In the realm of precision mechanical transmission systems, the planetary roller screw assembly represents a pivotal technology for converting rotary motion into linear motion with high efficiency, load capacity, and durability. My focus in this extensive discussion is on a specific variant: the inverted planetary roller screw assembly (IPRSM). This mechanism, while sharing fundamental principles with the standard planetary roller screw assembly, offers unique advantages such as compactness, reduced mass, and rapid frequency response, making it exceptionally suitable for applications where space and weight are critical constraints, like aerospace actuators, advanced machine tools, and medical devices. Throughout this article, I will delve into the comprehensive design methodology, kinematic analysis, parameter determination, and the intricate process of virtual assembly for the inverted planetary roller screw assembly. I aim to provide a detailed resource that underscores the importance of meticulous design in harnessing the full potential of the planetary roller screw assembly.

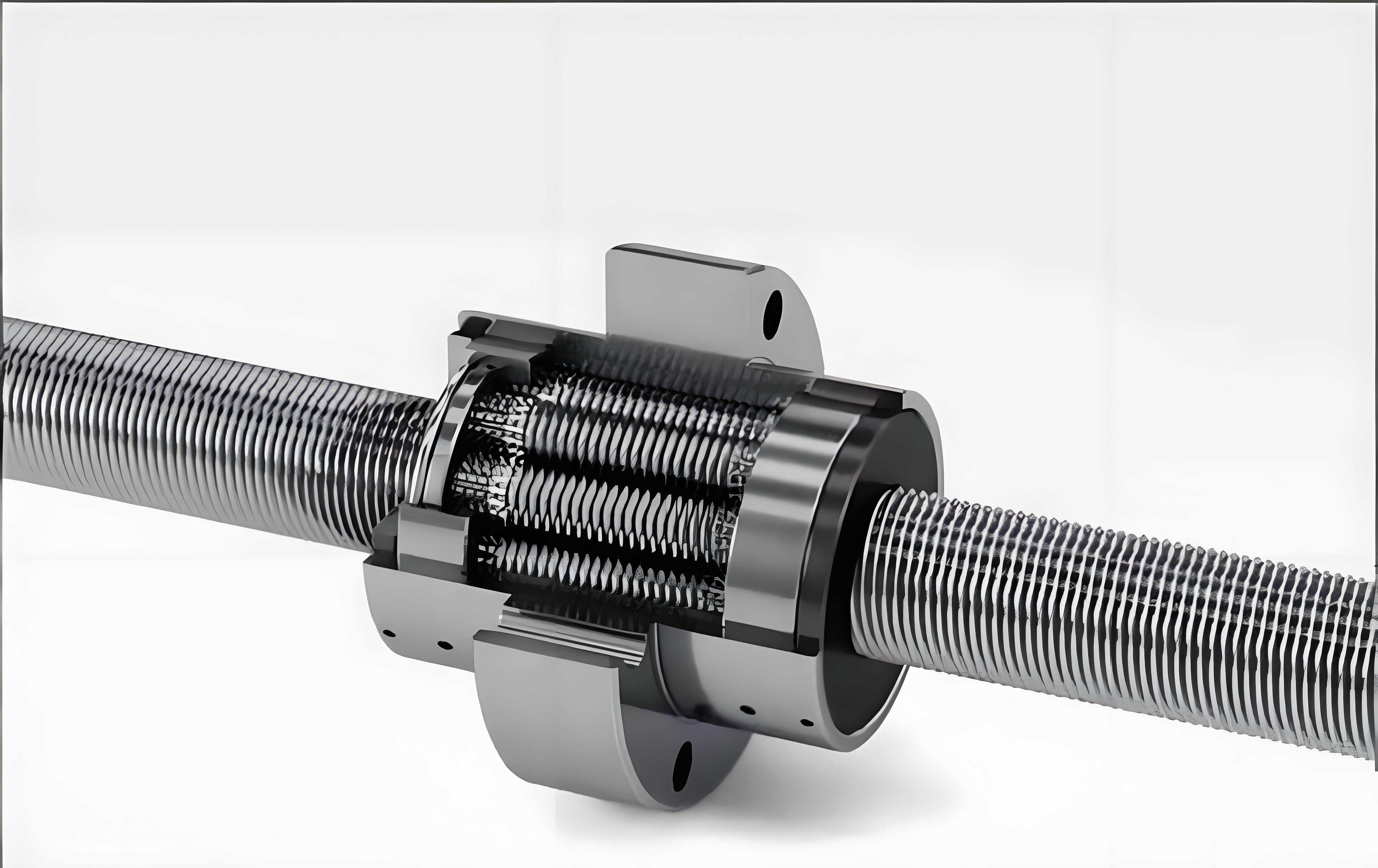

The core structure of the inverted planetary roller screw assembly consists of several key components: a long nut, multiple rollers, a hollow screw, a retainer (or cage), and a push rod. In this configuration, the long nut serves as the input member, rotating under motor drive, while the hollow screw translates axially to produce linear output via the push rod. The rollers are the essential intermediate elements, arranged circumferentially around the hollow screw and meshing with both the nut and the screw through threaded engagements. A critical feature of the planetary roller screw assembly is the design of the roller threads, which typically feature a circular arc profile to ensure point contact with the nut and screw threads, minimizing friction and wear. Additionally, both ends of each roller and the hollow screw are equipped with gear teeth—helical on the rollers and spur on the screw—to counteract tilting moments induced by the helix angles and prevent axial slippage. This intricate interplay of components defines the operational essence of the inverted planetary roller screw assembly.

Designing an inverted planetary roller screw assembly requires a systematic approach that ensures compatibility among all parts. The design process essentially revolves around the roller, as its parameters dictate the dimensions of the nut and screw. I begin by establishing the roller’s pitch diameter, which is derived from application-specific requirements like speed and thrust. The number of thread starts and the pitch are also determined at this stage. For the planetary roller screw assembly to function correctly, the threads on the nut, screw, and roller must have matching pitches, but different numbers of starts. Specifically, the nut and hollow screw share the same number of thread starts, while the roller typically has a single start. The relationship governing the pitch diameters is fundamental:

$$ d_n = d_s + 2d_r $$

where \( d_n \) is the pitch diameter of the nut, \( d_s \) is the pitch diameter of the hollow screw, and \( d_r \) is the pitch diameter of the roller. The number of thread starts for the nut and screw, denoted as \( n \), relates to these diameters as follows:

$$ n = \frac{d_s}{d_r} $$

This equation highlights the geometric interdependence within the planetary roller screw assembly. The roller’s thread profile is not triangular like that of the nut and screw; instead, it features a circular arc to facilitate point contact. The radius of this arc, \( R \), is calculated based on the roller’s pitch diameter:

$$ R = \frac{d_r}{2 \sin 45^\circ} $$

Ensuring that the roller’s gear tip diameter does not exceed its thread major diameter is crucial for assembly clearance. The gear parameters are equally important. The roller’s helical gear and the screw’s spur gear must mesh properly, with their pitch diameters equal to the thread pitch diameters of the respective parts. Thus:

$$ d_r = d_{l} = m z_r $$

$$ d_s = d_{z} = m z_s $$

Here, \( d_{l} \) is the pitch diameter of the roller’s helical gear, \( d_{z} \) is the pitch diameter of the screw’s spur gear, \( m \) is the gear module, \( z_r \) is the number of teeth on the roller gear, and \( z_s \) is the number of teeth on the screw gear. To avoid undercutting in gear teeth, the minimum number of teeth is given by:

$$ z_{\text{min}} = \frac{2 h_a^*}{\sin^2 \alpha_n} $$

where \( h_a^* \) is the addendum coefficient (usually 1 for full-depth teeth) and \( \alpha_n \) is the pressure angle. Proper selection of these parameters ensures smooth operation of the planetary roller screw assembly.

To summarize the key structural parameters, I present the following table, which encapsulates the typical relationships in an inverted planetary roller screw assembly:

| Component | Thread Starts | Thread Profile | Lead Relationship | Gear Type |

|---|---|---|---|---|

| Hollow Screw | \( n_s \) | Triangular (90°) | \( L_s = n_s P \) | Spur Gear |

| Long Nut | \( n_n = n_s \) | Triangular (90°) | \( L_n = L_s \) | None |

| Roller | 1 | Circular Arc | \( L_r = P \) | Helical Gear |

Another critical aspect is the lead, which must be consistent across the assembly. The lead \( L \) is the axial distance traveled per revolution of the nut. For the nut and screw, the lead is the product of the number of starts and the pitch \( P \), while for the single-start roller, the lead equals the pitch. Hence, the pitch is uniform: \( P_s = P_n = P_r = P \). This uniformity is vital for synchronized motion in the planetary roller screw assembly.

Moving to kinematic analysis, understanding the motion of components within the inverted planetary roller screw assembly is essential for predicting performance. When the long nut rotates with an angular velocity \( \omega_n \), the rollers undergo both planetary motion (revolution around the screw axis) and rotation about their own axes. The hollow screw is constrained from rotating, so it translates axially. Let \( \omega_c \) be the angular velocity of the roller’s revolution (carrier angular velocity) and \( \omega_r \) be the angular velocity of the roller’s rotation (spin). From geometric considerations, the relationship between the nut’s rotation and the roller’s revolution can be derived. Considering the pitch diameters, the roller’s revolution velocity is:

$$ \omega_c = \frac{d_n}{2 d_c} \omega_n = \frac{d_s + 2d_r}{2(d_s + d_r)} \omega_n $$

where \( d_c = d_s + d_r \) is the diameter of the roller’s revolutionary path. Substituting \( n = d_s / d_r \), this simplifies to:

$$ \omega_c = \frac{n + 2}{2(n + 1)} \omega_n $$

For the roller’s spin, since there is pure rolling contact between the roller and the hollow screw, the arc lengths rolled are equal. This yields the ratio of rotation angles:

$$ \frac{\phi_r}{\phi_c} = \frac{d_s}{d_r} = n $$

where \( \phi_r \) and \( \phi_c \) are the rotation and revolution angles, respectively. Consequently, the angular velocity ratio is the same:

$$ \frac{\omega_r}{\omega_c} = n $$

Combining these equations, the roller’s spin angular velocity is:

$$ \omega_r = n \omega_c = \frac{n(n + 2)}{2(n + 1)} \omega_n $$

These kinematic equations are fundamental for analyzing the dynamics of the planetary roller screw assembly, especially in applications requiring precise motion control.

The number of rollers in an inverted planetary roller screw assembly significantly affects its load capacity, stiffness, and overall performance. Rollers are typically arranged symmetrically around the screw to ensure even load distribution. The choice of roller count depends on geometric constraints and the desired mechanical advantage. Common configurations are influenced by the number of thread starts on the nut and screw. Based on design practice, I have compiled a table of typical parameter matching combinations for the planetary roller screw assembly:

| Number of Thread Starts (Nut/Screw) | Nut to Screw Diameter Ratio | Roller to Screw Diameter Ratio | Typical Number of Rollers |

|---|---|---|---|

| \( n_s = 3 \) | \( d_n = 3 d_s \) | \( d_r = d_s \) | 4, 5 |

| \( n_s = 4 \) | \( d_n = 2 d_s \) | \( d_r = d_s / 2 \) | 7, 8, 9 |

| \( n_s = 5 \) | \( d_n = (5/3) d_s \) | \( d_r = d_s / 3 \) | 7 to 12 |

Selecting a higher number of rollers generally enhances the load-bearing capability of the planetary roller screw assembly, but it must be balanced against manufacturing complexity and assembly feasibility. The rollers are held in place by a retainer that maintains their circumferential spacing. The angular position of each roller is crucial for proper meshing. For \( z \) rollers evenly spaced, the angle between adjacent rollers is \( \phi = 360^\circ / z \). However, due to the helical nature of the gears, each roller must be oriented correctly relative to the screw’s gear teeth to ensure simultaneous engagement of both threads and gears. This aspect is critical during virtual assembly of the planetary roller screw assembly.

Virtual assembly and 3D modeling are indispensable steps in the design validation of an inverted planetary roller screw assembly. Using CAD software like SolidWorks, I create detailed parametric models of each component. The process begins with the roller, as its dimensions drive the rest. For instance, consider a design example with the following parameters: hollow screw pitch diameter \( d_s = 20 \, \text{mm} \), lead \( L_s = 5.08 \, \text{mm} \), and number of starts \( n_s = 4 \). Then, the pitch is \( P = L_s / n_s = 1.27 \, \text{mm} \). The roller pitch diameter is \( d_r = d_s / n_s = 5 \, \text{mm} \). For the gears, choosing a module \( m = 0.25 \, \text{mm} \), the screw gear teeth number is \( z_s = 80 \), and the roller gear teeth number is \( z_r = 20 \), satisfying the ratio \( z_s / z_r = n_s = 4 \). The nut pitch diameter is \( d_n = d_s + 2d_r = 30 \, \text{mm} \).

Modeling the threads requires careful attention. For the nut and screw, the thread profile is a 90° triangular shape, while for the roller, it is a circular arc. In CAD, I use helical sweep cuts to generate these threads. The helix is defined based on the pitch diameter and lead. To avoid interference in the planetary roller screw assembly, the thread root widths should be consistent across components. This may require fine-tuning the tooth thickness parameters. The gear teeth are modeled using standard gear generation tools, ensuring proper involute profiles. Once individual parts are modeled, assembly begins.

Virtual assembly of the inverted planetary roller screw assembly is a meticulous process due to the need for simultaneous thread and gear meshing. The key is to align the starting points of threads and the gear teeth orientations. I start by fixing the hollow screw. Then, I insert the first roller such that its axis is at the correct center distance from the screw axis. The roller must be positioned so that its helical gear teeth mesh with the screw’s spur gear teeth at both ends. This involves aligning reference planes or axes. Specifically, if the screw’s gear tooth space center plane is defined, the roller’s gear tooth center plane should coincide with it. After securing the first roller, additional rollers are added at evenly spaced angular positions around the screw. However, because of the helix angle, each subsequent roller must be rotated about its own axis to account for the phase difference. For a roller at position \( i \) (with \( i = 1, 2, \dots, z \)), the revolution angle relative to the first roller is:

$$ \theta_i = (i – 1) \phi $$

where \( \phi \) is the angular spacing. The corresponding self-rotation angle \( \beta_i \) to ensure proper gear engagement is related to the number of thread starts:

$$ \beta_i = n \theta_i $$

In practice, for the example with \( n = 4 \) and \( \phi = 45^\circ \) (for 8 rollers), the self-rotation angles modulo 360° become 0°, 180°, 0°, 180°, etc. Adjusting these to 0° for all rollers simplifies assembly while maintaining correctness. The retainer is then assembled to hold the rollers in position. Finally, the long nut is placed over the rollers, ensuring its internal threads mesh with the roller threads. This virtual assembly process validates the design and reveals any interferences, ensuring that the planetary roller screw assembly will function smoothly in reality.

To further illustrate the design parameters, I present a detailed table of component dimensions for the example inverted planetary roller screw assembly:

| Component | Major Diameter (mm) | Pitch Diameter (mm) | Minor Diameter (mm) | Starts | Pitch (mm) | Gear Module (mm) | Gear Teeth |

|---|---|---|---|---|---|---|---|

| Roller | 5.4 | 5.0 | 4.45 | 1 | 1.27 | 0.25 | 20 |

| Hollow Screw | 20.55 | 20.0 | 19.6 | 4 | 1.27 | 0.25 | 80 |

| Long Nut | 30.55 | 30.0 | 29.6 | 4 | 1.27 | — | — |

Beyond the basic design, several advanced considerations impact the performance of the planetary roller screw assembly. For instance, load distribution among the rollers is critical for longevity. Using finite element analysis (FEA), one can model the contact stresses at the thread interfaces. The point contact between the roller’s arc-shaped threads and the nut/screw threads leads to Hertzian contact stresses. Optimizing the arc radius \( R \) can help minimize these stresses. Additionally, thermal effects due to friction can cause expansion and alter clearances; thus, thermal analysis is essential for high-precision applications of the planetary roller screw assembly. The efficiency of the mechanism, which is typically high due to rolling contact, can be estimated by accounting for losses in the gear meshes and thread contacts. Mathematical modeling of these aspects involves complex equations, but simplified models can provide insights. For example, the axial stiffness of the planetary roller screw assembly can be approximated by considering the combined stiffness of all roller contacts in series and parallel arrangements.

The manufacturing tolerances and alignment errors also play a significant role in the functionality of the inverted planetary roller screw assembly. Misalignment can lead to uneven load sharing, increased wear, and reduced accuracy. Therefore, during virtual assembly, it is prudent to perform tolerance stack-up analysis using CAD tools. This ensures that even with manufacturing variances, the assembly will still operate correctly. Furthermore, the material selection for components—such as high-strength alloy steel for the screw and rollers, and possibly lighter materials for the nut in aerospace applications—affects the weight and performance of the planetary roller screw assembly. Surface treatments like nitriding or coating can enhance wear resistance and fatigue life.

In terms of applications, the inverted planetary roller screw assembly is particularly advantageous in electromechanical actuators (EMAs) where integration with a motor is desired. The long nut can be designed to incorporate permanent magnets, serving directly as the motor rotor. This integrated design reduces the number of parts, minimizes backlash, and improves dynamic response. Such compact actuators are increasingly used in flight control systems, robotic joints, and precision positioning stages. The ability of the planetary roller screw assembly to handle high loads with minimal wear makes it a reliable choice for these demanding environments.

To encapsulate the design methodology, I reiterate the flow: start with application requirements to determine the roller pitch diameter and basic leads. Then, select the number of thread starts for the nut and screw based on desired gear ratios and size constraints. Calculate all derived dimensions using the formulas provided. Model each component in CAD, paying close attention to thread and gear profiles. Assemble virtually by ensuring proper meshing of both threads and gears, adjusting phases as needed. Validate through interference checks and motion simulations. This comprehensive approach ensures a robust design for the inverted planetary roller screw assembly.

In conclusion, the inverted planetary roller screw assembly is a sophisticated transmission mechanism that offers superior performance in compact spaces. Through detailed design analysis, kinematic derivation, parameter optimization, and virtual assembly techniques, I have explored the intricacies of this system. The planetary roller screw assembly, in its inverted form, represents a significant advancement in motion control technology. By adhering to the design principles and methods discussed, engineers can develop reliable and efficient assemblies for a wide range of high-tech applications. Future work may focus on dynamic simulation, advanced material integration, and real-time condition monitoring to further enhance the capabilities of the planetary roller screw assembly. This deep dive into the design and virtual integration processes underscores the importance of precision engineering in realizing the full potential of the planetary roller screw assembly.