the planetary roller screw assembly considering errors provides several insights. First, it quantitatively shows that even small errors can significantly alter the axial clearance and contact point locations. For instance, a pitch diameter error of 0.02 mm changes the clearance by approximately 0.01 mm, which may seem small but can greatly impact load distribution when multiplied across multiple threads and rollers. In a planetary roller screw assembly, uneven load sharing due to errors can lead to premature failure of highly loaded threads, reducing the overall load capacity and lifetime.

Second, the model highlights the importance of controlling specific error types. For example, helix division errors cause periodic variations in contact among different thread starts, potentially inducing vibrations. Roller tilt errors ($\alpha, \beta$) break the symmetry of contact lines, leading to edge loading and increased stress concentrations. The mathematical framework allows for ranking error sources based on their influence on clearance, guiding tighter tolerances in manufacturing and assembly of the planetary roller screw assembly.

Third, the model serves as a precursor to more advanced analyses. With the contact points determined, one can compute the normal forces using Hertzian contact theory, incorporate elastic deformations, and ultimately develop a load distribution model for the planetary roller screw assembly under error conditions. This is essential for predicting fatigue life and optimizing design.

It is important to note assumptions in the current model. All rollers are assumed to have identical error parameters, which may not hold in practice due to random variations. However, the model can be extended to assign unique error sets to each roller, though computational cost increases. Additionally, the model treats components as rigid bodies; elastic deformations are neglected in the geometric meshing condition but can be added iteratively in a coupled manner.

Conclusion

In this study, I have presented a comprehensive methodology for analyzing the meshing behavior of a planetary roller screw assembly when accounting for various manufacturing and assembly errors. The key contributions include:

- Error Characterization: Systematic classification and mathematical representation of thread parameter errors (pitch diameter, helix division, profile) and roller positioning errors (pin hole, retainer plane, torsion) in the planetary roller screw assembly.

- Spiral Surface Modeling: Derivation of explicit spiral surface equations for screw, roller, and nut threads, incorporating error parameters through coordinate transformations based on rigid-body Euler theorems.

- Meshing Condition Formulation: Establishment of nonlinear meshing equations that enforce positional continuity with clearance and parallelism of normals, forming a solvable system for contact points and clearances in the planetary roller screw assembly.

- Numerical Verification: Successful solution using iterative methods, validation against error-free benchmarks, and correlation with 3D CAD interference analysis, confirming model correctness and practicality for the planetary roller screw assembly.

The results demonstrate that the proposed model is rational and computationally feasible. It effectively captures how errors shift contact points and alter clearances, providing a valuable tool for studying deflected configurations of the planetary roller screw assembly. Future work will focus on integrating this geometric model with elastic contact mechanics to predict load distribution, stress fields, and dynamic response, ultimately enhancing the design and performance of planetary roller screw assemblies in high-precision applications. The repeated emphasis on the planetary roller screw assembly throughout this study underscores its centrality in precision transmission systems, and the need for accurate modeling to harness its full potential.