In the context of advancing transportation technologies, particularly under initiatives like the national strategy for building a strong transportation network, there is a pressing need for innovative braking solutions in commercial vehicles. Traditional electromechanical brake (EMB) systems, which often rely on gear trains combined with ball screws, face significant challenges such as low transmission efficiency, excessive heat generation, short service life, and inadequate stiffness. These limitations become critical in heavy-duty applications like trucks, where reliability and safety are paramount. To address these issues, I have embarked on a project to develop a novel planetary roller screw assembly tailored for high-load, high-stability performance in EMB systems. This planetary roller screw assembly leverages multi-point spiral surface meshing transmission to replace conventional point and line contacts, thereby enhancing load capacity, longevity, and efficiency. Throughout this work, I focus on optimizing the design, material selection, and heat treatment processes, supported by rigorous testing and analysis. The goal is to provide a more efficient and durable solution for commercial vehicle parking brake systems, contributing to the broader adoption of EMB technology.

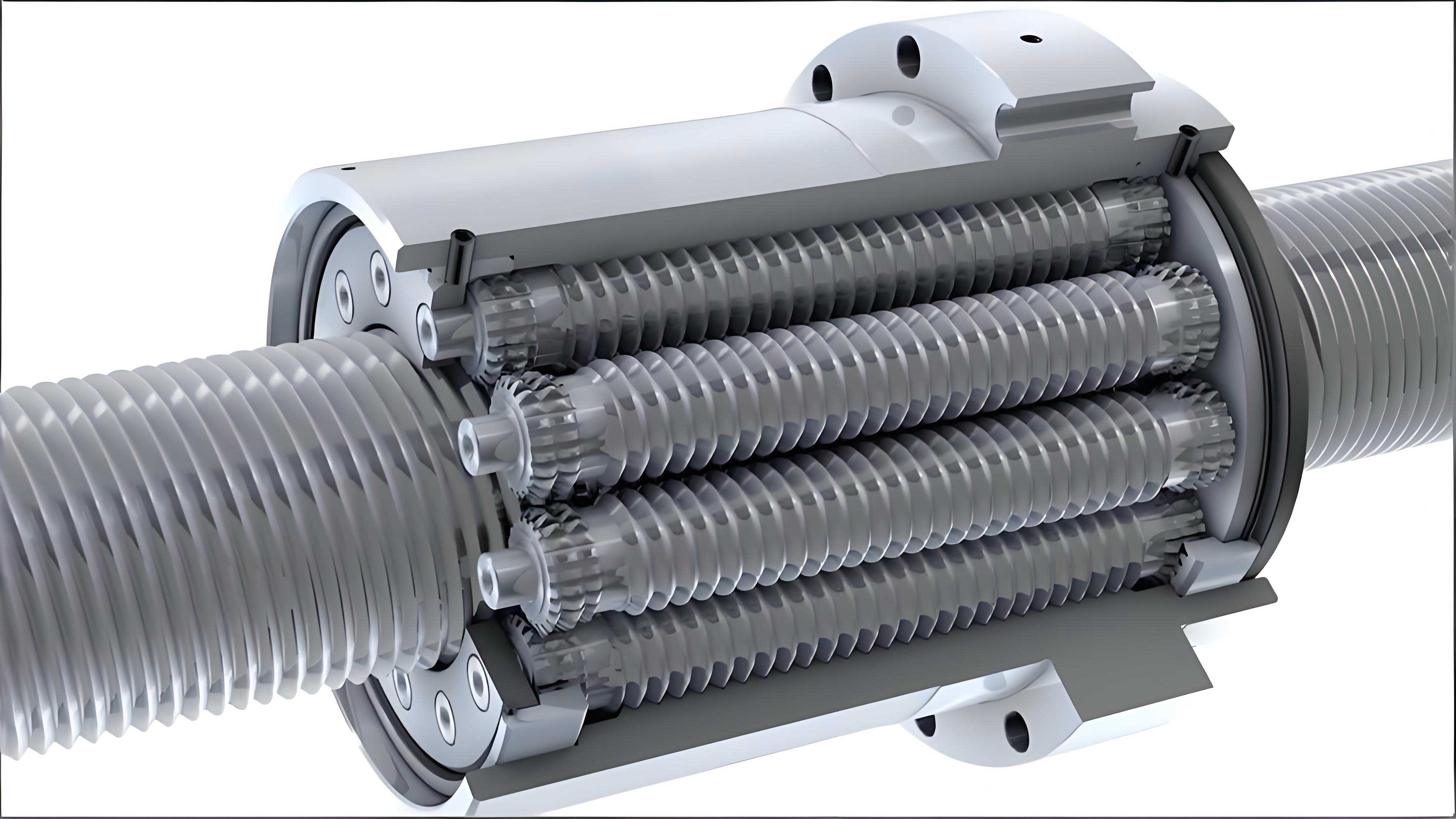

The core innovation lies in the planetary roller screw assembly, which consists of a screw, multiple rollers, and a nut arranged in a planetary configuration. Unlike ball screws that use balls for motion transmission, this planetary roller screw assembly employs threaded rollers that engage with both the screw and nut threads, distributing loads more evenly. This design fundamentally improves the mechanical performance under heavy loads. In this article, I will detail the design and manufacturing processes, material choices, heat treatment techniques, and experimental evaluations that underpin the development of this advanced planetary roller screw assembly. I will also incorporate tables and formulas to summarize key findings, ensuring a comprehensive understanding of its superiority over existing systems.

Starting with the design phase, I selected a standard-type planetary roller screw assembly due to its suitability for harsh environments, high loads, and long linear travels. This planetary roller screw assembly typically includes a central screw, planetary rollers arranged around it, and a nut that houses the rollers. To enhance performance, I adopted a concave circular arc tooth profile for the screw and nut, while the rollers feature a convex circular arc structure. This convex-concave contact ensures better load distribution and reduces stress concentrations. The contact stress analysis was conducted using finite element methods (FEM), which revealed uneven load distribution across the thread teeth. Specifically, the first engaged thread tooth experiences the highest equivalent stress, with subsequent teeth showing递减 stress levels. This insight guided several optimization measures to improve the planetary roller screw assembly’s durability and efficiency.

Based on FEM results, I implemented design refinements to address load imbalances. The equivalent stress cloud maps indicated that the initial thread teeth bore excessive stress, leading to potential wear and failure. To mitigate this, I adjusted the number of thread starts and the thread angle, which helped redistribute loads more uniformly. Additionally, I optimized the arrangement and assembly of the planetary rollers. For instance, on the left side, I used shims to control axial spacing, while on the right side, thrust bearings were incorporated to reduce wear and eliminate the need for alignment blocks. The roller retention holes were changed from slotted to circular designs for better precision control, secured with axial clips at both ends. These modifications significantly enhanced the structural integrity of the planetary roller screw assembly, ensuring smoother operation under heavy loads.

Furthermore, I introduced specialized structural features to cope with demanding conditions such as heavy loads and dusty environments. One key innovation is a self-adjusting gap spring collar integrated into the planetary roller screw assembly. This spring collar utilizes internal tension to automatically compensate for wear-induced gaps between the rollers and screw, maintaining transmission accuracy over time. Another feature involves combining this collar with a felt ring seal. The felt ring has a slightly smaller inner diameter than the cover plate, allowing it to sweep along the screw during operation. This design prevents external dust and debris from entering the planetary roller screw assembly while sealing in lubricating oil, thereby improving cleanliness and lubrication. These additions are crucial for the planetary roller screw assembly’s longevity in real-world applications like commercial vehicle braking.

To quantify the design improvements, I derived formulas for contact stress and transmission efficiency. The contact stress $\sigma_c$ in the planetary roller screw assembly can be approximated using Hertzian contact theory:

$$ \sigma_c = \sqrt{\frac{F E^*}{\pi R^*}} $$

where $F$ is the applied load, $E^*$ is the equivalent Young’s modulus, and $R^*$ is the equivalent radius of curvature. For the convex-concave contact in our planetary roller screw assembly, $R^*$ is adjusted based on the arc radii. The transmission efficiency $\eta$ of the planetary roller screw assembly is given by:

$$ \eta = \frac{P_{\text{out}}}{P_{\text{in}}} = \frac{F v}{T \omega} $$

where $P_{\text{out}}$ is the output power (force $F$ times linear velocity $v$), $P_{\text{in}}$ is the input power (torque $T$ times angular velocity $\omega$). These formulas guide the optimization of load capacity and efficiency in the planetary roller screw assembly.

Moving to material selection, the planetary roller screw assembly requires components—screw, rollers, and nut—that exhibit high strength, hardness, wear resistance, and thermal stability. I evaluated two candidate materials: high-carbon chromium bearing steel GCr15 and advanced nitriding steel 38CrMoAlA. Through comparative testing, I found that GCr15, while hard (over HRC 70 after heat treatment), tended to develop chipped thread tips under high loads due to its brittleness. In contrast, 38CrMoAlA, after quenching and tempering to HRC 35-38 and subsequent soft nitriding, achieved a tough core with a hard surface, minimizing thermal deformation and maintaining an outer roundness jump of less than 0.01 mm. This material choice for the planetary roller screw assembly resulted in better transmission efficiency and durability. The table below summarizes the key properties of these materials:

| Material | Hardness (After Treatment) | Wear Resistance | Impact Toughness | Suitability for Planetary Roller Screw Assembly |

|---|---|---|---|---|

| GCr15 | > HRC 70 | High | Low (brittle) | Limited due to chipping risk |

| 38CrMoAlA | ~800 HV (soft nitrided) | Excellent | High (tough core) | Ideal for high-load applications |

For heat treatment, I explored various processes to enhance the surface properties of the planetary roller screw assembly components. After iterative testing, I selected soft nitriding (low-temperature nitrogen-carbon co-penetration) for its balance of hardness, wear resistance, and dimensional stability. Compared to alternatives like QPQ treatment, hard nitriding, and high-frequency quenching, soft nitriding involves lower temperatures and shorter times, resulting in minimal dimensional changes (errors below 0.01 mm) and a hardened layer thickness of about 0.25 mm with a hardness of approximately 800 HV. This process is particularly beneficial for the planetary roller screw assembly as it prevents thread tip damage under impact loads while ensuring longevity. To optimize the soft nitriding parameters, I conducted orthogonal experiments varying salt bath temperature, holding time, and salt bath composition. The factors and levels are summarized in the following table:

| Factor | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 |

|---|---|---|---|---|---|

| Salt Bath Temperature (°C) | 400 | 450 | 500 | 550 | 600 |

| Holding Time (h) | 4 | 2 | 4 | 2 | 4 |

| Salt Bath Ratio | Nitrogen-rich | Carbon-nitrogen balanced | Nitrogen-rich | Carbon-nitrogen balanced | Carbon-rich |

| Surface Hardness (HV0.2) | 766 | 570 | 658 | 392 | 623 |

| Hardened Layer Depth (mm) | 0.25 | 0.30 | 0.30 | 0.32 | 0.45 |

The optimal parameters for the planetary roller screw assembly were determined as a salt bath temperature of 420°C and a holding time of 4 hours, yielding a hardened layer depth of 0.25 mm with excellent wear resistance. This heat treatment process ensures that the planetary roller screw assembly components maintain their precision and strength under cyclic loading.

To evaluate the performance of the developed planetary roller screw assembly, I conducted a series of tests including static load capacity, dynamic efficiency, thread precision, hardness measurement, and fatigue wear analysis. These experiments were performed on dedicated test benches, simulating real-world EMB conditions. For static load testing, I applied axial loads via a hydraulic cylinder to determine the maximum static load. The planetary roller screw assembly consistently withstood loads exceeding 10,000 N, well above the design requirement of 9,800 N, with no significant travel errors or thread deformation. This confirms the robustness of the planetary roller screw assembly under high stress.

Dynamic efficiency testing involved measuring input torque and output load to calculate transmission efficiency. The results showed that the planetary roller screw assembly achieved efficiencies between 0.809 and 0.846 under tension, and between 0.728 and 0.796 under compression. These values indicate high efficiency, contributing to reduced heat generation in EMB systems. The efficiency can be modeled using the formula:

$$ \eta_{\text{dynamic}} = 1 – \frac{W_{\text{loss}}}{W_{\text{in}}} $$

where $W_{\text{loss}}$ represents energy losses due to friction and wear in the planetary roller screw assembly. The low losses observed highlight the effectiveness of the multi-point meshing design.

Thread precision was assessed using a universal tool microscope to measure wear and dimensional accuracy. After testing, the thread teeth showed no plastic deformation, with single-tooth errors not exceeding 0.005 mm, far below the design limit of 0.002 mm. This precision is critical for the reliable operation of the planetary roller screw assembly in braking applications. Additionally, hardness testing verified the effectiveness of the soft nitriding process, with surface hardness values around 800 HV ensuring durability.

Fatigue and wear analysis were conducted by installing the planetary roller screw assembly in an EMB test rig for 5,000 cycles under a maximum thrust of 13,720 N. Post-test examination revealed minimal wear, particularly on the thread tips, demonstrating the planetary roller screw assembly’s resistance to fatigue. The soft nitriding treatment played a key role in this performance, as evidenced by the negligible deformation observed. The wear rate $w$ can be expressed as:

$$ w = \frac{\Delta V}{N L} $$

where $\Delta V$ is the volume loss, $N$ is the number of cycles, and $L$ is the load. For our planetary roller screw assembly, $w$ was extremely low, indicating superior wear resistance. The table below summarizes key test results for the planetary roller screw assembly:

| Test Type | Parameter | Result | Design Target | Implication for Planetary Roller Screw Assembly |

|---|---|---|---|---|

| Static Load Test | Maximum Static Load | >10,000 N | 9,800 N | Exceeds requirements, high load capacity |

| Dynamic Efficiency Test | Efficiency under Tension | 0.809–0.846 | High efficiency desired | Reduces heat buildup in EMB |

| Dynamic Efficiency Test | Efficiency under Compression | 0.728–0.796 | High efficiency desired | Ensures reliable braking performance |

| Thread Precision Test | Single-Tooth Error | <0.005 mm | <0.002 mm | Maintains accuracy over time |

| Hardness Test | Surface Hardness | ~800 HV | High hardness for wear resistance | Enhanced durability |

| Fatigue Test | Cycles Completed | 5,000 cycles | 5,000 cycles target | No significant wear, excellent fatigue life |

The successful completion of these tests validates the planetary roller screw assembly as a high-performance component for EMB systems. Its ability to handle heavy loads while maintaining efficiency and precision makes it a superior alternative to traditional ball screws. Moreover, the self-adjusting gap mechanism and dust sealing features further enhance its reliability in challenging environments.

In conclusion, the development of this novel planetary roller screw assembly represents a significant advancement in electromechanical braking technology. By leveraging multi-point spiral surface meshing, optimized materials, and advanced heat treatment, I have created a planetary roller screw assembly that offers high load capacity, long service life, improved transmission efficiency, strong impact resistance, self-adjusting clearance, self-locking capability, and lightweight design. These attributes directly address the limitations of existing EMB systems, such as low efficiency and excessive heat generation. The planetary roller screw assembly has demonstrated excellent performance in rigorous testing, with a braking thrust capability of up to 13,720 N and minimal wear over 5,000 cycles. This makes it an ideal solution for commercial vehicle parking brake systems, contributing to safer and more reliable transportation. Future work may focus on further scaling the planetary roller screw assembly for other high-load applications and exploring integration with smart braking controls. Overall, the planetary roller screw assembly stands out as a key innovation in the pursuit of efficient and durable electromechanical braking solutions.