In this comprehensive article, I will explore the intricacies of planetary roller screw assemblies, a mechanical transmission component that has garnered attention for its potential high load capacity and smooth operation. The planetary roller screw assembly was first invented in the mid-20th century, yet its widespread adoption has been limited due to structural complexity and reliability concerns. Through this analysis, I aim to provide a thorough understanding of its design, performance comparison with ball screw assemblies, factors affecting its load-bearing capabilities, and its applicability in critical fields such as aerospace. The keyword ‘planetary roller screw assembly’ will be emphasized throughout to highlight its significance.

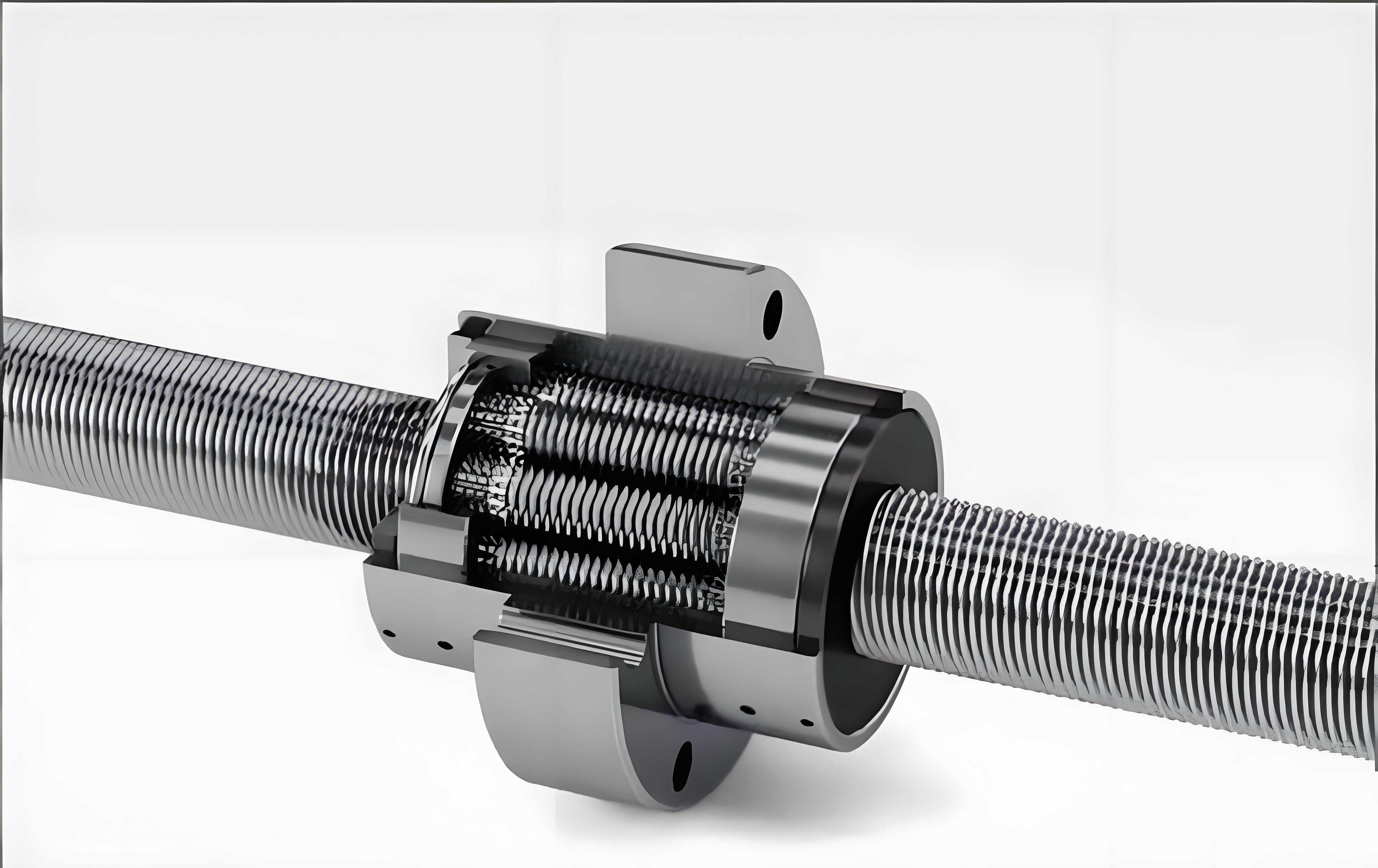

The planetary roller screw assembly operates on a principle akin to planetary gearing systems, where multiple threaded rollers engage with a central threaded screw and a surrounding threaded nut. This configuration allows for rolling contact, which theoretically reduces friction and enhances efficiency. However, the actual performance of a planetary roller screw assembly is highly dependent on manufacturing precision and design tolerances. I will delve into the structural components, starting with the screw, nut, rollers, internal gear ring, pressure cover, and retaining ring. Each part plays a critical role in ensuring the proper functioning of the planetary roller screw assembly.

To understand the working mechanism, consider the kinematics: when the screw rotates, the rollers both revolve around the screw axis (planetary motion) and rotate about their own axes. This dual motion drives the nut axially, converting rotational input into linear output. The contact between the rollers and the screw/nut threads occurs at multiple points, which is a key advantage of the planetary roller screw assembly. However, this multi-point contact also introduces challenges in load distribution and reliability. The thread profiles typically involve a 90-degree tooth angle for the screw and nut, while the rollers feature a double convex arc profile. This design aims to optimize rolling friction, but imperfections can lead to uneven loading.

In comparing the planetary roller screw assembly with the more common ball screw assembly, several distinctions emerge. Below is a detailed table summarizing their differences, which I have compiled based on extensive research and practical observations.

| Aspect | Ball Screw Assembly | Planetary Roller Screw Assembly |

|---|---|---|

| Structural Composition | Consists of screw, nut, balls, and return tubes. The screw and nut have single or multi-start threads with single or double arc raceways. Simple structure. | Includes screw, nut, rollers, internal gear ring, pressure cover, and retaining ring. The screw and nut have multi-start threads with a 90-degree tooth angle, while rollers have single-start threads with double convex arcs. Complex structure. |

| Circulation Method | Balls circulate via return tubes forming ball chains, often with multiple chains for higher load capacity. | Rollers engage directly without return mechanisms, resembling planetary gear systems with multiple contact points. |

| Rolling Elements | Balls | Rollers |

| Overall Dimensions | Compact due to deep raceways embedding balls internally, resulting in smaller nut size. | Larger nut size because of shallow thread depth and larger roller diameter, increasing outer dimensions. |

| Motion Smoothness | Potential for impact and vibration as balls pass through return tubes, affecting smoothness. | Generally smoother operation due to absence of return mechanisms, reducing冲击 and vibration. |

| Transmission Efficiency | High efficiency, often exceeding 90%, due to low rolling friction and high precision of balls. | Efficiency typically below 90% due to加工 errors, surface roughness, and contact point inconsistencies in the planetary roller screw assembly. |

| Load Capacity | Lower for small sizes and leads; higher for large sizes and leads, especially with heavy-duty designs. | Theoretically higher for small sizes and leads due to multiple contact points, but实际承载 often lower due to manufacturing limitations. |

| Manufacturing and Assembly | Relatively simple processes with high precision achievable, leading to good reliability. | Complex processes involving multi-start thread machining, roller profiling, and assembly alignment, reducing reliability. |

| Reliability | High reliability due to简单 structure and成熟 technology. | Lower reliability because of structural complexity, sensitivity to errors, and potential for点接触 failures in the planetary roller screw assembly. |

The load-bearing capacity of a planetary roller screw assembly is a critical performance metric, influenced by numerous factors. I will analyze these factors in detail, incorporating mathematical models to illustrate the challenges. The theoretical load capacity is derived from contact mechanics, where each roller engages with the screw and nut threads. For a planetary roller screw assembly with n rollers and m thread starts, the total number of contact points can be expressed as:

$$ N_{total} = n \times m \times k $$

where k is the number of contact points per thread engagement (ideally 4 for preloaded assemblies, but often 2 due to clearance). However,实际承载 is reduced by various factors:

- Contact Point Integrity: In a preloaded planetary roller screw assembly, each roller should contact the screw and nut at four points per thread (two on each side of the 90-degree tooth). Due to diameter variations among rollers and assembly clearances, achieving uniform contact is difficult. The actual contact points may be fewer, leading to increased stress at those points. The contact stress can be estimated using Hertzian theory:

$$ \sigma_{max} = \sqrt{\frac{3F}{2\pi a b}} $$

where F is the load per contact point, and a and b are the semi-axes of the contact ellipse. If contact points are reduced, F increases, raising stress and reducing fatigue life.

- Tooth Angle and Half-Angle Errors: The 90-degree tooth angle of the screw and nut must be precise. Deviations in half-angle (e.g., 45° ± Δθ) cause misalignment, affecting contact symmetry and load distribution. The effective contact angle θeff can be modeled as:

$$ \theta_{eff} = 45^\circ \pm \Delta \theta $$

This error leads to uneven loading on the left and right flanks, compromising the planetary roller screw assembly’s bidirectional load capacity.

- Thread Start Division Errors: Multi-start threads require accurate angular division. Division errors δdiv result in some thread starts bearing more load than others. The load distribution factor α can be defined as:

$$ \alpha = \frac{m_{effective}}{m} $$

where meffective is the number of thread starts actually in contact. For a planetary roller screw assembly with significant division errors, α < 1, reducing overall load capacity.

- Roller Profile Radius and Center: The roller’s double convex arc profile must match the theoretical radius r and center position for optimal rolling. Deviations Δr and Δc cause slippage and increased friction. The kinematic condition for pure rolling is:

$$ r_{roller} = \frac{P_h}{2\pi} \cdot \frac{1}{\cos(\phi)} $$

where Ph is the lead and φ is the thread helix angle. Inaccuracies here degrade the efficiency and load capacity of the planetary roller screw assembly.

- Meshing Accuracy of Roller Ends and Internal Gear Ring: The external teeth on roller ends mesh with the internal gear ring to prevent tilting. Backlash or misalignment in this meshing allows roller skew, leading to edge loading and premature wear. The permissible skew angle β is limited by:

$$ \beta \leq \tan^{-1}\left(\frac{h}{L}\right) $$

where h is the thread depth and L is the roller length. Excessive skew disrupts the planetary motion in the planetary roller screw assembly.

- Lead Accuracy of Screw, Nut, and Rollers: Lead errors ΔPh cause phase mismatches in thread engagements, reducing the number of effective contact points. The cumulative lead error over the engagement length Le affects load sharing:

$$ \Delta L_{cum} = \Delta P_h \cdot \frac{L_e}{P_h} $$

This can lead to some rollers carrying disproportionately high loads in the planetary roller screw assembly.

- Straightness of Screw and Rollers: Bending or curvature deviations δcurve cause non-uniform contact along the length. The contact pressure distribution p(x) becomes uneven, modeled as:

$$ p(x) = p_0 \left(1 + \frac{\delta_{curve}}{h} \cdot x\right) $$

where p0 is the nominal pressure and x is the axial position. This increases local stress and reduces overall承载.

Given these factors, the actual load capacity of a planetary roller screw assembly often falls short of theoretical values. In contrast, ball screw assemblies have evolved with heavy-duty designs that enhance their load capacity. For instance, by increasing ball diameter, adding more ball circuits, and optimizing raceway profiles, manufacturers have achieved significant improvements. Below, I present a comparison of load ratings for both assemblies, based on available data from industry sources. The tables illustrate that for small sizes and leads, the planetary roller screw assembly may have an advantage, but for larger sizes, ball screw assemblies can compete or even surpass.

| Size (Diameter × Lead) | Manufacturer | Outer Diameter (mm) | Dynamic Load Rating (kN) | Static Load Rating (kN) |

|---|---|---|---|---|

| 32 × 10 | Manufacturer A | 58 | 102.9 | 191.3 |

| 32 × 10 | Manufacturer B | 58 | 71 | 169 |

| 40 × 10 | Manufacturer A | 66 | 162.6 | 336 |

| 40 × 10 | Manufacturer B | 66 | 120 | 344 |

| 50 × 10 | Manufacturer A | 78 | 179.1 | 462.7 |

| 50 × 10 | Manufacturer B | 75 | 133 | 435 |

| 63 × 16 | Manufacturer A | 105 | 577.1 | 1461.3 |

| 63 × 16 | Manufacturer B | 105 | 450 | 1450 |

| Size (Diameter × Lead) | Manufacturer | Outer Diameter (mm) | Dynamic Load Rating (kN) | Static Load Rating (kN) |

|---|---|---|---|---|

| 30 × 10 | Manufacturer C | 64 | 101 | 174 |

| 30 × 10 | Manufacturer D | 62 | 88.1 | 150.6 |

| 30 × 10 | Manufacturer E | 63.5 | 51 | 156 |

| 39 × 10 | Manufacturer D | 80 | 124.4 | 247.4 |

| 39 × 10 | Manufacturer E | 80 | 80 | 204 |

| 48 × 10 | Manufacturer C | 100 | 220 | 475 |

| 48 × 10 | Manufacturer D | 100 | 207 | 412 |

| 64 × 18 | Manufacturer D | 115 | 238.1 | 612.3 |

The data show that for smaller specifications like 30 mm diameter, the planetary roller screw assembly can offer higher dynamic and static loads compared to some ball screw assemblies. However, as size increases, ball screw assemblies with heavy-duty designs catch up or exceed, thanks to advancements like larger balls and multiple circuits. This underscores the importance of design evolution in ball screw technology, which has addressed load capacity limitations through innovation.

Regarding applications, the planetary roller screw assembly is often proposed for aerospace due to its smooth motion and potential high load density. However, reliability is paramount in aerospace, where components cannot be serviced mid-mission. The complexity of the planetary roller screw assembly introduces multiple failure modes, such as thread wear, roller skew, and contact point degradation. In contrast, ball screw assemblies have a proven track record in aerospace applications, with simpler structures that facilitate high precision and reliability. For example, in aircraft actuation systems, ball screw assemblies are widely used for flight control surfaces, landing gear, and other critical functions. Their maturity and robustness make them preferred despite the theoretical advantages of planetary roller screw assemblies.

Moreover, the manufacturing challenges of planetary roller screw assemblies cannot be overlooked. The multi-start threads require ultra-precise machining, and the roller profiles demand specialized grinding. Assembly is meticulous, often involving selective fitting to achieve proper preload. These factors increase cost and reduce yield, limiting scalability. On the other hand, ball screw assemblies benefit from standardized processes and mass production, resulting in cost-effectiveness and consistent quality.

To quantify the efficiency of a planetary roller screw assembly, I can derive an expression based on friction losses. The overall efficiency η is influenced by rolling friction and sliding friction at contact points:

$$ \eta = \frac{P_{out}}{P_{in}} = \frac{F \cdot v}{T \cdot \omega} $$

where F is the output force, v is the linear velocity, T is the input torque, and ω is the angular velocity. For a planetary roller screw assembly, the torque includes components due to rolling resistance and sliding friction:

$$ T = T_{rolling} + T_{sliding} = \mu_r \cdot F \cdot \frac{P_h}{2\pi} + \mu_s \cdot F_n \cdot r_{eff} $$

Here, μr is the rolling friction coefficient, μs is the sliding friction coefficient, Fn is the normal force at contacts, and reff is an effective radius. In practice, η for planetary roller screw assemblies rarely exceeds 90%, while ball screw assemblies often achieve above 90% due to lower friction coefficients and better surface finishes.

In terms of future research, efforts to improve the planetary roller screw assembly should focus on mitigating the factors that reduce load capacity. Advanced manufacturing techniques like additive manufacturing could enable more precise thread forms and integrated components. Simulation tools, such as finite element analysis (FEA), can optimize contact stress distribution. For instance, modeling the Hertzian contact in a planetary roller screw assembly with realistic tolerances can predict failure points and guide design adjustments. Additionally, material innovations, such as high-strength alloys or coatings, could enhance wear resistance and fatigue life.

Nevertheless, the fundamental complexity of the planetary roller screw assembly remains a barrier. For high-reliability applications like aerospace, the risk associated with multiple potential failure modes may outweigh the benefits. Therefore, I recommend cautious evaluation when considering planetary roller screw assemblies for critical systems. In many cases, advanced ball screw assemblies with heavy-duty features offer a more balanced solution, combining high load capacity, efficiency, and proven reliability.

In conclusion, the planetary roller screw assembly is a fascinating mechanical design with theoretical advantages in load capacity and smoothness. However, its practical performance is hampered by manufacturing intricacies and reliability concerns. Through this analysis, I have highlighted the key factors affecting its承载, compared it with ball screw assemblies, and discussed its applicability. The planetary roller screw assembly may find niche applications where its specific benefits are critical, but for broad use, especially in aerospace, ball screw assemblies continue to dominate due to their simplicity and reliability. Ongoing research may address some limitations, but the core challenges of the planetary roller screw assembly must be carefully managed to ensure successful deployment.